Multiple-winding high-voltage motor drive control system having complete redundant backup function

A high-voltage motor, fully redundant technology, applied in the control system, vector control system, motor generator control, etc., can solve the problems that the vector control cannot be fully compatible, redundant backup cannot be realized, and the number of motor windings is different, so as to improve The effect of reliability, cost realization, and high communication rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

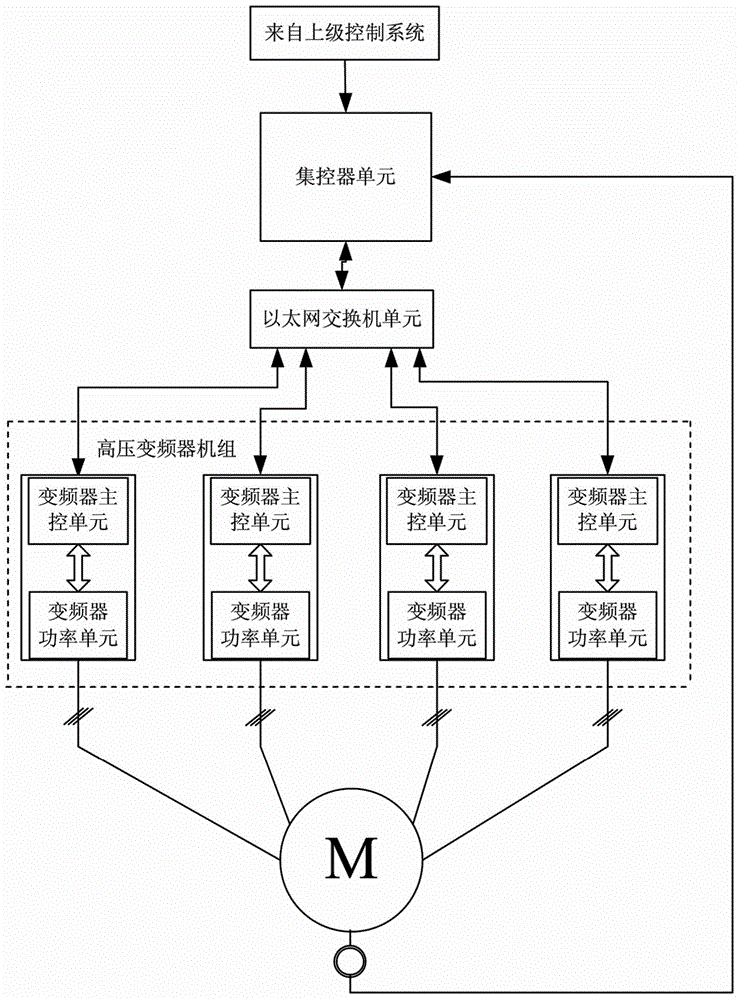

[0020] According to attached figure 1 , the present invention takes a 4-winding high-voltage AC motor as an example. A high-voltage multi-winding motor drive control system with complete redundancy backup function of the present invention includes a high-voltage frequency converter unit, an Ethernet switch unit and a centralized controller unit. The centralized controller unit is connected to the Ethernet switch unit, the Ethernet switch unit is connected to the main control unit of the high-voltage frequency converter unit, and the centralized controller unit is also connected to the motor speed sensor. The centralized controller unit is connected to the Ethernet switch unit through optical fibers or cables, and the main control units of each high-voltage inverter in the high-voltage inverter unit are also connected to the Ethernet switch uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com