Method for accelerating crystallization of isotactic poly 1-butylene by shear flow

A technology of shear flow and butene, applied in the field of polymer crystallization kinetics, can solve problems affecting industrial applications, slow crystal growth rate, and small number of nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Raise the temperature of the flat vulcanizer to 170°C, keep the pressure at 20bar for 5 minutes, and press the poly-1-butene particles into a sample of a certain thickness;

[0025] 2. Place the laminated poly-1-butene sheet in the shear cell, and heat it to the heat treatment temperature of 200°C at a rate of 30°C / min;

[0026] 3. Adjust the height of the shear cell so that the sample reaches a predetermined thickness of 10um; at the same time, keep the sample at the heat treatment temperature for 5 minutes to eliminate its thermal history;

[0027] 4. Lower the temperature to the crystallization temperature of 85°C at a rate of 30°C / min;

[0028] 5. Keep at the crystallization temperature for a sufficient time to completely crystallize the sample.

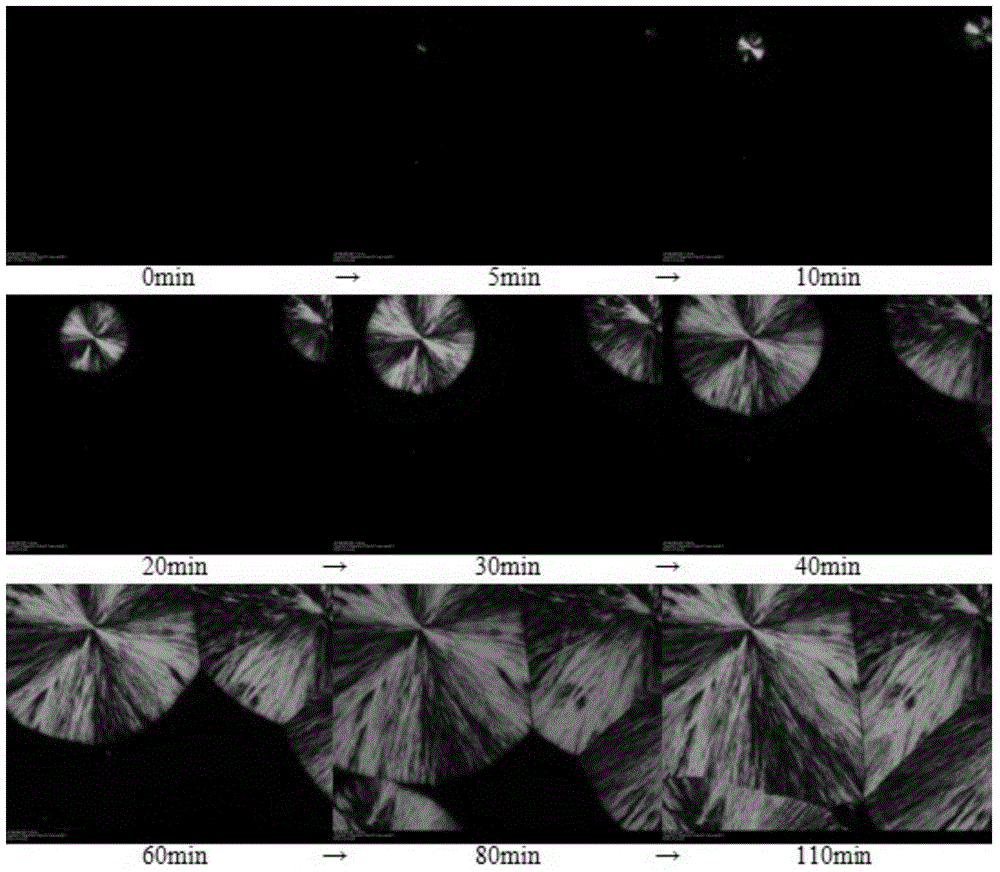

[0029] as attached figure 1 As shown, under the condition of static isothermal crystallization, only spherulites are formed, and the number of spherulites is small and the size is large.

Embodiment 2

[0031] 1. Put the laminar poly-1-butene laminated film with a flat vulcanization mechanism in Example 1 in the shearing cell, and heat it to a heat treatment temperature of 200° C. at a rate of 30° C. / min;

[0032] 2. Adjust the gap value of the shear cell so that the sample reaches a predetermined thickness of 10um; at the same time, keep the sample at the heat treatment temperature for 5 minutes to eliminate its thermal history;

[0033] 3. Lower the temperature to the crystallization temperature of 85°C at a rate of 30°C / min;

[0034] 4. Immediately after the temperature drops to the crystallization temperature, a shear flow field is applied to the sample, the shear rate is 10s-1, and the shear time is 5s;

[0035] 5. Keep at the crystallization temperature for a sufficient time to completely crystallize the sample.

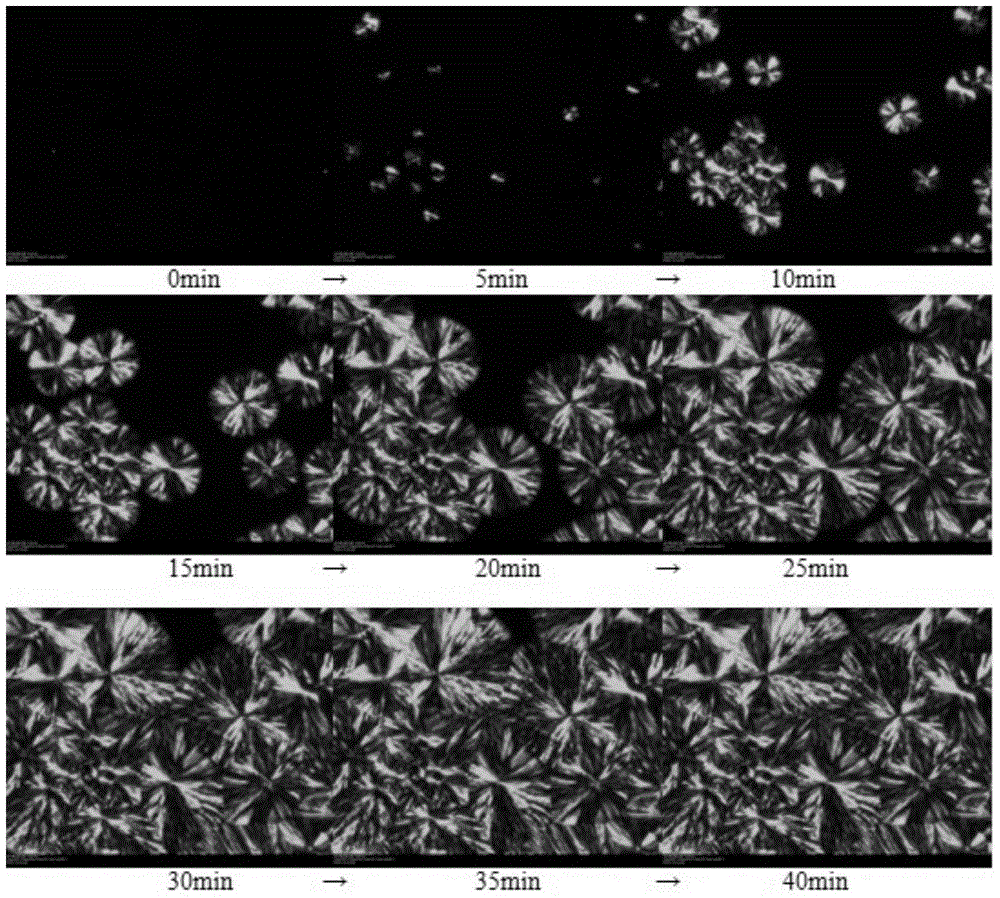

[0036] as attached figure 2 As shown, when the shear rate is 10-1s, the number of spherulites increases, and the time for the crystals to cover the field o...

Embodiment 3

[0038] 1. Put the laminar poly-1-butene laminated film with a flat vulcanization mechanism in Example 1 in the shearing cell, and heat it to a heat treatment temperature of 200° C. at a rate of 30° C. / min;

[0039] 2. Adjust the gap value of the shear cell so that the sample reaches a predetermined thickness of 10um; at the same time, keep the sample at the heat treatment temperature for 5 minutes to eliminate its thermal history;

[0040] 3. Lower the temperature to the crystallization temperature of 85°C at a rate of 30°C / min;

[0041] 4. Immediately after the temperature drops to the crystallization temperature, a shear flow field is applied to the sample, the shear rate is 20s-1, and the shear time is 5s;

[0042] 5. Keep at the crystallization temperature for a sufficient time to completely crystallize the sample.

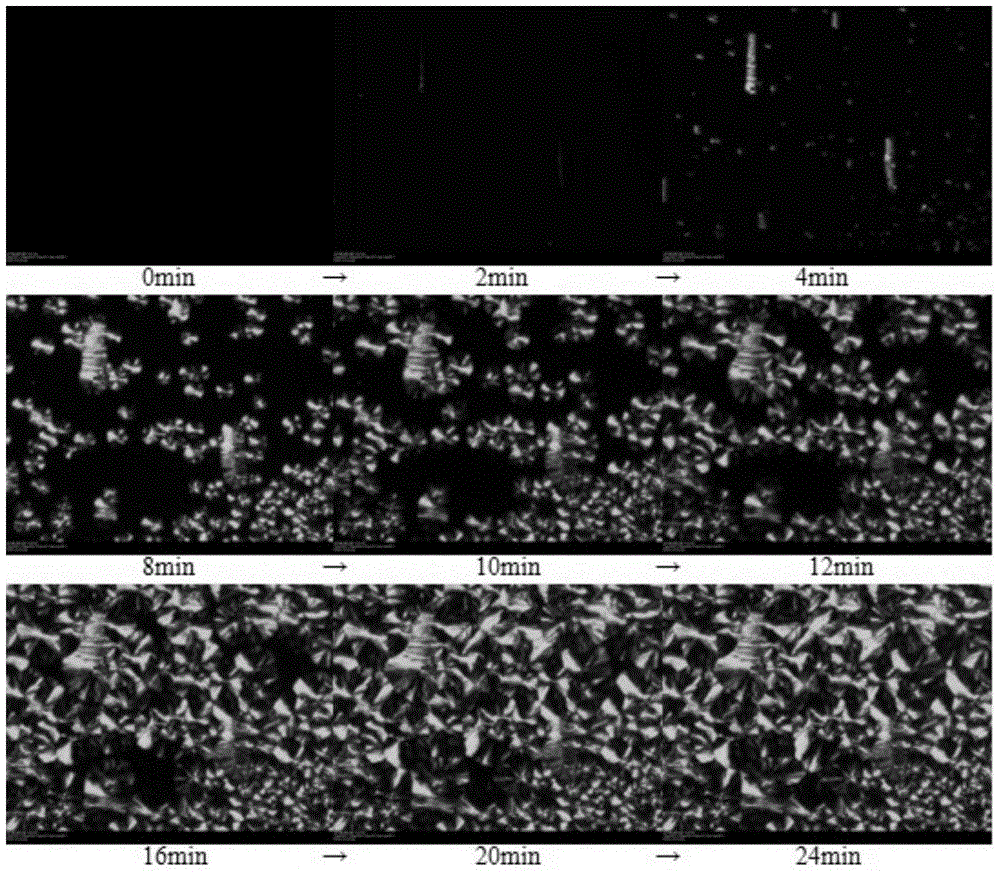

[0043] as attached image 3 As shown, when the shear rate is 20-1s, the system first forms columnar crystals and then spherulites. Compared with Example 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com