Low-carbon self-adhesive paper, as well as label and labeling method and labeling head thereof

A labeling and labeling technology, applied in the directions of labels, labeling machines, transportation and packaging, can solve the problems of ultra-thin self-adhesive labels that cannot be machine-applied, and promote environmental protection and low carbon, reduce thickness, and reduce waste of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Make a low-carb self-adhesive paper.

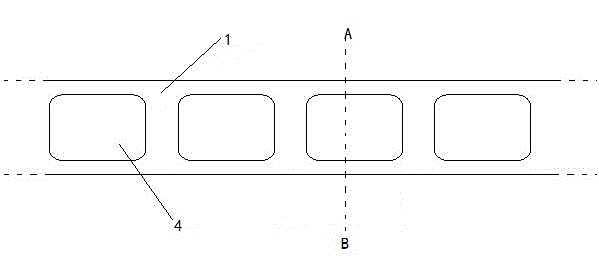

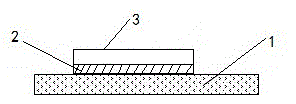

[0077] Such as figure 2 , image 3 , Figure 4 As shown, choose a 85g / m 2 Glassine release paper is used as the release paper (1) layer, and then a 12μm thick transparent PET film is selected as the surface paper (3) layer, and a self-adhesive (2) layer is coated between the two, Thereby make a kind of self-adhesive material standby.

[0078] Separate the release paper (1) layer of the above-mentioned spare self-adhesive material from the surface paper (3) layer, and then use a punching machine to punch some micropores (13) with a diameter of 0.1-2mm on the release paper (1) layer, Then compound it back to the surface paper (3) layer to form a breathable release paper (1) self-adhesive paper—the low-carbon self-adhesive paper of the present invention.

[0079] It is also possible to load the above-mentioned spare self-adhesive materials onto the self-adhesive label die-cutting machine, and die-cut the release paper (1) layer ...

Embodiment 2

[0082] Print a low-carbon self-adhesive label.

[0083] Such as figure 2 , image 3 , Figure 4 As shown, the air-permeable release paper (1) self-adhesive paper made in the above-mentioned embodiment 1 is used to print a self-adhesive label (4) with a certain geometric shape.

[0084] Then, a laser die-cutting machine is used for die-cutting and discharging waste, and a breathable release paper (1) self-adhesive label (4)--the low-carbon self-adhesive label of the present invention.

Embodiment 3

[0086] A low-carbon self-adhesive labeling method.

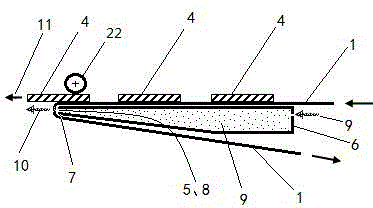

[0087] Such as figure 1 As shown, in the vicinity of the position of the front edge (7) of the current self-adhesive labeling machine (6), set some blowing holes (5), or set up a blowing slot (8), and compress the air (9 ) leads to the blowing hole (5) or the blowing slit (8), so that it is blown out from the blowing hole (5) or the blowing slit (8), and the blowing direction (10) is consistent with the direction of the label.

[0088] Load the air-permeable release paper (1) and the self-adhesive label (4) prepared in the second embodiment above on the labeling machine, and label the product. When labeling, the compressed air (9) is blown out through the release paper (1) through the blowing hole (5) or the blowing slit (8) at the front ridgeline (7), which can help the self-adhesive label (4) Tilt. In this way, the automatic machine-attaching task of the ultra-thin self-adhesive label (4) with a thickness of 12 μm is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap