Mirror support structure for a heliostat

A bracket structure and reflector technology, applied in the field of solar power generation, can solve problems such as difficulty in precision adjustment, and achieve the effect of simple and convenient adjustment process, high precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

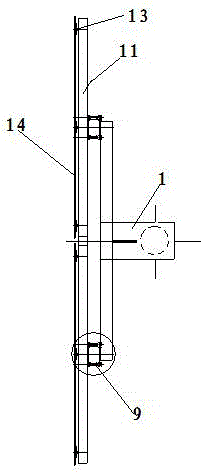

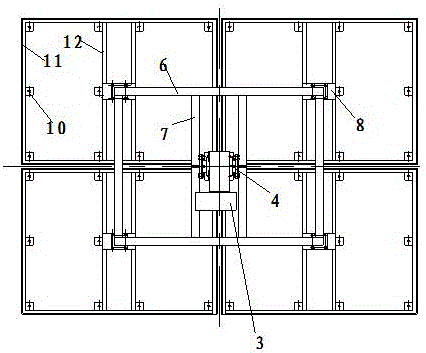

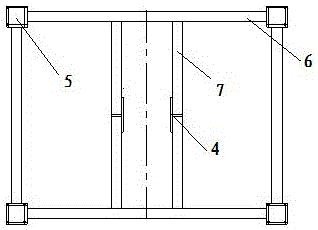

[0041] Main support 1 is welded into a main support rectangular frame by four main support peripheral rectangular tubes 6, and the middle part of the long side of this main support rectangular frame is welded with two main support middle rectangular tubes 7, each main support middle rectangular The middle part of the pipe 7 is welded with a transmission case connection steel plate 4, one end of the transmission case connection steel plate 4 is a straight edge and can be welded with the rectangular pipe 7 in the middle of the bracket, the other end is a semicircle, and there are 8 along the semicircle side. Circular and evenly distributed round holes are used for bolting through the bolts and the transmission box 3 of the heliostat. Therefore, the connecting steel plate 4 of the transmission box on the main bracket 1 is connected with the transmission box 3 for the heliostat by bolts, so that the main bracket 1 is fixed on the transmission box 3 of the heliostat.

[0042] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com