Piezoresistive pressure meter chip structure and preparation method thereof

A technology of chip structure and pressure gauge, which is applied in the direction of fluid pressure measurement, measuring force, and instrumentation by changing the ohmic resistance, can solve the problems of limiting the application of piezoresistive pressure sensors, the chip cannot be thinned, and the chip is small, so as to improve The effect of process yield, high penetration rate, and small total thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below through specific embodiments and accompanying drawings. As shown in Figure 1, the specific manufacturing process of the new piezoresistive pressure sensor chip structure using anodic bonding and silicon wafer thinning process is:

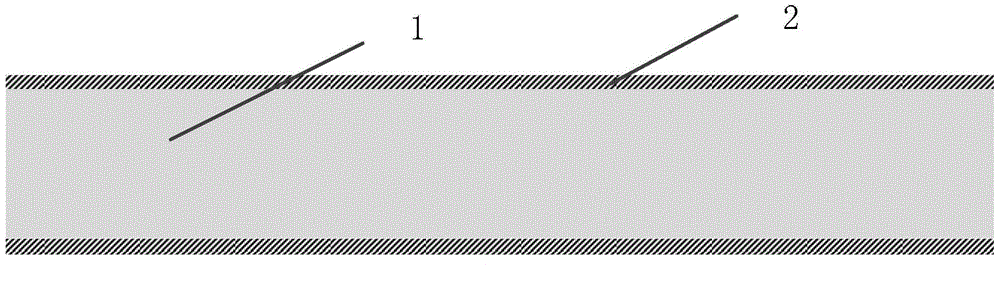

[0047] a) Preparation: the monocrystalline silicon substrate is used as the substrate 1 of the chip, the thickness of the substrate is 400 μm, there is silicon oxide 2 on the surface of the substrate, and the thickness of the silicon oxide is As shown in Figure 1(a);

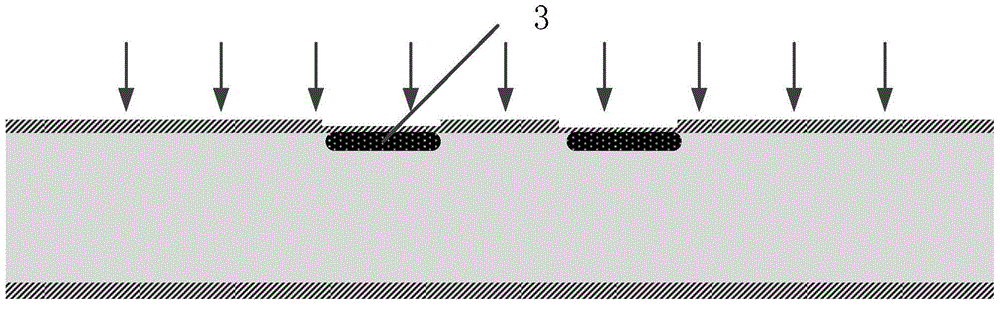

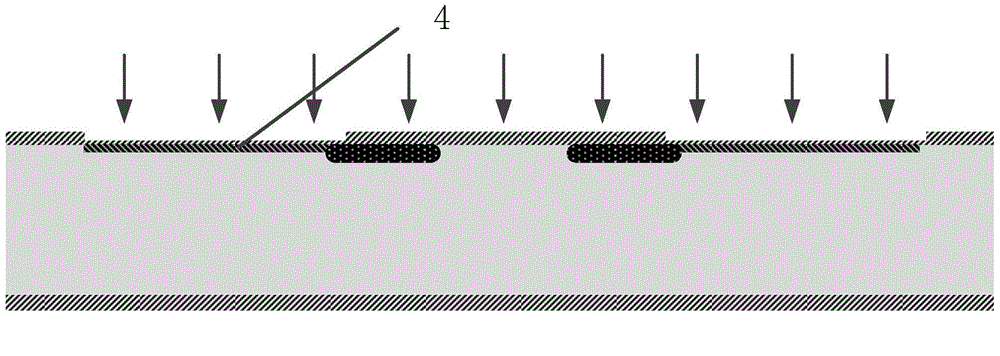

[0048] b) The piezoresistor 3 and the heavily doped contact region 4 are manufactured on the silicon wafer by standard piezoresistive technology, as shown in Figure 1(b) and (c), including: photolithographic light boron region; Corrosion) SiO 2 Ion implantation B + ; boron advancement; lithographic boron-enriched region, RIE SiO 2 ; ion implantation B + ; boron propulsion;

[0049] c) Make lead holes (ie contact hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com