Induced sphingomonas paucimobilis as well as preparation method and application of induced sphingomonas paucimobilis

A technology of monosporus and sphingolipids, which is applied in the field of cold gellan gum preparation, can solve the problems of restricting gellan gum production, application and development, difficult to improve product indicators, and lower gel yield, and achieve high viscosity, high gel yield, and high gel yield. The effect of high mutagenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

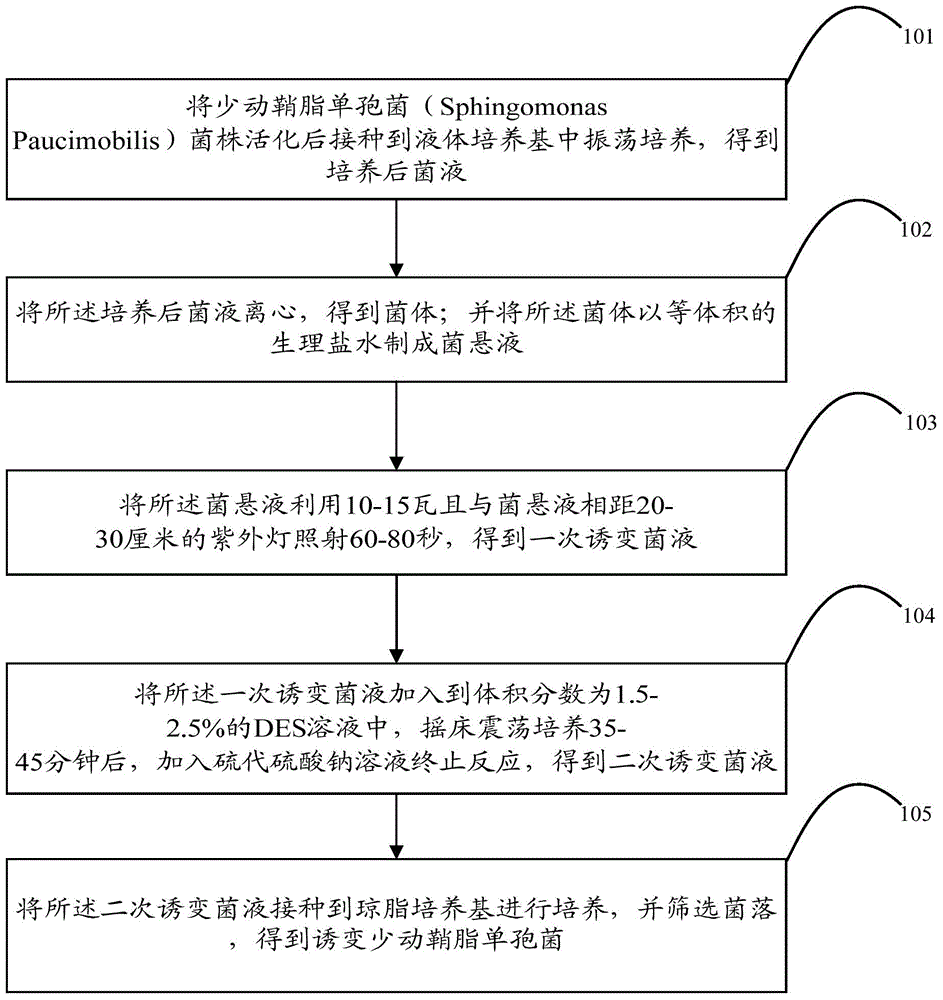

[0032] Please refer to figure 1 , the preparation method of this mutagenic Sphingomonas pauciformis provided by the invention comprises the following steps:

[0033] Step 101: Inoculate the activated Sphingomonas Paucimobilis strain into a liquid medium for shaking culture to obtain cultured bacterial liquid;

[0034] After activation, Sphingomonas pauciformis is inoculated into a liquid medium for cultivation to ensure that the bacteria can proliferate in large quantities and prepare for subsequent mutagenesis.

[0035] Step 102: centrifuging the cultured bacterial liquid to obtain bacterial cells; and preparing bacterial suspensions from the bacterial cells with an equal volume of physiological saline;

[0036] Using the bacterial liquid cultured in the liquid medium, the bacterial cells are collected by centrifugation, and then the bacterial cells are made into a bacterial suspension with an equal volume of normal saline. Bacteria cells rupture, so that the bacteria from ...

Embodiment 1

[0050] S11: Transfer the Sphingomonas Paucimobilis strain to the activated slant and culture it at a constant temperature of 30°C for 24 hours, then transfer it to a liquid medium, and cultivate it at 30°C at a speed of 200 rpm for 18 hours , to obtain the cultured bacterial liquid;

[0051] S12: Centrifuge the cultured bacterial solution at 4000 rpm for 20 minutes to obtain bacterial cells; add an equal volume of physiological saline to the bacterial cells to prepare a bacterial suspension;

[0052] S13: irradiating the bacterial suspension with a 15-watt ultraviolet lamp 20 cm away from the bacterial suspension for 60 seconds to obtain a mutagenic bacterial liquid;

[0053] S14: adding the primary mutagenizing bacteria solution into a DES solution with a volume fraction of 2%, and incubating on a shaking table for 40 minutes, adding sodium thiosulfate solution to terminate the reaction, and obtaining a secondary mutagenizing bacteria solution;

[0054] Wherein, in this step...

Embodiment 2

[0057] S21: Transfer the Sphingomonas Paucimobilis strain to the activated slant and culture it at a constant temperature of 30°C for 24 hours, then transfer it to a liquid medium, and cultivate it at 30°C at a speed of 200 rpm for 18 hours , to obtain the cultured bacterial liquid;

[0058] S22: Centrifuge the cultured bacterial solution at 4000 rpm for 20 minutes to obtain bacterial cells; add an equal volume of physiological saline to the bacterial cells to prepare a bacterial suspension;

[0059] S23: irradiating the bacterial suspension with a 15-watt ultraviolet lamp 25 cm away from the bacterial suspension for 70 seconds to obtain a mutagenic bacterial liquid;

[0060] S24: adding the primary mutagenizing bacteria solution into a DES solution with a volume fraction of 2%, and incubating on a shaking table for 40 minutes, adding sodium thiosulfate solution to terminate the reaction, and obtaining a secondary mutagenizing bacteria solution;

[0061] Wherein, in this step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com