A washing and repairing process for organic polluted soil

A technology for organic pollution and treatment technology, applied in the field of treatment technology for contaminated soil, can solve the problems of high cost, complex process, low efficiency, etc., and achieve the effects of low treatment cost, simple process flow and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

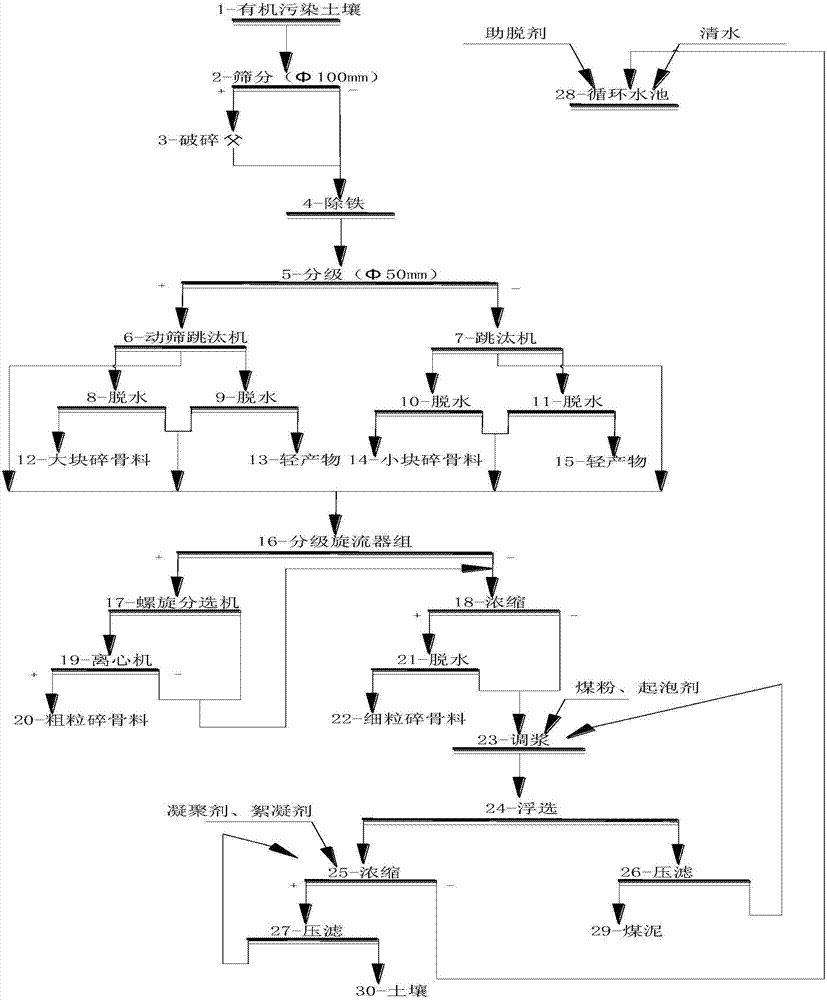

[0030] Embodiment 1: the organic polluted soil remediation process step of the present invention is as follows:

[0031] a. The organic polluted soil 1 is screened by a sieving machine 2 to 100 mm to obtain two products of +100 mm and -100 mm;

[0032] b. Use the crusher 3 to crush the +100mm product in step a and return to the -100mm product system;

[0033] c. Pass the -100mm product of step b through iron removal 4, and then use screening machine 5 to carry out 50mm screening. During the screening process, a large amount of circulating water containing desorbent is sprayed to obtain two products of 100-50mm and -50mm. Grain grade products;

[0034] d, the 100-50mm product from step a is sorted by moving screen jig 6, and the washing water adopts circulating water, and the earth and organic pollutants on the product surface are washed away in the sorting process, and two kinds of light and heavy are obtained. product;

[0035] e. Put the heavy and light products in step d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com