A kind of manufacturing method of punching aluminum foil rfid radio frequency antenna

The technology of a radio frequency antenna and a manufacturing method, which is applied in the field of RFID radio frequency technology application, can solve the problems of high manufacturing cost, affect the smooth surface, increase the thickness of aluminum foil film, etc., and achieve the effects of reduced manufacturing cost, simple manufacturing process, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

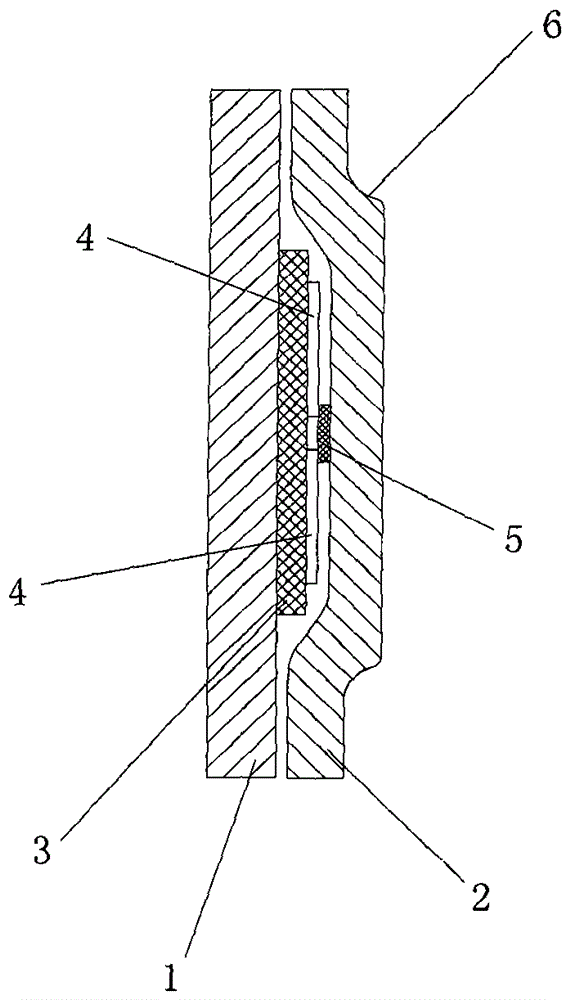

[0110] like figure 1 Shown is the sectional view of the radio frequency label comprising radio frequency antenna that adopts prior art method to make, by figure 1 It can be seen that between the bottom paper (film) 1 and the upper paper (film) 2, the PET bottom film 3 on the radio frequency antenna and the aluminum foil antenna 4 and the radio frequency chip 5 of the chemical etching process are made by traditional technology, resulting in the PET bottom film on the surface of the label. The edge of the membrane is raised6.

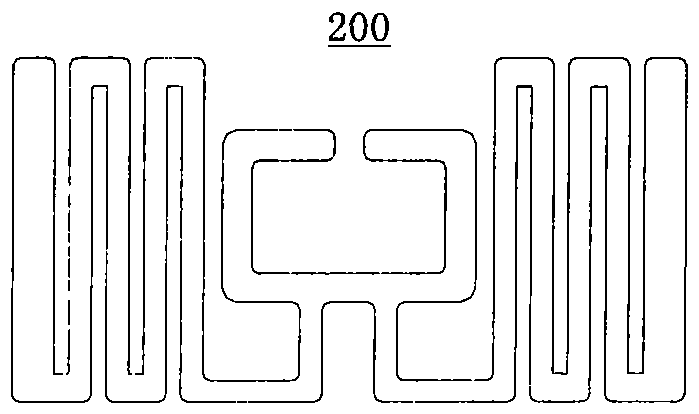

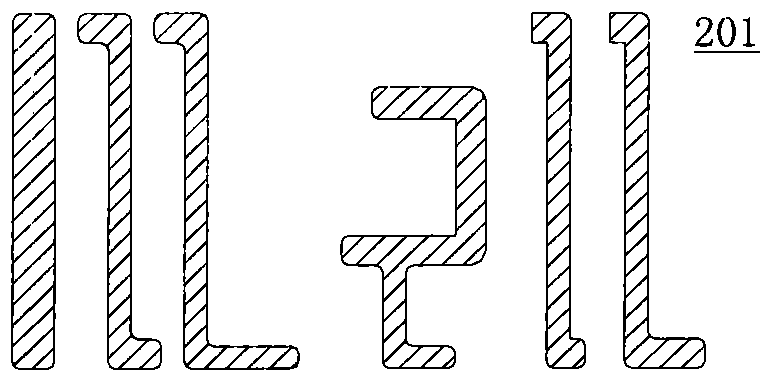

[0111] like figure 2 , 2A , 2B, and 2C, as an open-loop UHF radio frequency antenna, usually the 2D chip antenna resonator is an open-loop pattern (see figure 2 ), the open-loop radio frequency antenna pattern 200 is decomposed into two parts, namely the first group of line segment figures 201 and the second group of line segment figures 202, both of which are line segment figures. Two aluminum foil materials are cut, and the aluminum foil line segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com