Coating composition for brightness enhancement film with high refraction rate

A high-refractive index and composition technology, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problem that the wear resistance and weather resistance of brightening coatings do not meet the requirements of process use, and adjust the beam convergence angle. Not good enough, poor mold release, etc., to achieve the effect of improving light source utilization, good coating brightness, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

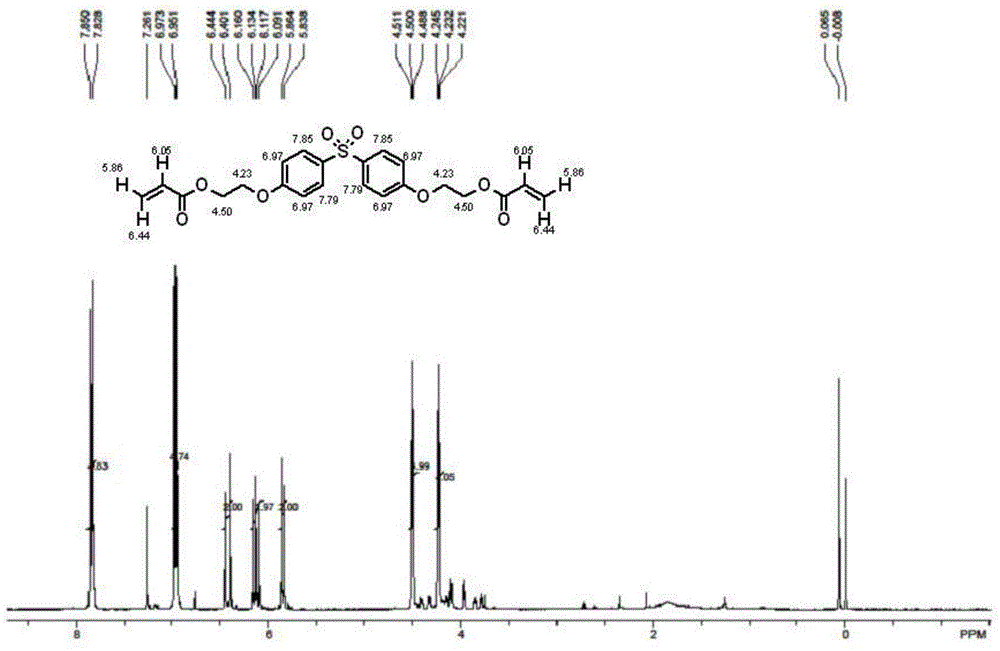

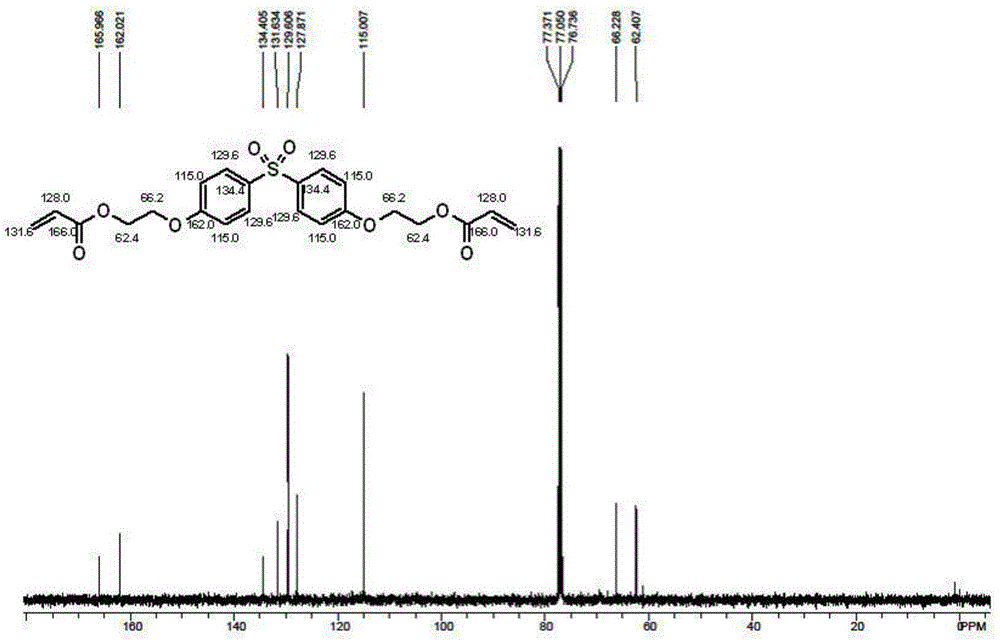

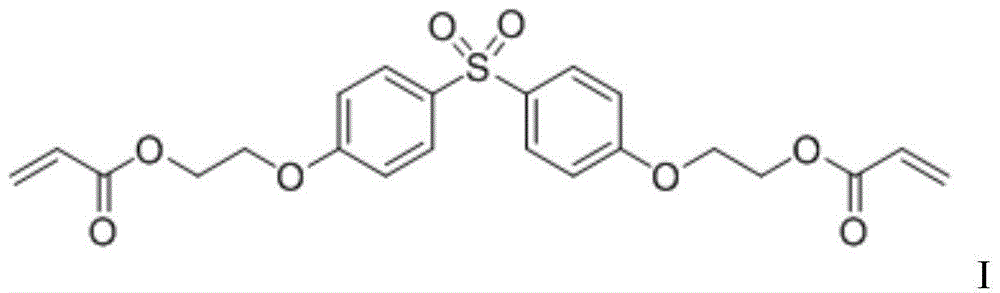

Image

Examples

Embodiment 1

[0040] After batching according to the formula in Table 1, mix each raw material, stir thoroughly for 2 hours to disperse each component evenly, and then filter.

Embodiment 2

[0042] After batching according to the formula in Table 1, mix the raw materials, stir thoroughly for 2.2 hours to disperse the components evenly, and then filter.

Embodiment 3

[0044] After batching according to the formula in Table 1, mix the raw materials, stir thoroughly for 2.5 hours to disperse the components evenly, and then filter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com