Light field camera

A light field camera and lens technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems of blurry and poor quality of captured pictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

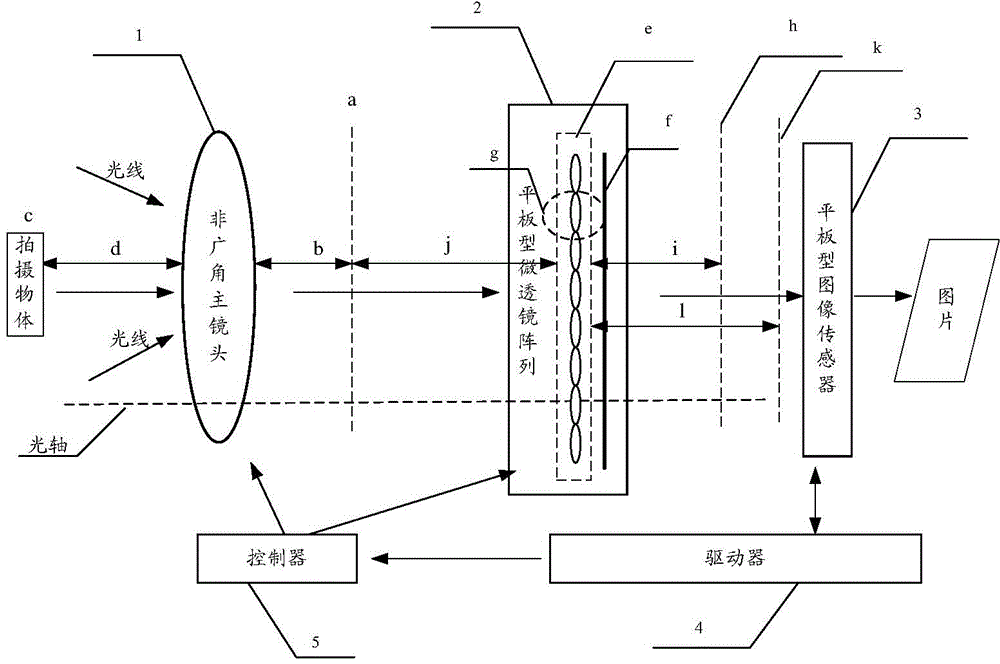

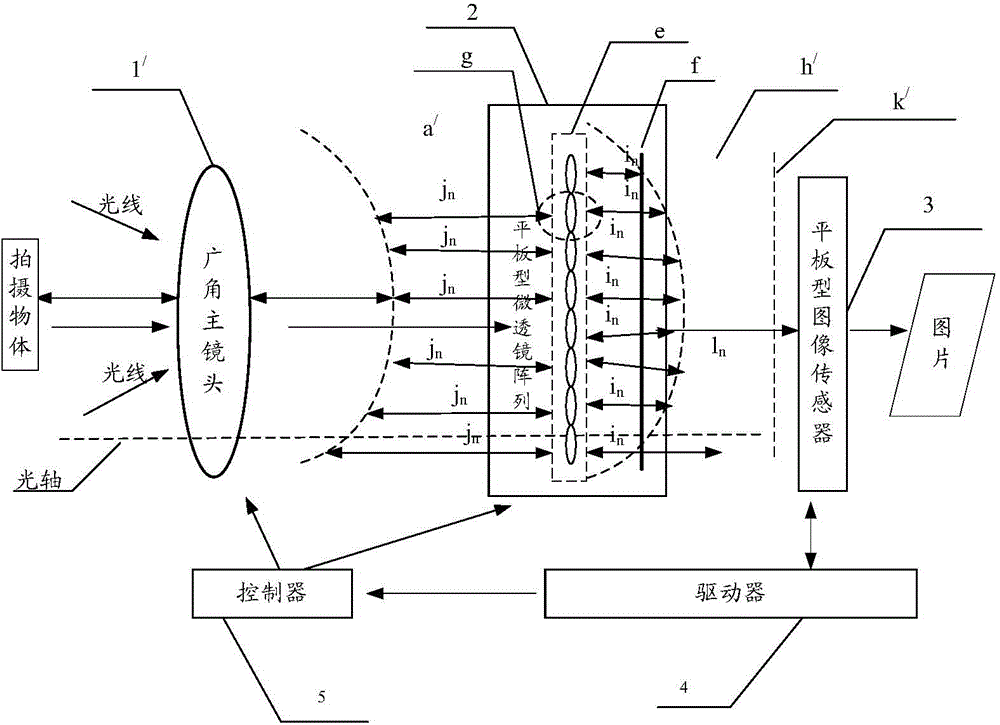

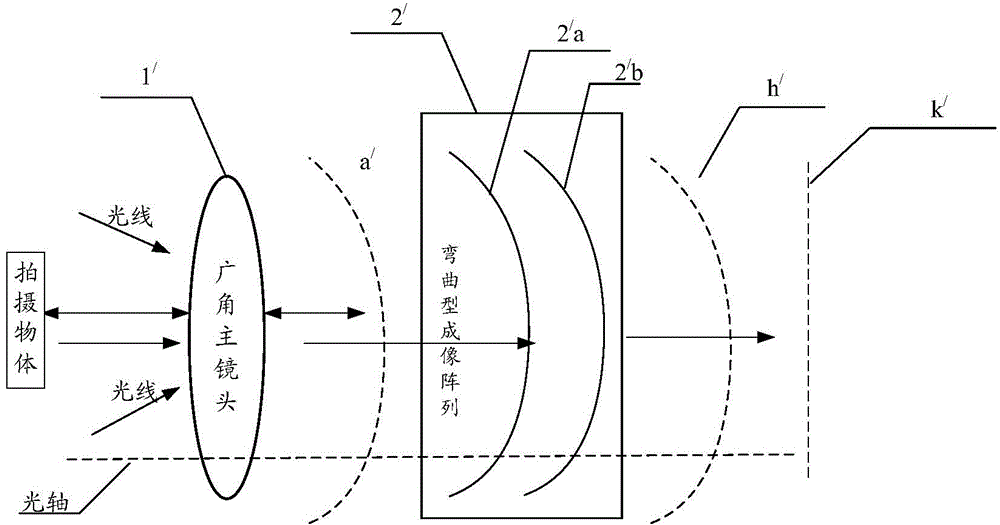

[0040] In order to solve the problem that the light field camera in the prior art uses a wide-angle lens to take pictures that are blurry and poor in quality, in the embodiment of the present invention, two kinds of light field cameras are proposed. In one of the solutions, due to the curved The curved shape of the microlens array and the curved shape of the curved image sensor are the same as the curved shape of the virtual image plane of the wide-angle main lens, and the reciprocal of the vertical distance between the curved microlens array and the curved image sensor is the same as that of the curved image sensor. The sum of the reciprocals of the vertical distances between the microlens array and the virtual image plane of the wide-angle main lens is equal to the reciprocal of the focal length of the curved microlens array, thus solving the blurred pictures that exist when the light field camera uses a wide-angle lens to shoot , the problem of poor quality; in another schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com