Energy-saving setting machine

A technology of setting machine and waste heat recovery device, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of increasing power consumption, increasing air volume, heat waste, etc. Guarantee the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

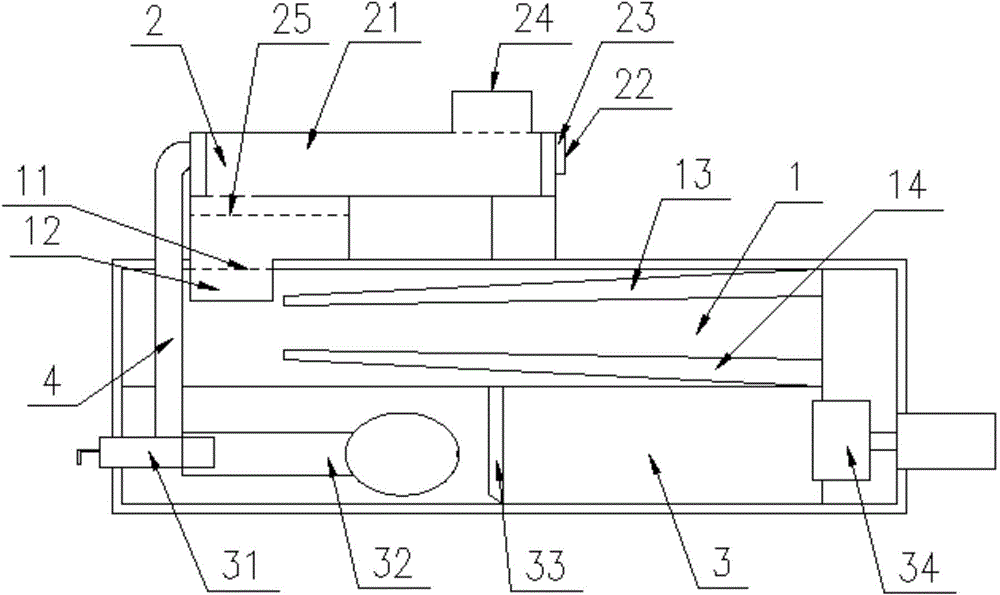

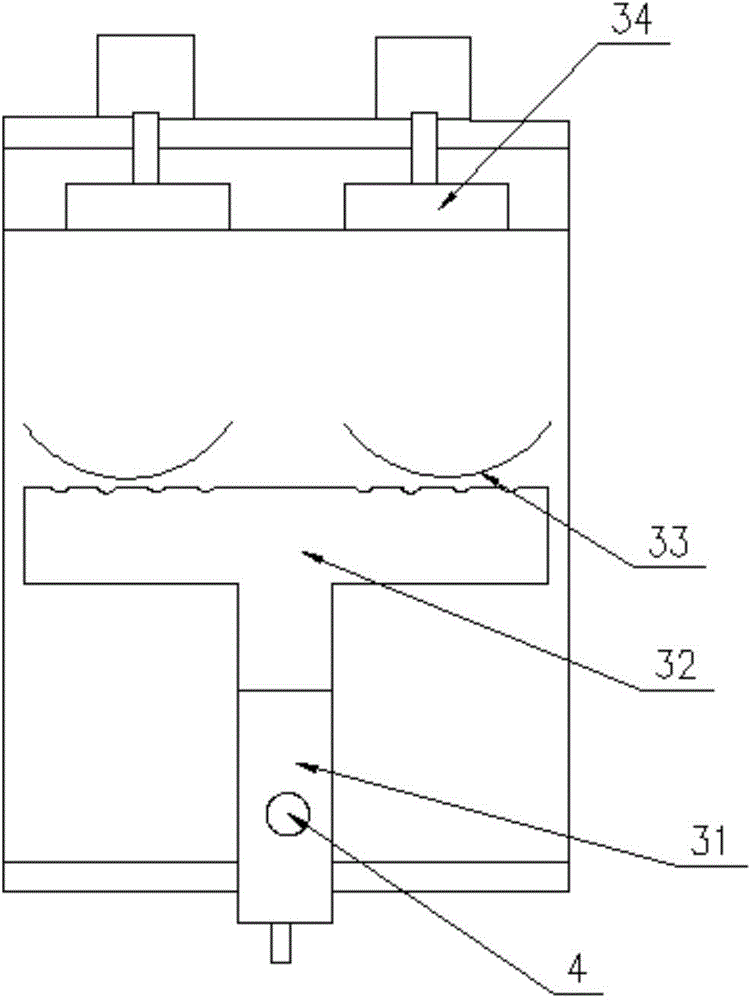

[0015] Such as figure 1 and figure 2 As shown, the energy-saving setting machine includes an oven 1, a heat supply device 3 and a waste heat recovery device 2. The waste heat recovery device 2 includes a heat exchanger 21, and the heat exchanger 21 adopts a differential type exchanger. The patent number is ZL201320416519.9 . The heat exchanger 21 is connected to the waste gas discharge port 24 in the waste heat recovery device 2 and the air supply port 22 provided with the blower 23, and is also connected to the waste discharge port 11 of the oven 1, and is connected to the heat supply device 3 through the waste heat recovery pressure air pipe 4. connection; the waste gas discharge port 24 in the waste heat recovery device 2 communicates with the waste discharge port 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com