Light roof system

A roofing system and lightweight technology, applied in the direction of roof covering, building roof, roof insulation materials, etc., can solve problems such as increasing building load, and achieve the effect of reducing building load, improving comfort, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

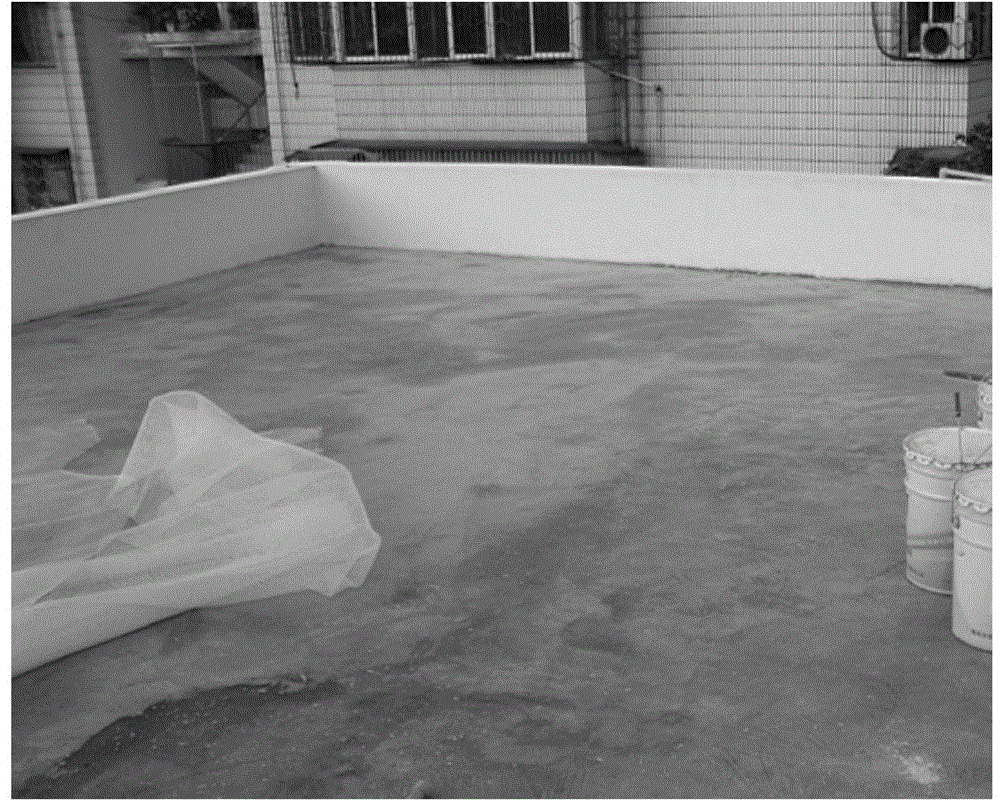

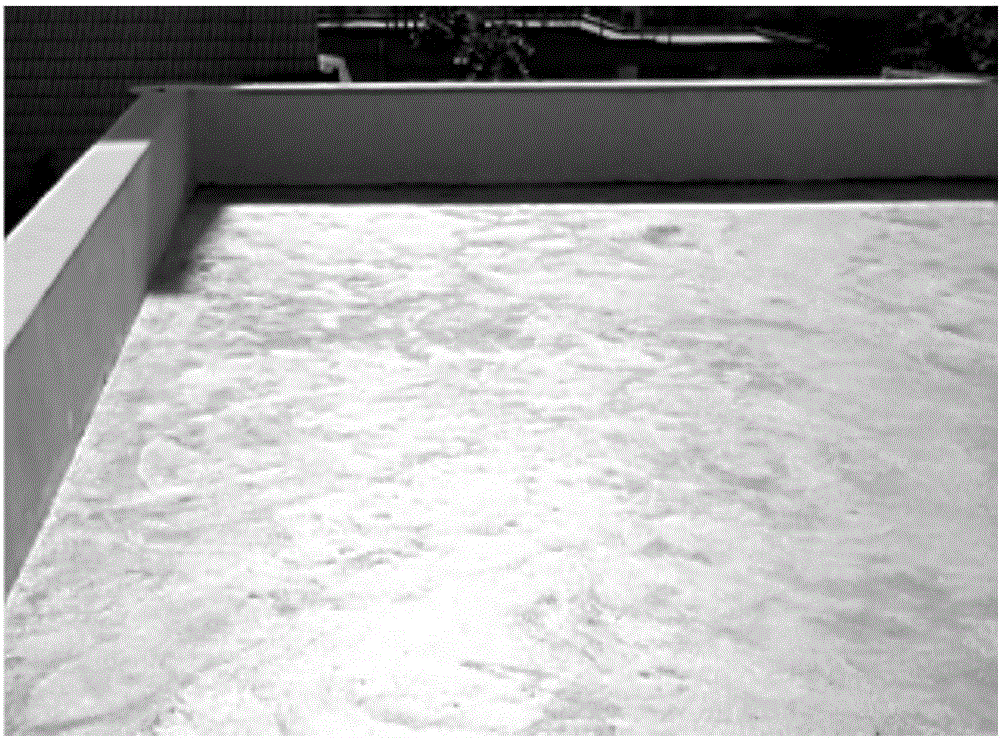

[0093] Dalong Villa on Xike Road, Haikou was refurbished and rebuilt in March 2014. The structure diagram of the villa is shown in image 3 . The villa has 4 floors, and the area of the 4th floor is about half of that of the 3rd floor. The terrace of the room on the 4th floor is the roof of the 3rd floor, and the roofing method on the floor tile protection layer of the "Central South Region Engineering Construction Standard Design Architectural Atlas" is adopted, and the light roof system provided by the present invention is arranged on the 4th floor roof.

[0094] The specific method of roofing on the third floor is as follows: set a 20mm thick (thinnest) 1:8 cement hydrophobic expanded perlite on the reinforced concrete roof slab to find a 2% slope, and a 20mm 1:2.5 cement mortar Leveling, 1 layer of 1.5mm waterproof coating, 1 layer of 1.2mm polymer waterproof membrane, a full layer of 0.3mm thick polyethylene film, 25mm thick 1:4 dry hard cement mortar, 8mm-10mm floor ...

Embodiment 2

[0100] A three-story self-built house in Danzhou, Hainan. The original roof was made of cast-in-place concrete slabs, and the roof was not waterproofed. The roof surface was leveled and sloped with a layer of 1:2.5 cement mortar with an average thickness of 20mm. After 2 years of use, the roof cement mortar cracked severely in many places, resulting in serious roof leakage. In summer, the solar radiation is strong, the highest temperature on the roof is above 52°C, and the indoor ceiling temperature of the downstairs house can reach as high as 45°C. Due to the severe radiant heat from the ceiling, the thermal comfort of the indoor environment is still poor even if the air conditioner is installed indoors. Generally, the air conditioner will not be effective until the ceiling cools down after 12 o'clock every night.

[0101] In August 2013, the self-built house adopts the light-duty roof system provided by the present invention: clean up the original slope-leveling layer; apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com