Remote control device control method for mine drilling rig

A technology of a remote control device and a control method, which is applied in the automatic control system of drilling, drilling equipment and method, and earth-moving drilling and mining, etc., can solve the problems of hidden safety hazards and low automation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

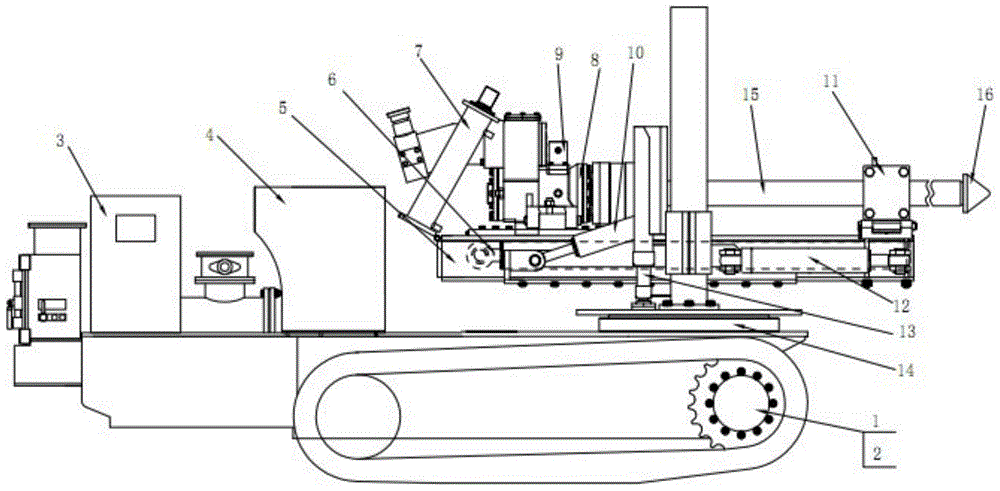

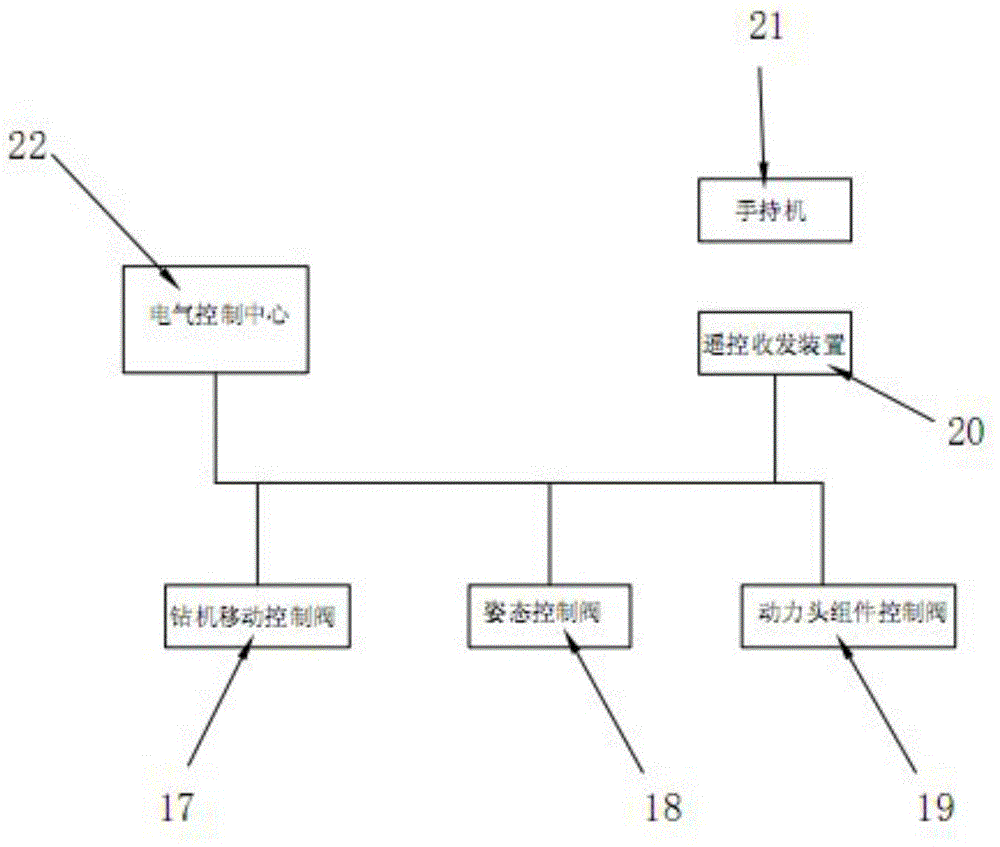

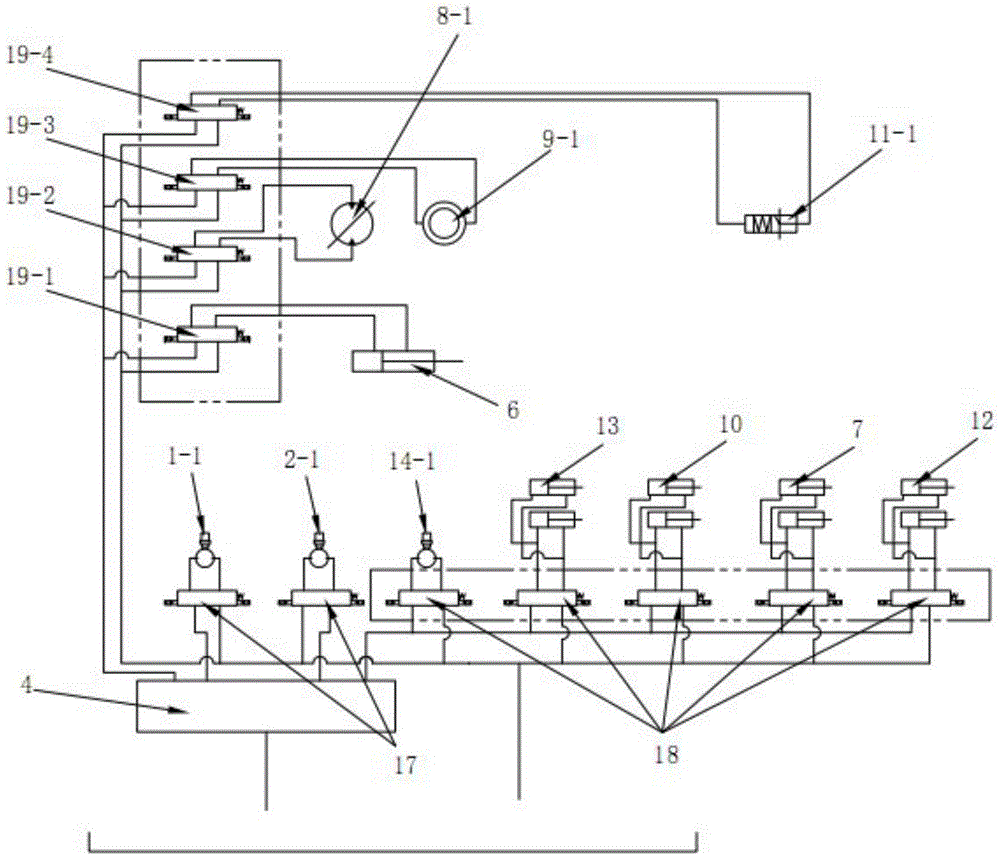

[0031] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present embodiment is used for the remote control device of the mining rig, including the drilling rig walking assembly, the drilling rig power head assembly, the drilling rig power head attitude adjustment assembly, the hydraulic pump station 3, wherein: also includes the electromagnetic control valve assembly 4, the single-chip microcomputer control unit 22 and a remote control assembly;

[0032] The drilling rig walking assembly includes a left track wheel 1, a left track wheel hydraulic motor 1-1, a right track wheel 2, and a right track wheel hydraulic motor 2-1, and the left track wheel 1 and the right track wheel 2 are respectively installed on the left side and the In the lower part of the right side, the left track wheel hydraulic motor 1-1 is installed on the left track wheel 1 for driving the left track wheel 1, and the right track wheel hydraulic motor 2-1 is installed on the right track...

Embodiment 2

[0039]For the control method of the remote control device of a mining rig, the rig movement control rocker 21-1 is provided with four functions of forward, backward, left and right, when the rig movement control rocker 21-1 is moved in the forward direction , the drilling rig movement control rocker 21-1 sends forward signal, and the forward signal is sent to the single-chip microcomputer control unit 22 through the remote control transceiver 20, and the single-chip microcomputer control unit 22 opens the electromagnetic ratio on the left track wheel hydraulic motor 1-1 after receiving the forward signal. The electromagnetic proportional reversing valve 17 on the reversing valve 17 and the right track wheel hydraulic motor 2-1 controls the left track wheel hydraulic motor 1-1 and the right track wheel hydraulic motor 2-1 to advance simultaneously, and the deflection angle of the remote lever determines the forward movement speed; when the rig movement control rocker 21-1 is tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com