Refining method and device for refining thionyl chloride

A technology of thionyl chloride and purification method, which is applied in the direction of thionyl chloride, sulfur and halogen compounds, etc., can solve the problems of high by-products, can not completely separate the distillation column, etc., and achieve the effect of flexible export of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

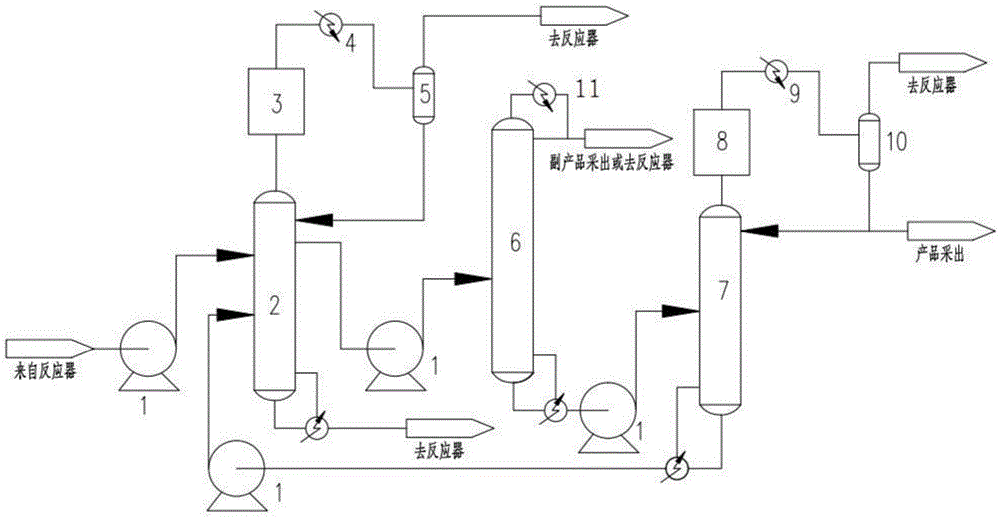

Embodiment 1

[0035] The crude product produced by the thionyl chloride synthesis reactor is pumped to the rectification tower 2, the pressure of the rectification tower is 0.002-0.012MPa, and the temperature is 77.4-90°C; the heavy components are removed through the rectification tower 2 , SOCl at the top of rectification tower 2 2 The purity of the product is 80%; the overhead flow of the rectifying tower 2 is subjected to oversulfurization treatment in the first oversulfurization tank 3, and the pressure of the first oversulfurization tank is 0.001-0.002MPa, and the temperature is 29-50°C; After the first condenser 4 is condensed, it enters the first separator 5 for gas-liquid separation. The pressure of the first separator is 0.001-0.002MPa, and the temperature is 29°C; the gas phase component Cl 2 , SO 2 enter the reaction system for recycling, the liquid phase rectification tower 2 overhead reflux; the SOCl extracted from the rectification tower 2 side line 2 , SO 2 Cl 2 and a sma...

Embodiment 2

[0037] The crude product produced by the thionyl chloride synthesis reactor is pumped to the rectification tower 2, the pressure of the rectification tower is 0.002-0.012MPa, and the temperature is 90-95°C; the heavy components are removed through the rectification tower 2 , SOCl at the top of rectification tower 2 2 The purity of the product is 80%; the overhead flow of the rectifying tower 2 carries out oversulfurization treatment in the first oversulfurization tank 3, the pressure of the first oversulfurization tank is 0.001-0.002MPa, and the temperature is 50-55°C; After the first condenser 4 is condensed, it enters the first separator 5 for gas-liquid separation. The pressure of the first separator is 0.001-0.002MPa, and the temperature is 29°C; the gas phase component Cl 2 , SO 2 enter the reaction system for recycling, the liquid phase rectification tower 2 overhead reflux; the SOCl extracted from the rectification tower 2 side line 2 , SO 2 Cl 2 and a small amount ...

Embodiment 3

[0039] The crude product produced by the thionyl chloride synthesis reactor is pumped to the rectification tower 2, the pressure of the rectification tower is 0.002-0.012MPa, and the temperature is 100-120°C; the heavy components are removed through the rectification tower 2 , SOCl at the top of rectification tower 2 2 The purity of the product is 80%; the overhead flow of the rectifying tower 2 carries out oversulfurization treatment in the first oversulfurization tank 3, and the pressure of the first oversulfurization tank is 0.001-0.002MPa, and the temperature is 70-80°C; After the first condenser 4 is condensed, it enters the first separator 5 for gas-liquid separation. The pressure of the first separator is 0.001-0.002MPa, and the temperature is 29°C; the gas phase component Cl 2 , SO 2 enter the reaction system for recycling, the liquid phase rectification tower 2 overhead reflux; the SOCl extracted from the rectification tower 2 side line 2 , SO 2 Cl 2 and a small a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com