Industrial automated transfer mechanism

A technology of automatic transmission and mechanical device, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of difficult and accurate transmission, waste of manpower in manual transmission, and grasping of mechanical parts, etc., to facilitate wireless remote control operation and save labor time. , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

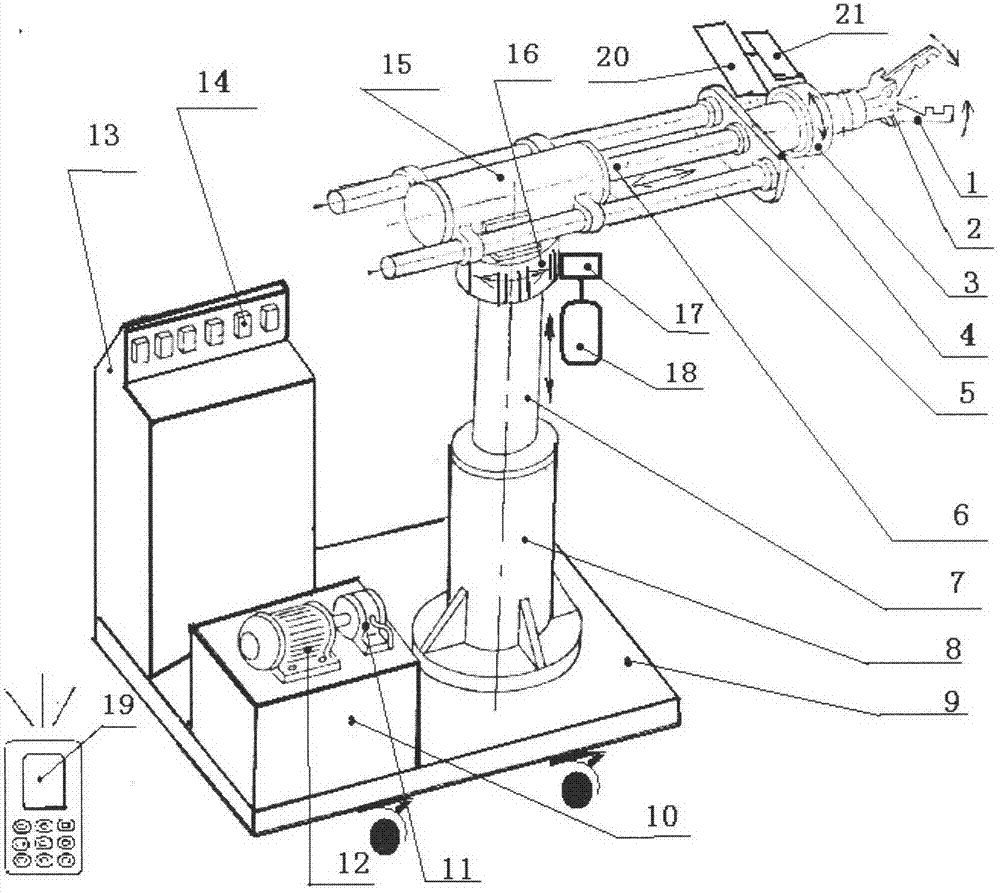

[0021] Such as figure 1 As shown, when a certain mechanical part is to be grasped or transmitted, the keyboard of the remote controller 19 is pressed, and the servo motor A18 and the servo motor B21 are respectively driven to drive the pinion A17 and the pinion B20 according to the spatial position of the mechanical part, thereby Drive the rotating disk 16 and the wrist 3 to grab the mechanical part. If the position of the mechanical part is relatively low, you can also turn on the hydraulic transmission (the hydraulic transmission is not drawn) so that the column 7 descends along the column oil cylinder 8; The hydraulic system (hydraulic transmission is not shown) that can remotely control the arm telescopic cylinder 15 makes the piston rod 6 move horizontally along the arm telescopic cylinder 15. When the piston rod 6 retracts, the two hands grasp 1 and rotate around the hand grasp fulcrum 2 respectively. Mechanical parts; when the piston rod 6 stretched out, the mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com