Method for preparing graphene-based hollow tin dioxide lithium ion battery negative electrode material

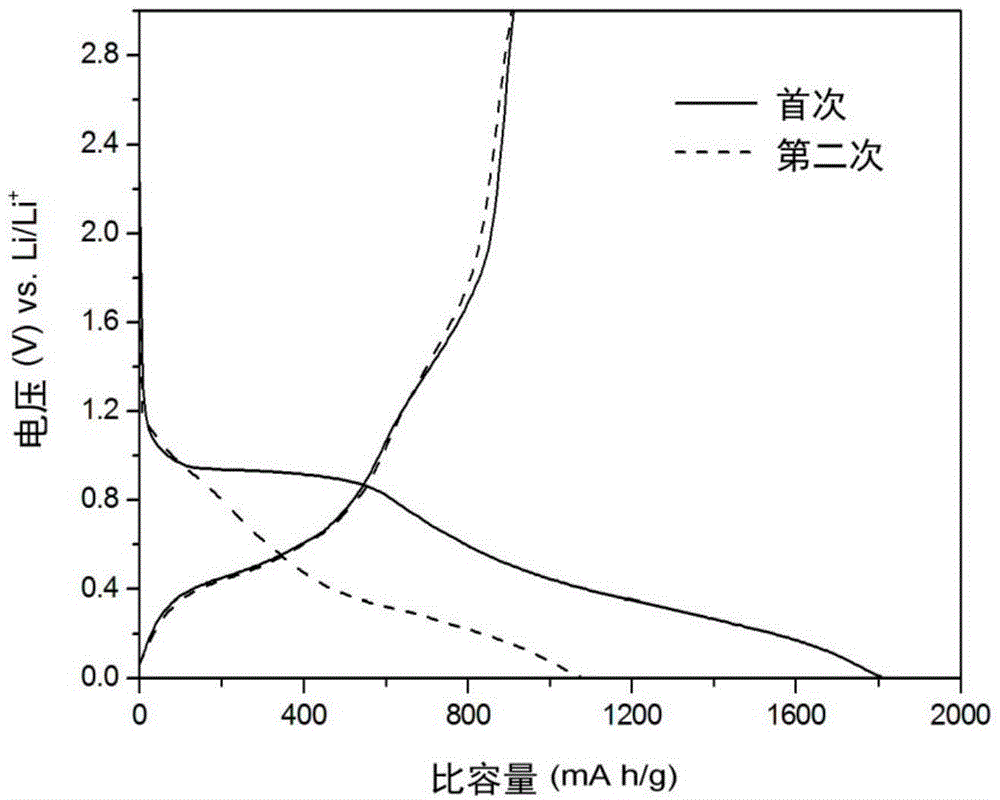

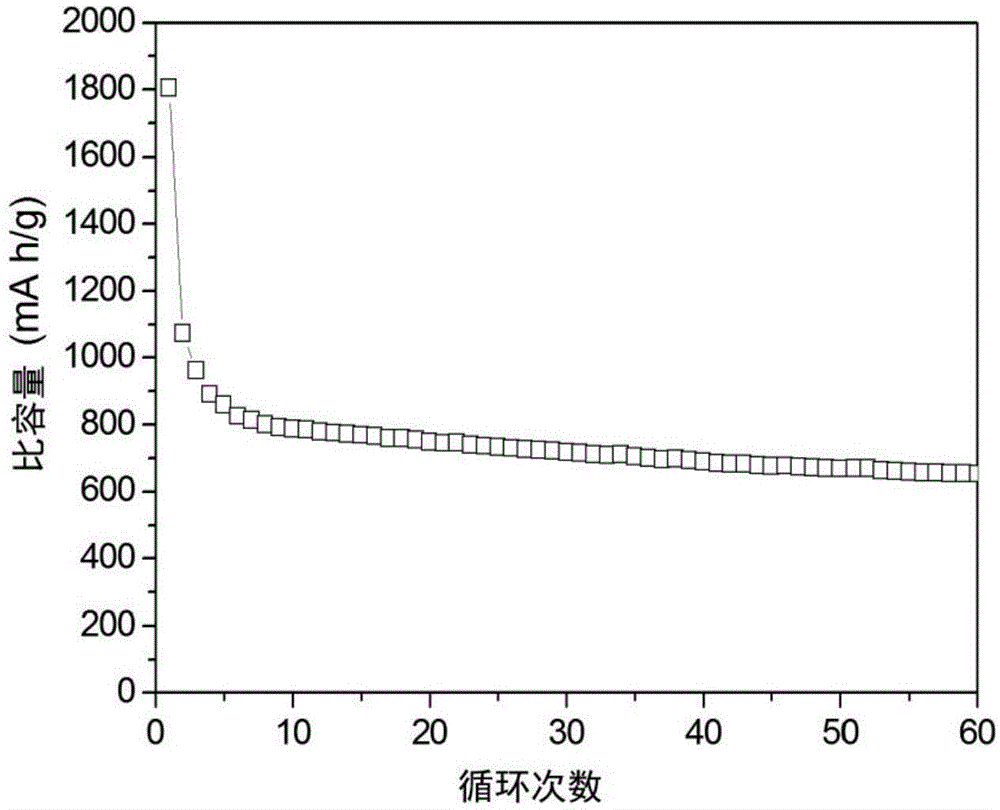

A lithium-ion battery and tin dioxide technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problems of high pollution, cumbersome operation process, etc., achieve high specific surface area, increase storage Space, the effect of improving specific capacity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a graphene-based hollow tin dioxide lithium-ion battery negative electrode material, the steps are as follows:

[0032] (1) Add 1.0 parts by weight of graphene oxide to a mixed solvent composed of 900 parts by weight of ethanol and 1900 parts by weight of deionized water, and ultrasonically vibrate for 10 minutes to obtain a stable graphene oxide dispersion;

[0033] (2) Add 13 parts by weight of potassium stannate trihydrate in the graphene oxide dispersion of step (1), after stirring for 5 minutes, add 18 parts by weight of urea, and continue stirring for 5 minutes;

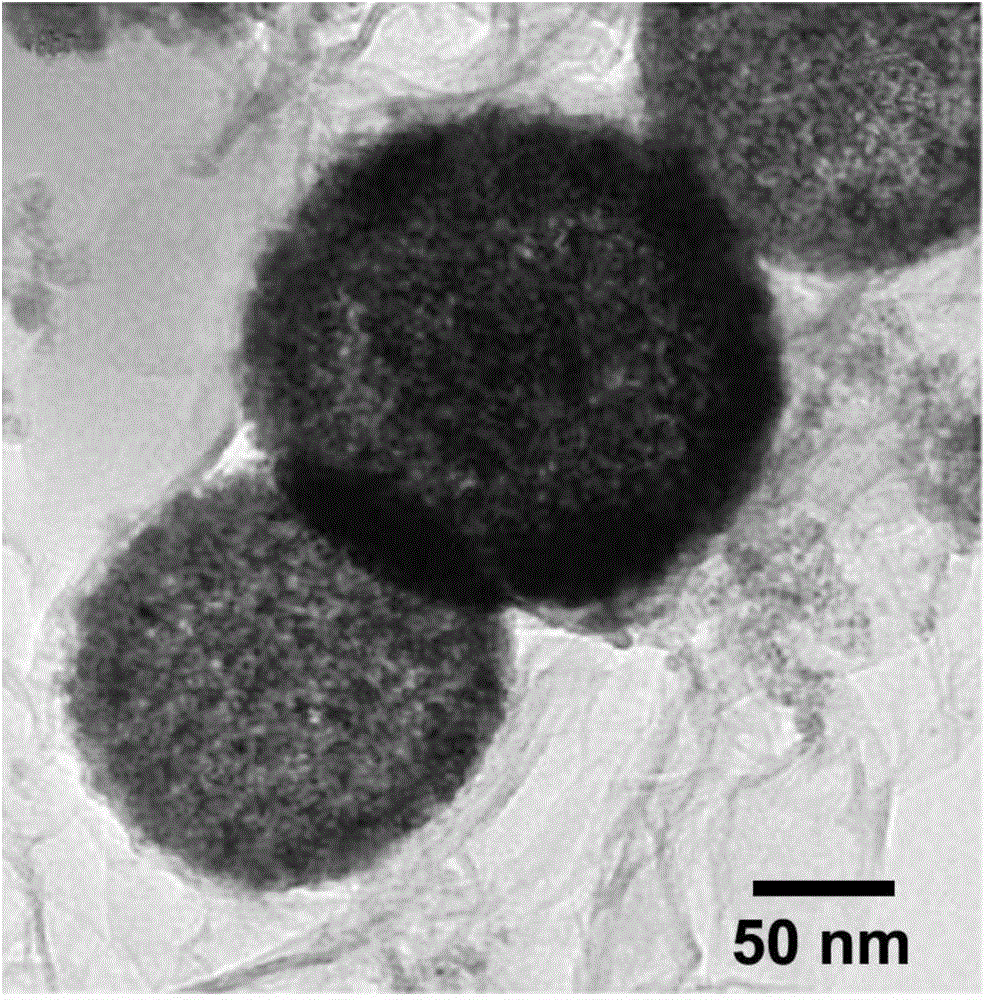

[0034] (3) Transfer the mixed solution of step (2) into a high-pressure reactor, place it in an oven and heat it at 150°C for 24 hours. After the reaction, the product obtained is washed 5 times with deionized water to obtain a graphene oxide-based hollow dioxide tin composite materials;

[0035] (4) Disperse the graphene oxide-based hollow tin dioxide composite material in step ...

Embodiment 2

[0041] A preparation method of a graphene-based hollow tin dioxide lithium-ion battery negative electrode material, the steps are as follows:

[0042] (1) Add 0.6 parts by weight of graphene oxide to a mixed solvent composed of 1000 parts by weight of ethanol and 1800 parts by weight of deionized water, and ultrasonically vibrate for 10 minutes to obtain a stable graphene oxide dispersion;

[0043] (2) Add 15 parts by weight of sodium stannate trihydrate in the graphene oxide dispersion of step (1), after stirring for 3min, add 20 parts by weight of urea, and continue stirring for 5min;

[0044] (3) Transfer the mixed solution of step (2) into a high-pressure reactor, place it in an oven and heat it at 180°C for 24 hours. After the reaction, the product obtained is washed 5 times with deionized water to obtain a graphene oxide-based hollow dioxide tin composite materials;

[0045] (4) Disperse the graphene oxide-based hollow tin dioxide composite material of step (3) in 100 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com