Water-based shower-coated super matte toning finishing coat

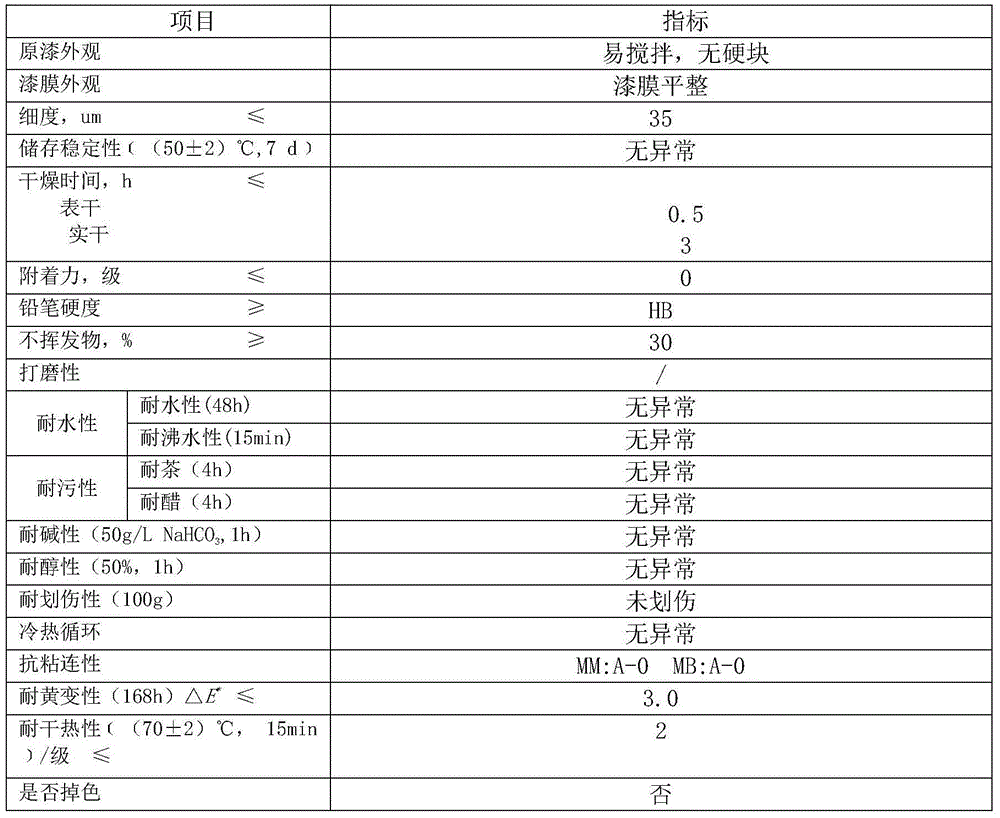

A flow coating, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as uneven gloss, difficult matting, and bright spots, and achieve good hand feeling, good adhesion, and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take water-based acrylic resin: 44 kg, water-based polyurethane modified acrylic resin: 18 kg, defoamer: 0.1 kg, matting agent: 5 kg, film-forming aid: 7 kg, wetting agent: 0.8 kg, dispersant: 0.4 kg, thickener: 0.5 kg, water: 24.2 kg.

[0027] First add water-based acrylic resin and water-based polyurethane modified acrylic resin dispersion into the dispersion tank, then add defoamer, matting agent, film-forming aid, wetting agent and dispersant under medium-speed stirring, and wash the tank with water wall and rotating shaft, and then disperse at high speed for about 30 minutes until the fineness is less than 35um, and finally add thickener under medium-speed stirring state, and pack 100 kg of the product of the present invention after stirring evenly.

[0028] First paint 2-3 times of water-based single or two-component water-based wood paint on the wood, or 2-3 times of PU paint or oily UV paint, the specific number of times can be determined according to the desire...

Embodiment 2

[0030] Take water-based acrylic resin: 36 kg, water-based polyurethane modified acrylic resin: 25 kg, defoamer: 0.2 kg, matting agent: 5 kg, film-forming aid: 7 kg, water: 24.2 kg, wetting agent: 0.1, Dispersant: 1.2 kg, thickener: 0.5 kg.

[0031] First add water-based acrylic resin and water-based polyurethane modified acrylic resin dispersion into the dispersion tank, then add defoamer, matting agent, film-forming aid, wetting agent and dispersant under medium-speed stirring, and wash the tank with water wall and rotating shaft, and then disperse at high speed for about 30 minutes until the fineness is less than 35um, and finally add thickener under medium-speed stirring state, and pack 100 kg of the product of the present invention after stirring evenly.

[0032] First paint 2-3 times of water-based single or two-component water-based wood paint on the wood, or 2-3 times of PU paint or oily UV paint, the specific number of times can be determined according to the desired e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com