Laser annealing equipment and method for improving silicon wafer surface roughness by adopting laser annealing equipment

A laser annealing, silicon wafer surface technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of prone to debris, increase process time and cost, and achieve the effect of improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the accompanying drawings, the details are as follows:

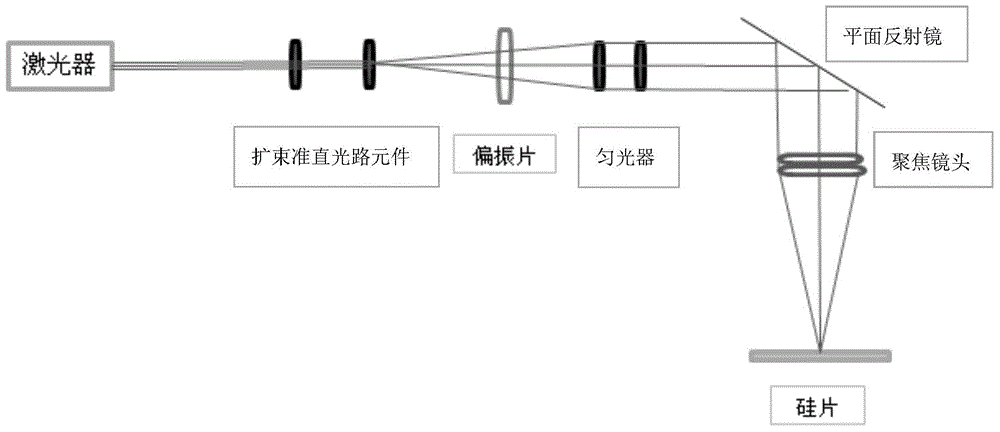

[0010] In this embodiment, the optical path system of the laser annealing equipment has been newly designed and transformed, such as figure 1 As shown, in addition to the conventional optical components such as the original laser, beam expander and collimator optical path elements, homogenizer and focusing lens, a set of polarizers is added between the beam expander collimator optical path elements and the light homogenizer, so that The laser light emitted by the laser becomes polarized light with a fixed direction after passing through the set of polarizers.

[0011] Polarizers include but not limited to 1 / 4, 1 / 2 waveplates. The number of polarizers can be one piece or one set. The polarization direction is not particularly limited, and may be any direction.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com