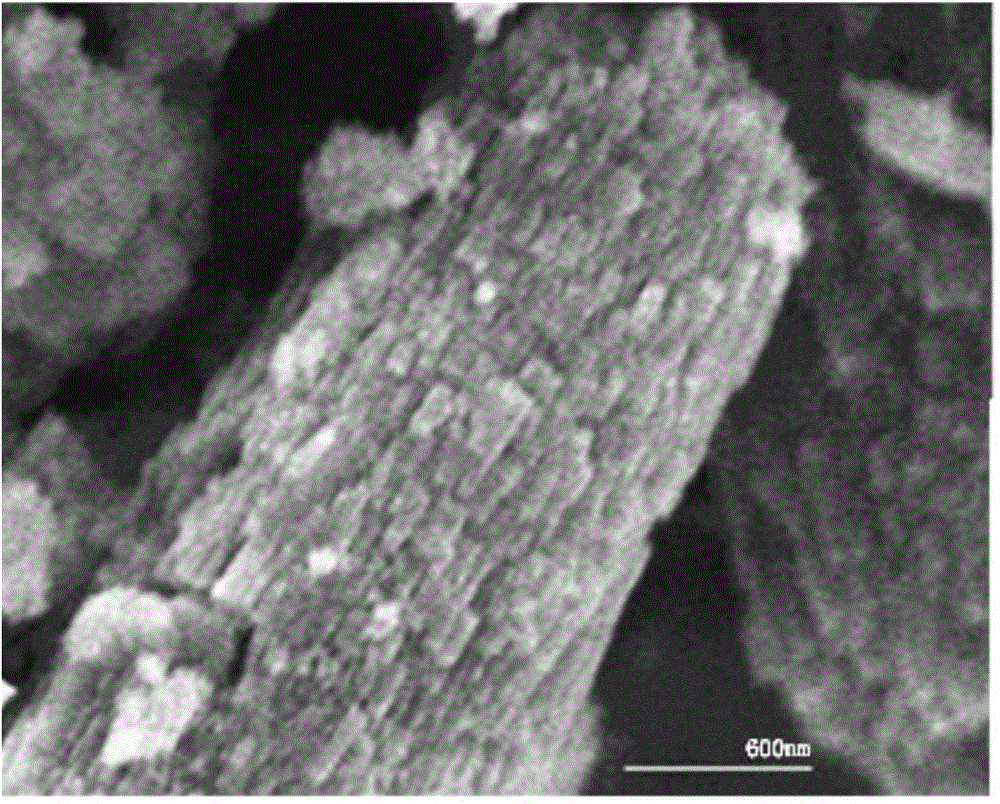

Method for ionothermal synthesis of SAPO-31 molecular sieve nanorod

A SAPO-31, ionothermal synthesis technology, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, nanotechnology and other directions, can solve the problems of large amount of solvent, difficult recycling and reuse, etc., to reduce waste liquid The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

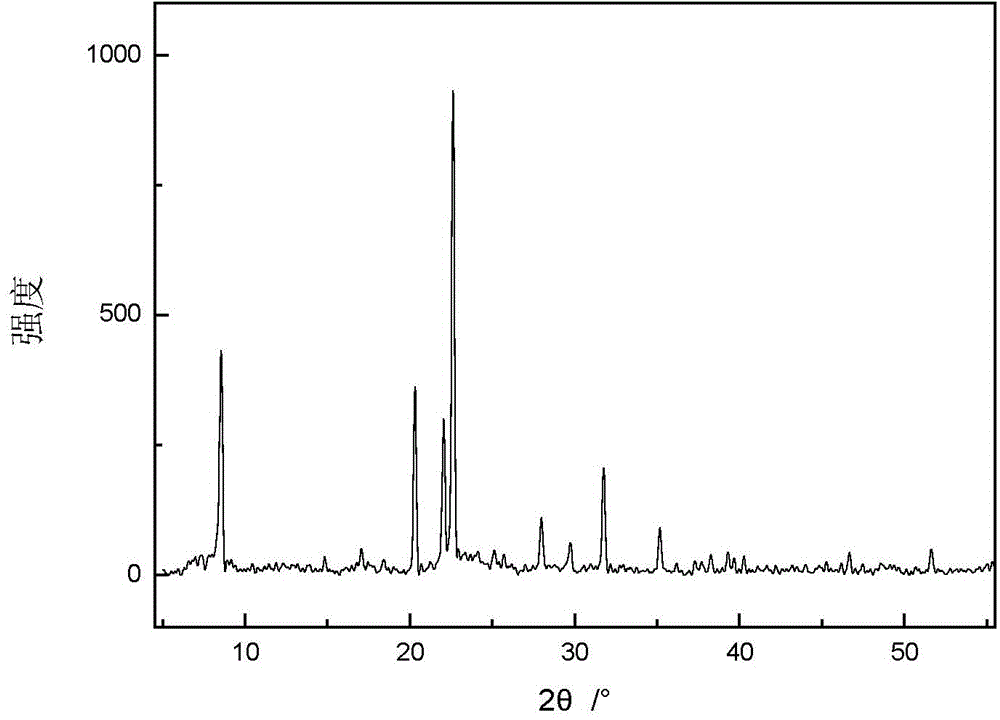

[0026] Specific embodiment one: the method of the method for ion thermal synthesis of SAPO-31 molecular sieve nanorods in this embodiment is as follows:

[0027] 1. Preparation of mixed gel:

[0028] a. Weigh the di-n-butylamine whose mass fraction is 95%, and decompose the gained Al 2 o 3 Aluminum isopropoxide with a mass fraction of 24.8% of aluminum isopropoxide, phosphoric acid with a mass fraction of 85%, SiO 2 25.9% silica sol and 1-ethyl-3-methylimidazole bromide;

[0029] b. Heat the 1-ethyl-3-methyl imidazole bromide weighed in step a to a molten state at 70-100°C;

[0030] c. Add the phosphoric acid with a mass fraction of 85% weighed in step a into the molten 1-ethyl-3-methyl imidazole bromide, and stir at a speed of 400-600r / min for 5-15min to obtain mixture A;

[0031] d, aluminum isopropoxide, SiO taken by weighing in step a 2 Silica sol with a content of 25.9% and di-n-butylamine were sequentially added to the mixture A, and stirred at a speed of 1000-1200...

specific Embodiment approach 2

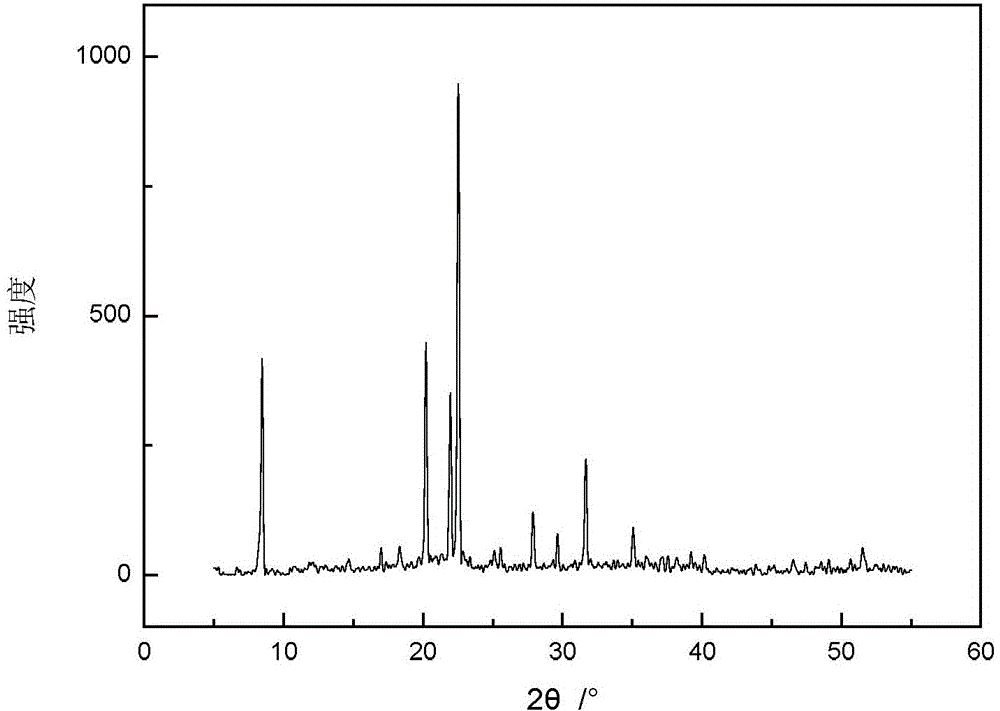

[0038] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the silicon source described in step 1 uses SiO 2 The silicon aerosol content is 100%, and the mass ratio of phosphoric acid to silicon aerosol is 1:(0.04-0.16). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 2 in that in step 2, crystallization is carried out at a temperature of 180-185° C. for 48-50 hours. Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com