Processing method of light foamed concrete decorating building block

A technology of foamed concrete and processing methods, which is applied in the field of blocks, can solve problems such as the utilization of unused glass properties, and achieve the effects of improving thermal performance, reducing density, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

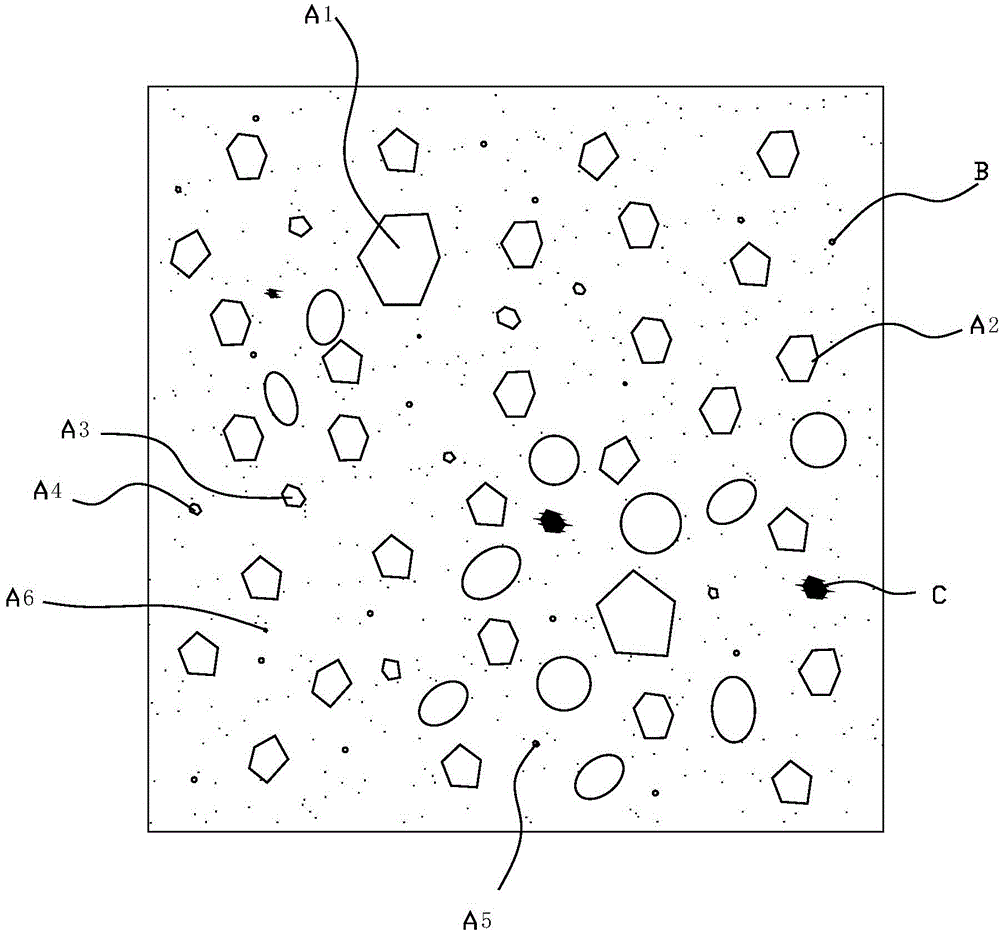

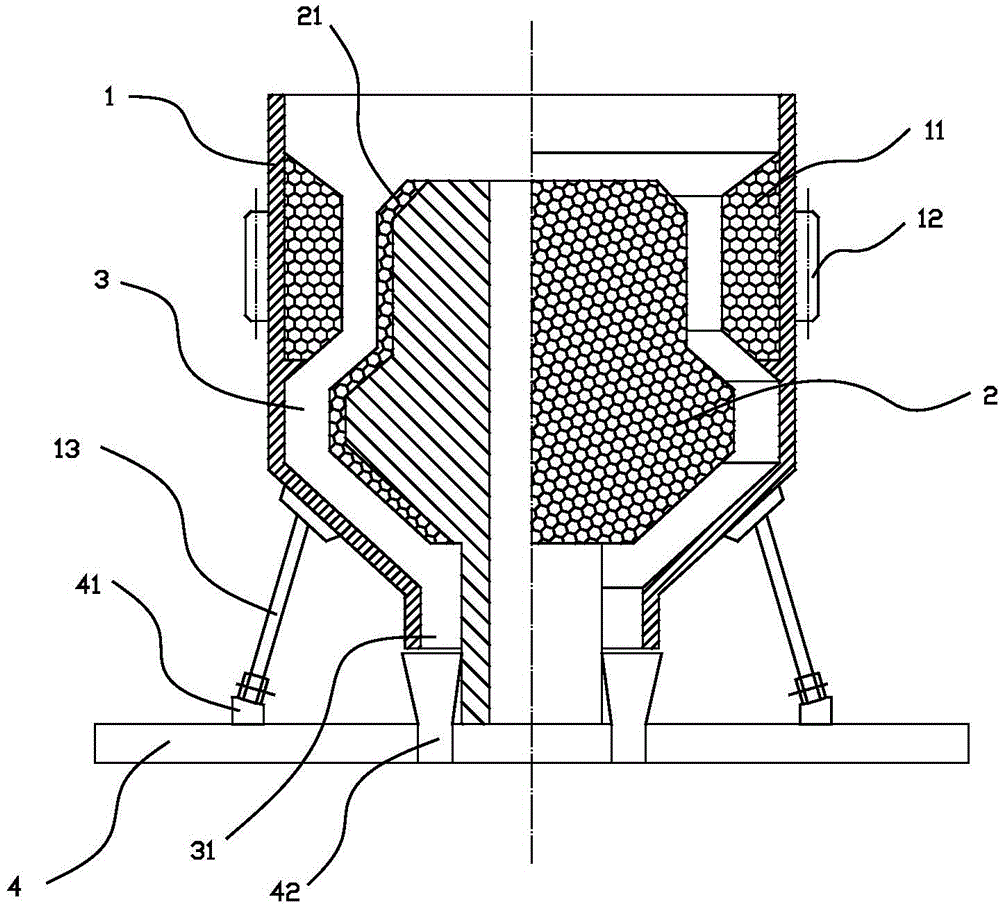

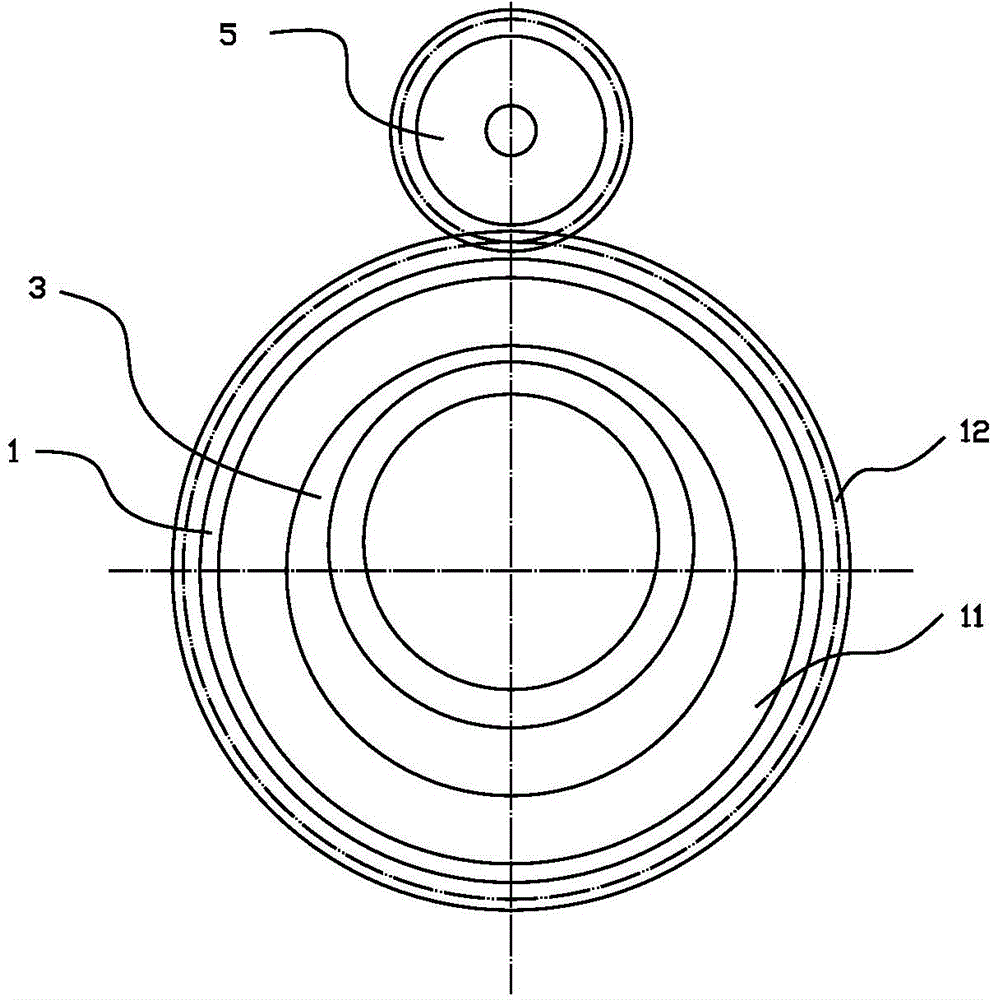

[0070] Take 180kg of cement, 200kg of glass cullet, 100kg of fly ash, 5kg of mica flakes (100 mesh), 24kg of modifier, and 260kg of water; mix evenly, then add 3kg of hydrogen peroxide, and stir at high speed to make foamed concrete for decorative masonry The block slurry is poured into the mold and then foamed, demoulded, cured, and then finished by finishing treatment;

[0071] Among them, the particle size and weight of glass cullets are: 40kg for larger than 4.75mm, 113kg for 4.75-2.36mm, 13kg for 2.36-1.18mm, 20kg for 1.18-0.60mm, 8kg for 0.60-0.30mm and 6kg for smaller than 0.30mm .

[0072] Among them, glass cullets with a particle size greater than 4.75mm, 4.75-2.36mm and 2.36-1.18mm need to be treated by chemical erosion respectively, and the chemical erosion treatment uses hydrofluoric acid solution.

[0073] Pigments are assembled according to customer requirements.

[0074] The modifier is polycarboxylate high-efficiency water reducer, aluminum sulfate, hydroxypr...

Embodiment 2

[0077] Take 400kg of cement, 500kg of glass cullet, 400kg of fly ash, 23kg of mica flakes (4kg for 20 mesh, 19kg for 50 mesh), 42kg of modifier, and 390kg of water; mix them evenly, then add hydrogen peroxide with a total weight of 17kg, and stir at a high speed. Foamed concrete decorative block slurry is poured into the mold and then foamed, demoulded, cured, and then finished by facing treatment;

[0078] Among them, the particle size and weight of glass cullets are: 100kg for more than 4.75mm, 190kg for 4.75-2.36mm, 125kg for 2.36-1.18mm, 50kg for 1.18-0.60mm, 20kg for 0.60-0.30mm and 15kg for less than 0.30mm .

[0079] Among them, glass cullets with a particle size greater than 4.75mm, 4.75-2.36mm and 2.36-1.18mm need to be treated by chemical erosion respectively, and the chemical erosion treatment uses ammonia solution.

[0080] Pigments are assembled according to customer requirements.

[0081] The modifier is polycarboxylate high-efficiency water reducer, aluminum s...

Embodiment 3

[0084] Take 300kg of cement, 300kg of glass cullet, 250kg of fly ash, 17kg of mica flakes (1kg for 20 mesh, 8kg for 50 mesh, 8kg for 100 mesh), 30kg of modifier, and 310kg of water; mix evenly, and then add 10kg of hydrogen peroxide, High-speed stirring to make the foamed concrete decorative block slurry, pouring into the mold, foaming, demoulding, curing, and finishing treatment;

[0085] Among them, the particle size and weight of glass cullets are: 27kg for larger than 4.75mm, 141kg for 4.75-2.36mm, 39kg for 2.36-1.18mm, 45kg for 1.18-0.60mm, 36kg for 0.60-0.30mm and 12kg for smaller than 0.30mm .

[0086] Among them, glass cullets with a particle size greater than 4.75mm, 4.75-2.36mm and 2.36-1.18mm need to be treated by chemical erosion respectively, and the chemical erosion treatment uses hydrofluoric acid solution.

[0087]Pigments are assembled according to customer requirements.

[0088] The modifier is polycarboxylate high-efficiency water reducer, aluminum sulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com