A high-precision roll angle measurement method and device for optical drift compensation of all optical paths

A technology for roll angle measurement and light measurement, which is applied in the field of optical measurement, can solve problems such as the inability to eliminate the influence of angle drift, limit measurement accuracy, and difficulty in parallel adjustment of double beams, so as to improve measurement resolution, compact optical structure, and facilitate on-site measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings.

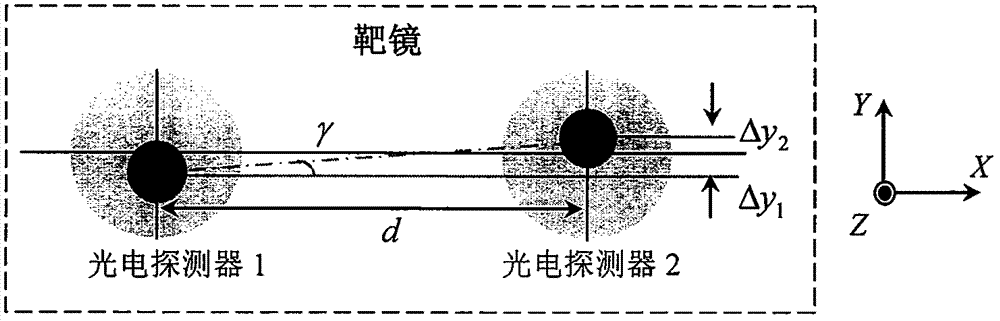

[0028] The roll angle measurement of the present invention is based on the parallel double beam combined measurement method. The measurement principle of the parallel double beam method is as follows figure 1 As shown, two parallel light beams with a distance of d in the x-axis direction are respectively perpendicularly incident on the two photodetectors fixed on the target mirror (moving unit) along the z-axis direction. When the target mirror rolls around the z-axis (parallel to the direction of the collimated beam) with a γ angle, the position of the beam on the photodetector changes accordingly. Suppose the y-axis displacement of the two beams of light on the detector is Δy 1 And Δy 2 , By the geometric relationship, the roll angle can be approximately expressed as

[0029] γ≈(Δy 2 -Δy 1 ) / d (1)

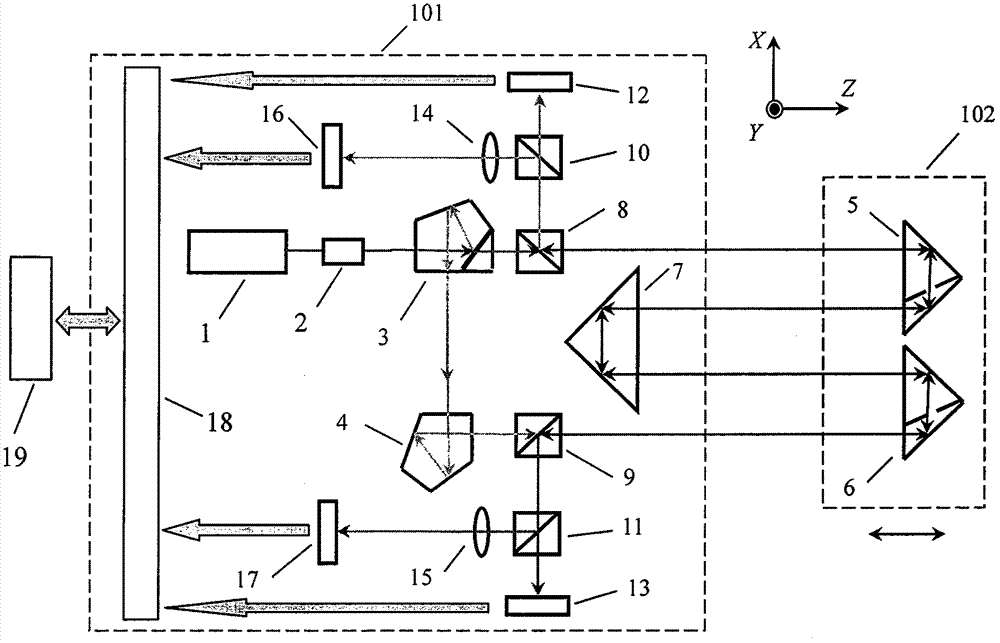

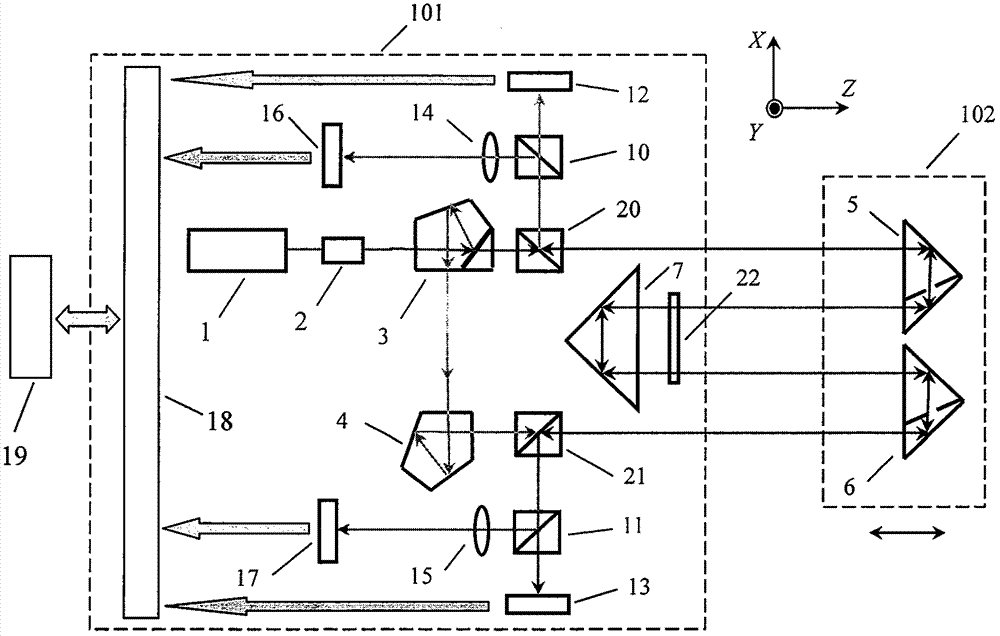

[0030] The measurement principle and optical path structure design adopted by the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com