Energetic composite material based on three-dimensional ordered macroporous carbon skeleton and preparation method of energetic composite material

A three-dimensional ordered, composite material technology, applied in the direction of offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of easy agglomeration, large surface energy of particles, and difficulty in uniform dispersion, and achieve mild reaction conditions and energy The effect of rapid release and increased heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

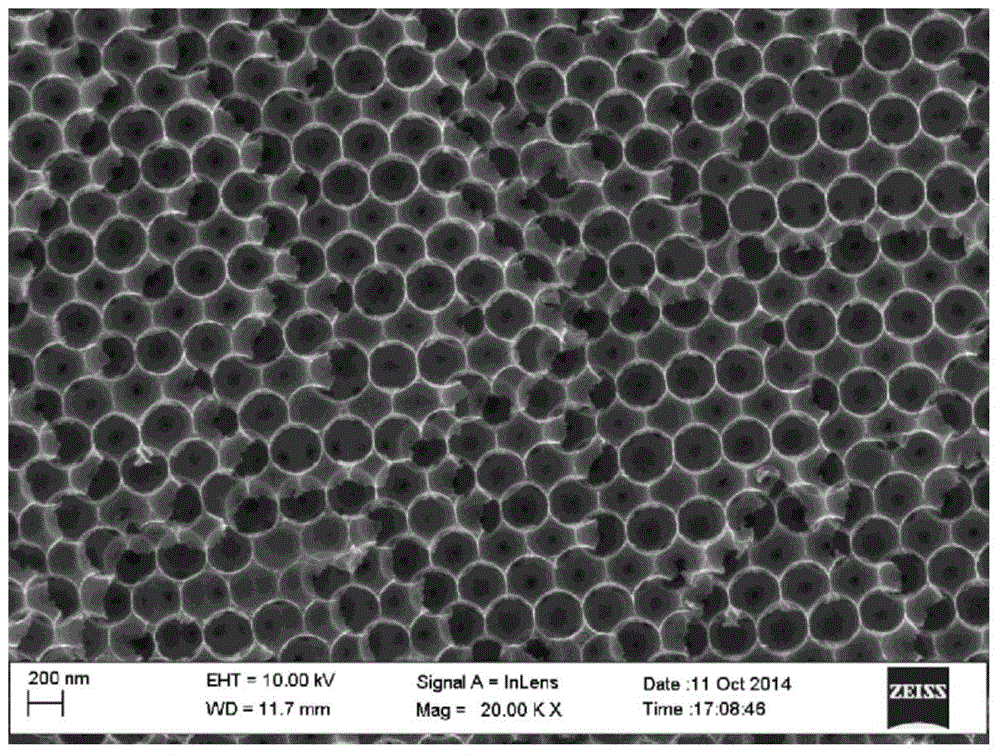

[0027] A nanocomposite energetic material composed of CL-20 and a three-dimensional ordered macroporous carbon framework with a pore diameter of 300nm. The SEM photo of the three-dimensional ordered macroporous carbon framework material with a pore diameter of 300nm and a content of CL-20 is 33.3%. figure 1 shown.

[0028] Take 0.05g of CL-20 at room temperature and dissolve it in 4.0g of acetone under magnetic stirring at a speed of 300 rpm, and stir until CL-20 is completely dissolved. Take 0.1 g of a three-dimensional ordered macroporous carbon framework material with a pore diameter of 300 nm and add it to the solution, and stir for 5 minutes under magnetic stirring at a speed of 100 rpm until uniformly mixed. The mixture was left standing at room temperature, and after all the solvent evaporated, a black-green solid was obtained. It was further dried in air at 65°C to obtain a nano energetic composite material with a CL-20 content of 33.3%. Its XRD spectrum is shown in ...

Embodiment 2

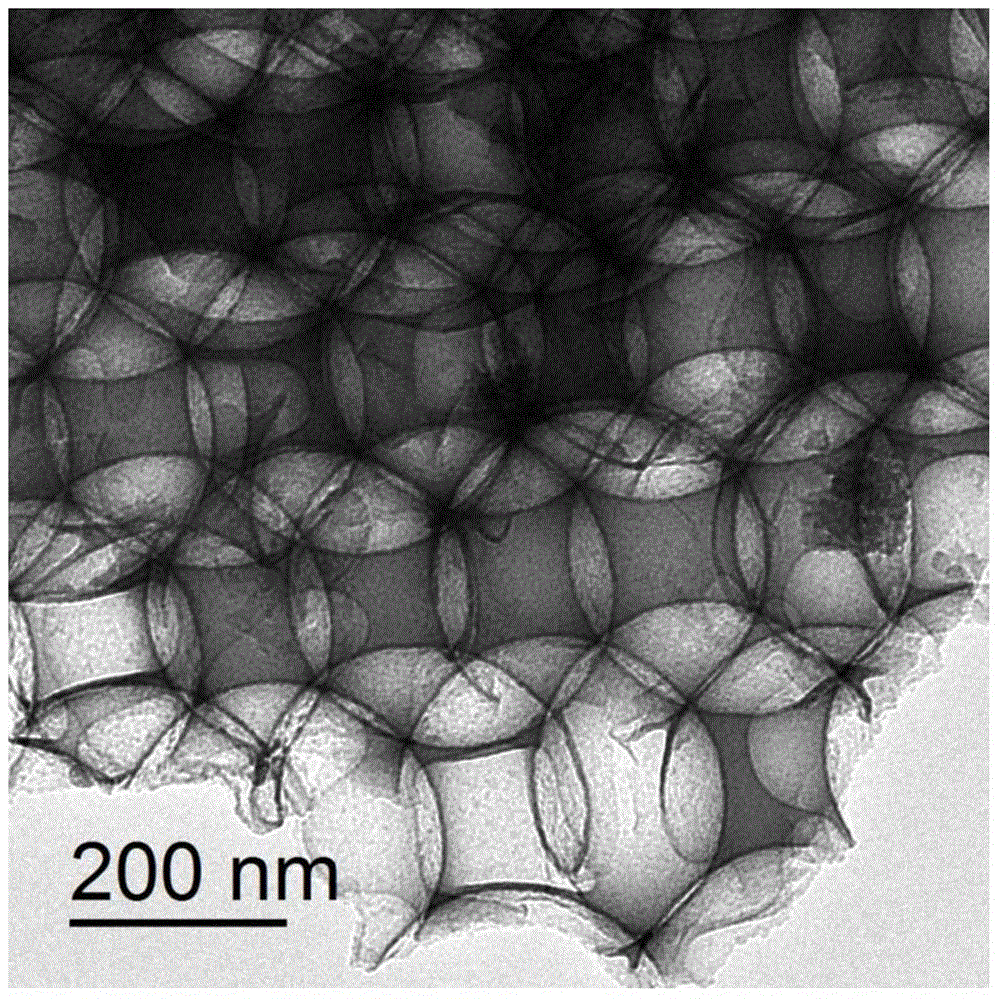

[0030] A nanocomposite energetic material composed of CL-20 and a three-dimensional ordered macroporous carbon framework with a pore diameter of 300nm. The TEM photo of the three-dimensional ordered macroporous carbon framework material with a pore diameter of 300nm and a CL-20 content of 52.4% is as follows figure 2 shown.

[0031] At room temperature, 0.11 g of CL-20 was dissolved in 4.0 g of acetone under magnetic stirring at a speed of 300 rpm, and stirred until CL-20 was completely dissolved. Take 0.1 g of a three-dimensional ordered macroporous carbon framework material with a pore diameter of 300 nm and add it to the solution, and stir for 5 minutes under magnetic stirring at a speed of 100 rpm until uniformly mixed. The mixture was left standing at room temperature, and after all the solvent evaporated, a black-green solid was obtained. It was further dried in air at 65°C to obtain a nano energetic composite material with a CL-20 content of 52.4%. Its XRD spectrum i...

Embodiment 3

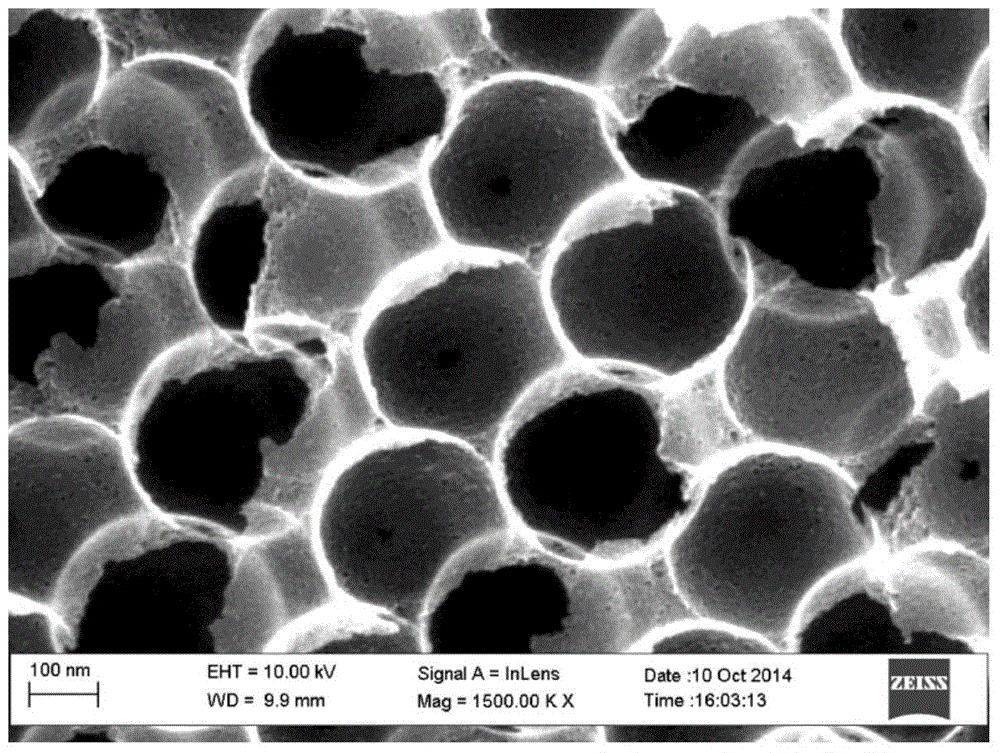

[0033] A nanocomposite energetic material composed of CL-20 and a three-dimensional ordered macroporous carbon framework with a pore size of 300nm, its SEM photo is as follows image 3 As shown, the CL-20 content is 62.9%.

[0034]Take 0.17g of CL-20 at room temperature and dissolve it in 4.0g of acetone under magnetic stirring at 300 rpm, and stir until CL-20 is completely dissolved. Take 0.1 g of a three-dimensional ordered macroporous carbon framework material with a pore diameter of 300 nm and add it to the solution, and stir for 5 minutes under magnetic stirring at a speed of 100 rpm until uniformly mixed. The mixture was left standing at room temperature, and after all the solvent evaporated, a black-green solid was obtained. It was further dried in air at 65°C to obtain a nano energetic composite material with a CL-20 content of 62.9%. Its XRD spectrum is shown in Figure 4 shown. Figure 5 DSC analysis shows that the initial decomposition temperature of the nano en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com