Fluidized bed hydrogenation method

A technology of ebullating bed and hydrogenation catalyst, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, hydrocarbon oil treatment, etc. It can solve the problems of short operation period and poor adaptability of fixed bed technology to raw materials, etc. problems, to achieve the effects of easy vulcanization, low price, and improved hydrogenation activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

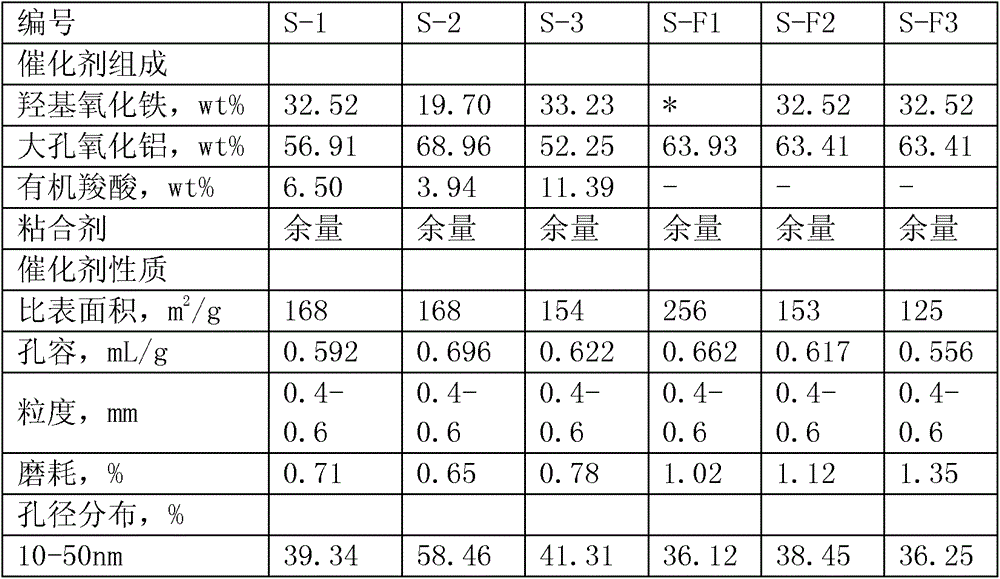

Embodiment 1

[0039] Catalyst preparation

[0040] 1. Preparation of Catalyst S-1

[0041] Weigh 1000g of ferric oxyhydroxide filter cake prepared by wet air oxidation, which contains 400g of ferric oxyhydroxide, add 80g of citric acid dissolved in 1000mL of water to it and stir to make it evenly mixed, the modification treatment time is 1h, and then filtered to obtain Modified filter cake.

[0042] Take by weighing 115g modified filter cake (wherein containing iron oxyhydroxide 40g, citric acid 8g) and 70g macroporous alumina (specific surface area 230m 2 / g, pore volume 0.91mL / g, average pore diameter 16nm), and 5g polyethylene glycol were mixed evenly and then formed into balls. mm sample as catalyst S-1.

[0043] 2. Preparation of Catalyst S-2

[0044] Other conditions are the same as S-1, except that the weight of alumina is 140g, and 15g of polyethylene glycol is prepared to obtain catalyst S-2.

[0045] 3. Preparation of Catalyst S-3

[0046] Weigh 1000g of ferric oxyhydroxide ...

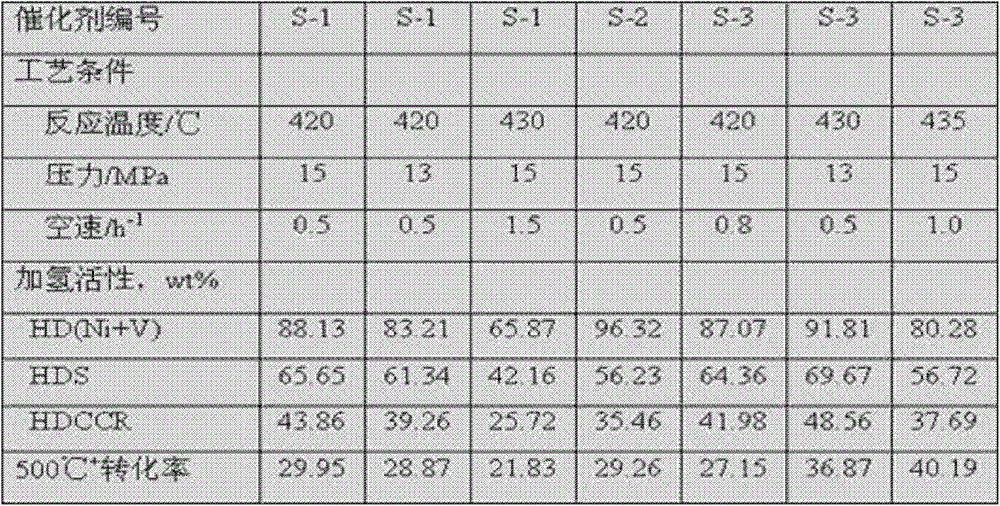

Embodiment 2

[0050] Select catalyst S-3, when the reaction temperature is 420°C, the reaction pressure is 15MPa and the space velocity is 0.5h -1 Under the conditions of normal operation for 1000h, samples were taken and analyzed at different times, and the hydrogenation activity of the catalyst at different times was shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com