Safe high vibration strength elliptical vibromill

A technology of elliptical vibration and vibration intensity, which is applied in the direction of grain processing, etc., can solve the problems of lack of energy in the lower cylinder, difficulty in feeding, and high requirements for the installation foundation, so as to reduce feeding resistance, improve work efficiency, and work safely and reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

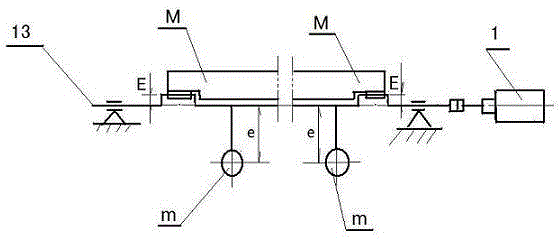

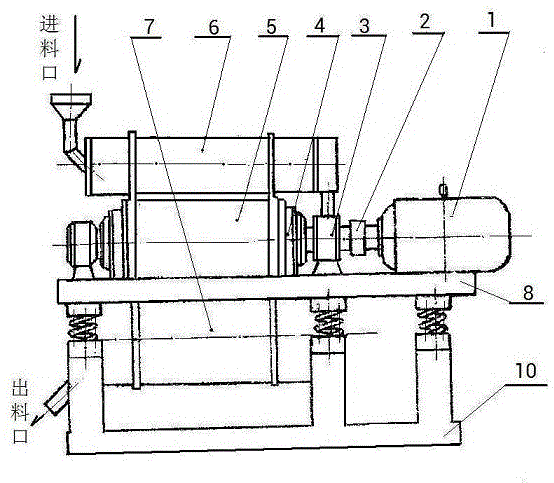

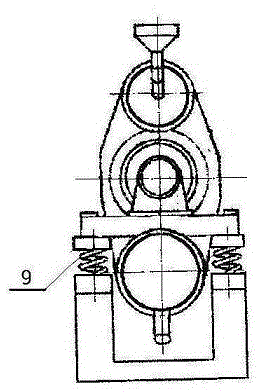

[0036] like Figure 1~2 As shown, it is a safe type high-vibration intensity elliptical vibrating mill of the present invention, including a motor 1, a shaft coupling 2, a bearing seat 3, a flange plate 4 connecting the cylinder holder, a cylinder holder 5, an upper cylinder body 6, and a lower cylinder body 7 , frame 8, spring 9, base 10, eccentric block 11, weight adjustment block 12 and main shaft 13, adopt the cylinder body that motion track is ellipse, described motor 1 is fixed on the frame 8, and motor 1 passes shaft coupling The device 2 is connected with the main shaft 13 of the vibration-exciting and vibration-eliminating coupling, the cylinder holder 5 is installed on the frame 8, the upper cylinder 6 is arranged on the top of the cylinder holder 5, and the lower cylinder 7 is arranged on the bottom of the frame 8 ; The upper cylinder body is provided with a feed inlet, and the lower cylinder body is provided with a discharge port; the upper cylinder body 6 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com