Calibration system and calibration method for deflecting direction of streak tube and cathode surface

A technology of deflection direction and calibration system, which is applied in the factory adjustment of electric tubes/lamps, etc., to achieve the effects of improving efficiency, good economic benefits and social significance, and convenient and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

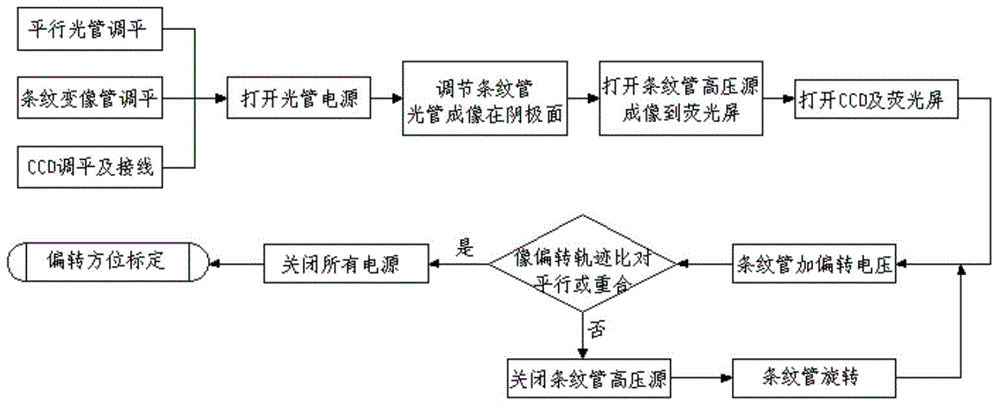

[0047] The method of the present invention includes two systems of deflection direction calibration and cathode surface calibration:

[0048] 1. The deflection direction calibration system:

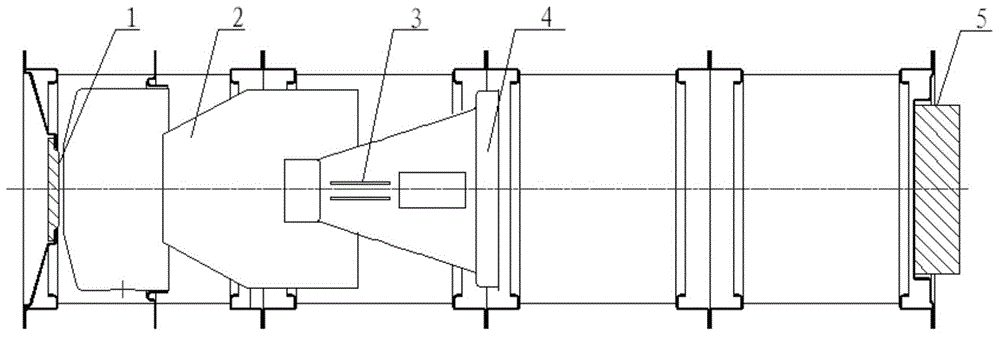

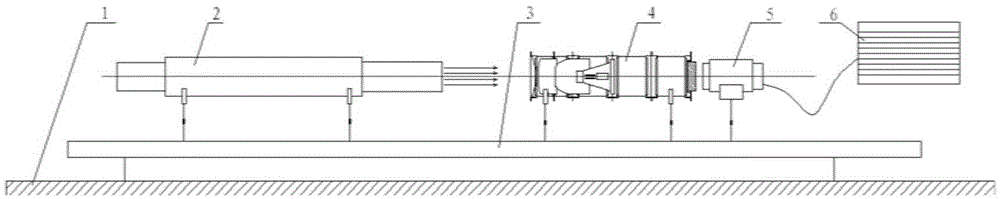

[0049] The schematic diagram of the deflection direction calibration system of the fringe image transformation tube is as follows: figure 2 As shown, it is mainly composed of an optical platform, a collimator, a fixed guide rail and a slider, a striped image transformation tube, a CCD and a display. Among them, the optical platform is used as a test platform, and the guide rail is installed on the optical test platform; there is a divided cathode in the collimator to provide light source for the calibration of the stripe image transformation tube; The image is formed on the cathode surface of the stripe image transformation tube; the CCD and the display are used as the image acquisition and display unit for the final imaging of the stripe image transformation tube.

[0050] The technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com