Phosphoaluminate cement paste for deep sea cementing and shallow flow disaster prevention

A deepwater cementing and cement slurry technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult hole cleaning, long thickening conversion time, difficult solidification, etc., to prevent shallow flow disasters , adjustable thickening time, short thickening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

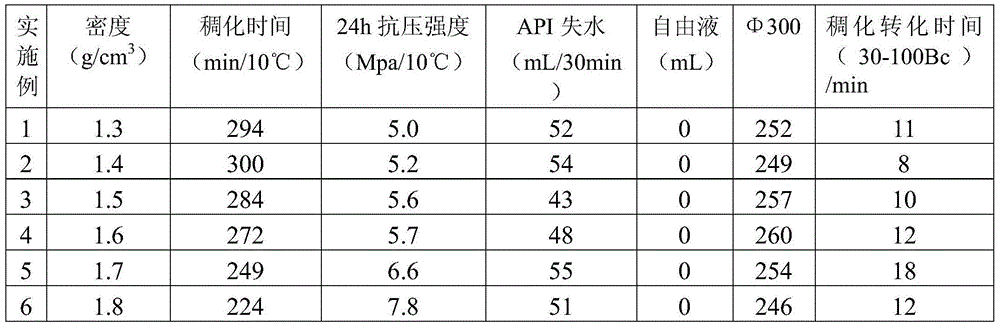

Examples

Embodiment 1

[0054] Example 1. Preparation of cement slurry for controlling shallow laminar flow disasters in deepwater well cementing

[0055] Weigh each component according to the following formula:

[0056] 100kg of reconciled cement, 75kg of seawater, 0.2kg of silicone oil defoamer CX66L, acrylamide-2-acrylamide-2-methylpropanesulfonic acid copolymer (the number average molecular weight is 9×10 5 g / mol) 4kg, lithium chloride 1.5kg, boric acid 0.5kg, hollow glass microspheres (density 0.44g / cm 3 )35kg.

[0057] Preparation method: pre-mix the required solid materials evenly for use, then mix the liquid materials evenly, add the pre-mixed solid materials, and stir evenly to obtain the cement slurry for controlling shallow laminar flow hazards.

Embodiment 2

[0058] Example 2. Preparation of cement slurry for controlling shallow laminar flow disasters in deepwater well cementing

[0059] Weigh each component according to the following formula:

[0060]100kg of reconciled cement, 65kg of seawater, 0.2kg of silicone oil defoamer CX66L, acrylamide-2-acrylamide-2-methylpropanesulfonic acid copolymer (the number average molecular weight is 9×10 5 g / mol) 4kg, lithium chloride 1.5kg, boric acid 0.5kg, hollow glass microspheres (density 0.44g / cm 3 ) 31kg.

[0061] Preparation method: pre-mix the required solid materials evenly for use, then mix the liquid materials evenly, add the pre-mixed solid materials, and stir evenly to obtain the cement slurry for controlling shallow laminar flow hazards.

Embodiment 3

[0062] Example 3. Preparation of cement slurry for controlling shallow laminar flow disasters in deepwater well cementing

[0063] Weigh each component according to the following formula:

[0064] 100kg of reconciled cement, 58kg of seawater, 0.2kg of silicone oil defoamer CX66L, acrylamide-2-acrylamide-2-methylpropanesulfonic acid copolymer (the number average molecular weight is 9×10 5 g / mol) 4kg, lithium chloride 1.5kg, boric acid 0.5kg, hollow glass microspheres (density 0.44g / cm 3 ) 20kg.

[0065] Preparation method: pre-mix the required solid materials evenly for use, then mix the liquid materials evenly, add the pre-mixed solid materials, and stir evenly to obtain the cement slurry for controlling shallow laminar flow hazards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com