Balancing weight for wind-power blade

A technology of wind turbine blades and counterweights, which is applied in wind power generation, wind turbine components, wind engines, etc., can solve the problems of increased weight, metal corrosion, complicated process, etc., to improve the bonding performance, increase the overall density, The effect of increasing the bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in conjunction with accompanying drawing and specific embodiment:

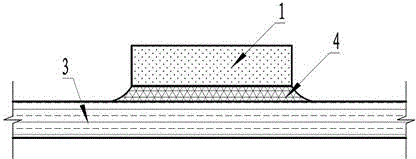

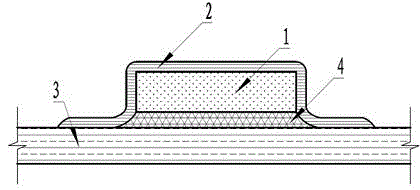

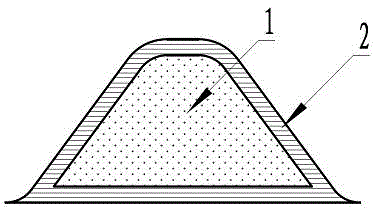

[0020] Such as image 3 As shown, a counterweight for wind power blades, the counterweight is a prefabricated composite material counterweight; the inside of the counterweight uses high-density metal or high-density rubber as the inner core 1, and the counterweight The outside of the weight block is made of fiber-reinforced resin composite material, and the fiber-reinforced resin composite material is formed by vacuum infusion molding or hand lay-up molding as the outer layer 2 of the outer protective layer and adhesive layer; the outer layer 2 is made of high-density metal or high-density rubber. The inner core 1 is used to make the weight of the counterweight reach the weight of the counterweight required by the blade shell; the fiber-reinforced resin composite material is used as the outer protective layer to prevent the inner core from being corroded in the environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com