Long-acting mildew-resistant odor-removing moisture-absorbing polyamide fiber and preparing method thereof

A nylon fiber and anti-mildew technology, applied in the field of anti-mildew fiber and its preparation, can solve problems such as single performance, and achieve the effects of narrow particle size distribution, promotion of dissolution, and easy dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

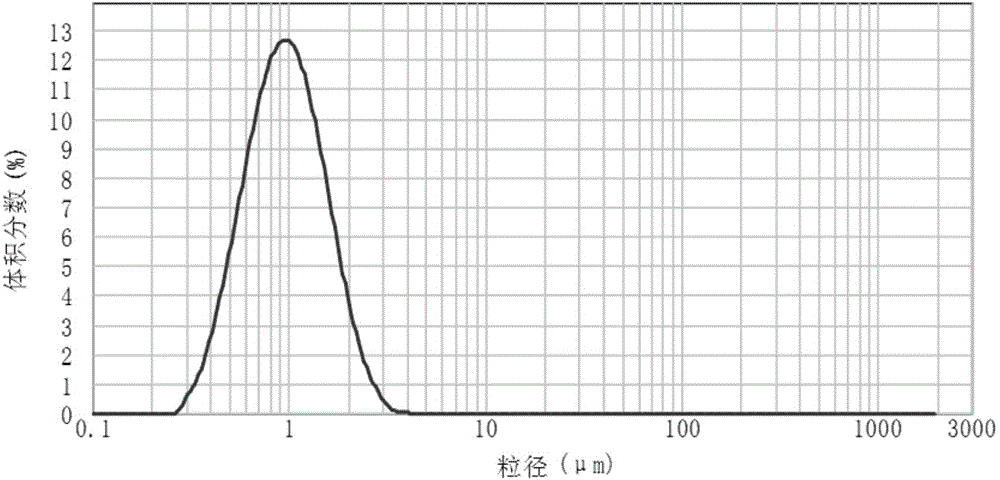

[0027] Dissolve 2.5kg of copper sulfate pentahydrate in 100kg of water, add 4kg of tetraethylenepentamine, and then add 10kg of zirconium phosphate carrier after stirring, stir for 24 hours, wash, filter, dry, and pulverize to obtain an amine content of 10%, The anti-mildew and deodorizing agent with copper content of 5.5% (both by weight percentage). The particle size distribution of the anti-mold and deodorant is as follows: figure 1 As shown, among them, d(0.1)=0.522um, d(0.5)=0.953um, d(0.9)=1.724um.

[0028] In the nylon 6 polymerization process, the above-mentioned anti-mildew and deodorizing agent is added at 1.2% to make nylon 6 slices. Long-acting anti-mold, deodorizing and hygroscopic nylon fibers are obtained by melting nylon 6 slices containing anti-mildew and deodorizing agents and spinning through a spinneret with a special-shaped cross-section of "T" shape.

[0029] The long-acting anti-mold, deodorizing and hygroscopic nylon fiber is tested according to the A...

Embodiment 2

[0031] Dissolve 6kg of copper sulfate pentahydrate in 100kg of water, add 5kg of tetraethylenepentamine, add 10kg of zirconium phosphate carrier after stirring, stir for 24 hours, wash, filter, dry, and grind to obtain amine content of 15%, containing Anti-mildew deodorizer with 10.5% copper.

[0032] In the nylon 6 polymerization process, the above-mentioned anti-mildew and deodorizing agent is added at 0.5% to make nylon 6 slices. Long-acting mildew-proof, deodorizing and hygroscopic nylon fibers are obtained by melting nylon 6 slices containing anti-mildew and deodorizing agents, and then spinning through a spinneret with a special-shaped cross-section of "Y" shape.

[0033] The long-acting anti-mold, deodorizing and hygroscopic nylon fiber is tested according to the AATCC 30-2004 standard, and the anti-mold grade is 1 and does not grow.

Embodiment 3

[0035]Dissolve 4kg of copper sulfate pentahydrate in 100kg of water, add 2.8kg of triethylenetetramine, add 10kg of zirconium phosphate carrier after stirring, stir for 24 hours, wash, filter, dry, and pulverize to obtain an amine content of 10%, Anti-mildew deodorizer with 7.9% copper.

[0036] In the nylon 6 polymerization process, the above-mentioned anti-mildew and deodorizing agent is added at 1% to make nylon 6 slices. Long-acting mildew-proof, deodorizing and hygroscopic nylon fibers are obtained by melting nylon 6 slices containing anti-mildew and deodorizing agents and spinning through a spinneret with a cross-shaped cross-section.

[0037] The long-acting anti-mold, deodorizing and hygroscopic nylon fiber is tested according to the AATCC 30-2004 standard, and the anti-mold grade is 1 and does not grow.

[0038] The long-acting anti-mildew, deodorizing and hygroscopic nylon fibers obtained in Examples 1-3 have the original excellent characteristics and anti-mold prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com