Simvastatin nano suspension and preparation method thereof

A nano-suspension, simvastatin technology, which is applied in pharmaceutical formulations, medical preparations with inactive ingredients, and medical preparations containing active ingredients, etc. narrow range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

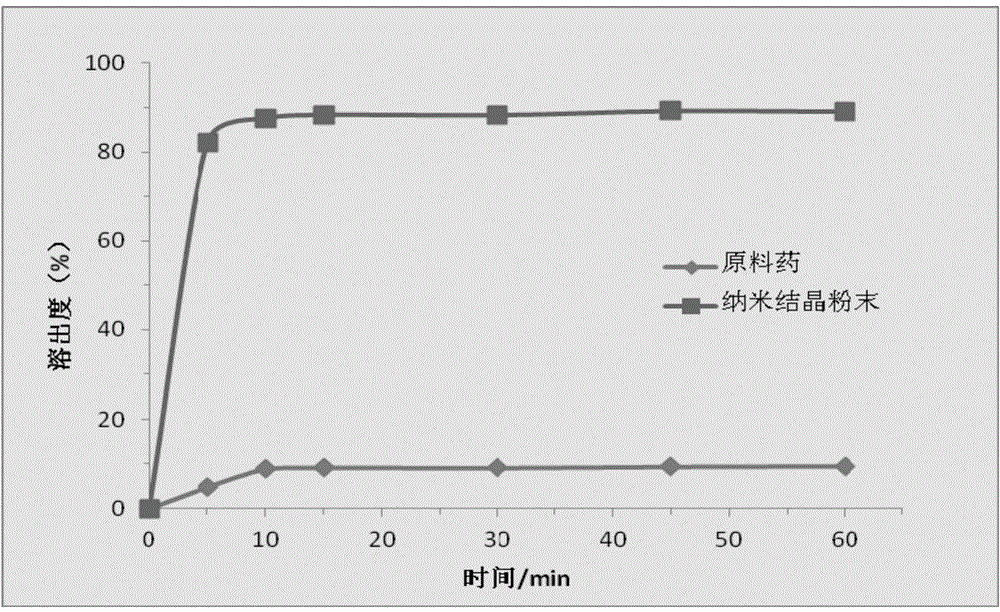

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Another aspect of the present invention provides a method for preparing the simvastatin nanosuspension of the present invention, the method comprising the following steps:

[0050] (1) Crush 1 part by weight of simvastatin;

[0051] (2) Dissolving 0.5-20 parts by weight of stabilizer in a solvent, and adding the simvastatin obtained in step (1) to obtain a suspension;

[0052] (3) Grind the suspension obtained in step (2) to obtain a nanosuspension,

[0053] The stabilizer is selected from lecithin, poloxamer 188, sodium lauryl sulfate, hydroxypropyl cellulose, hypromellose, polyvinylpyrrolidone, docusate sodium, and combinations thereof.

[0054] In the present invention, the pulverization step is conventional. A person of ordinary skill in the art can directly determine how to perform the pulverization step based on the description of the present invention combined with the prior art. In a preferred embodiment of the present invention, the pulverization step includes jet pulv...

Embodiment 1

[0083] Weigh PVP-K901.5g and SDS0.5g into 100ml of distilled water, dissolve it completely by ultrasound, slowly add 0.5g of simvastatin crushed by airflow under magnetic stirring, and cut for 5 minutes with a high-speed shearing machine at 10000rpm. Get the initial suspension. Then pour the initial suspension into the feed hopper for grinding. The grinding conditions are as follows: the particle size of the zirconia beads is 0.1 mm, the amount of zirconia beads is 60 ml, and the rotation speed is 3000 rpm. A sample was taken 20 minutes later, and the measured particle size was 286.6 nm and the potential was -28.5 mv.

Embodiment 2

[0085] Weigh 1.0g of HPMC and 0.5g of SDS into 100ml of distilled water, dissolve it completely by ultrasound, slowly add 0.5g of simvastatin crushed by airflow under magnetic stirring, and cut with a high-speed shearing machine at 10000rpm for 5 minutes. Suspension. Then pour the initial suspension into the feed hopper for grinding. The grinding conditions are as follows: the particle size of the zirconia beads is 0.1 mm, the amount of zirconia beads is 60 ml, and the rotation speed is 3000 rpm. A sample was taken after 20 minutes, and the particle size was 309.5 nm and the potential was -30.2 mv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com