Central air supply, heat dissipation and noise reduction system for motor group

A technology of centralized air supply, heat dissipation and noise reduction, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems that the noise reduction effect cannot meet the ideal requirements, the manufacturing of fan blades is difficult, and the user's on-site requirements are high. Improve the cooling and heat dissipation effect, the noise reduction effect is obvious, and the effect of solving the problem of load-bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

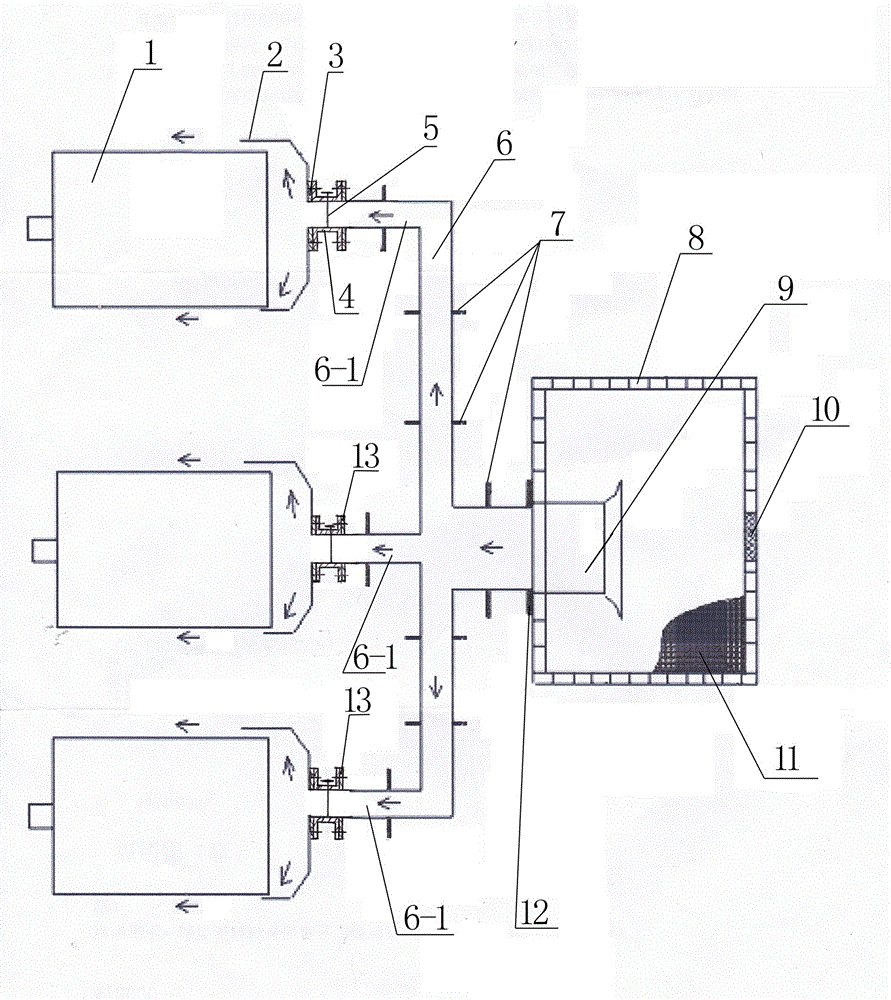

[0021] see figure 1 , the air supply and heat dissipation noise reduction system in the motor cluster of the present invention includes a motor 1, a noise reduction room 8, a blower fan 9 and an air duct, wherein the motor 1 is not provided with a cooling fan, and the motor wind cover 2 at its tail end is not provided with a ventilation screen window , only an air inlet is set at the center of the end of the motor windshield 2, the windshield flange 3 is housed on the air inlet, and the sound-absorbing room 8 is arranged in the factory or in each workshop, and the wall of the sound-absorbing room 8 is a sound-absorbing brick Masonry structure, the door 10 is a sandwich wood structure, the middle of the interlayer is filled with sound-absorbing cotton, the roof is a cement cast-in-place structure, and there is a sound-absorbing board ceiling 11, and the sound-absorbing board in the sound-absorbing board ceiling 11 can use rock wool sound-absorbing board Or polyester fiber sound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com