Hydrophobing dispersion gel having reduced active ingredient content, method for the production thereof, and use thereof for the hydrophobing of mineral materials

A dispersed and hydrophobic technology, applied in the direction of coating, etc., can solve the problem of damage to the surface

Inactive Publication Date: 2015-05-13

IONYS

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Dust or soot particles then deposit on these sticky films, which visually damage the surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0126]

[0127]

Embodiment 2

[0129]

Embodiment 3

[0131]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a hydrophobing dispersion gel having a reduced active ingredient content, comprising the following components in relation to a total amount of 100 wt%: (A) 0.1 - less than 50 wt% alkyl trialkoxysilane, (B) 0.1 - 1.0 wt% branched polyacrylic acid, (C) 0.5 - 2.0 wt% trialkyl amine n-oxide, (D) 3.0 - 10 wt% non-ionic surfactant, and (E) 10 - 80 wt% water. The invention further relates to a method for producing the hydrophobing dispersion gel and the use of the hydrophobing dispersion gel for the hydrophobing of mineral materials.

Description

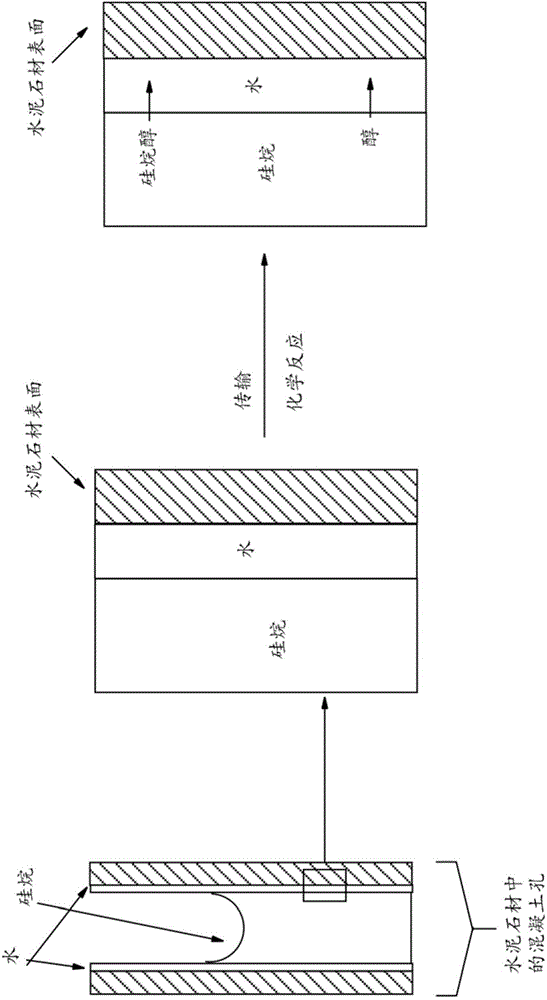

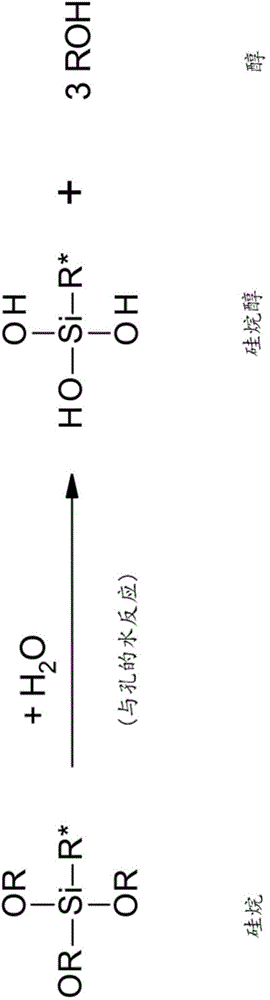

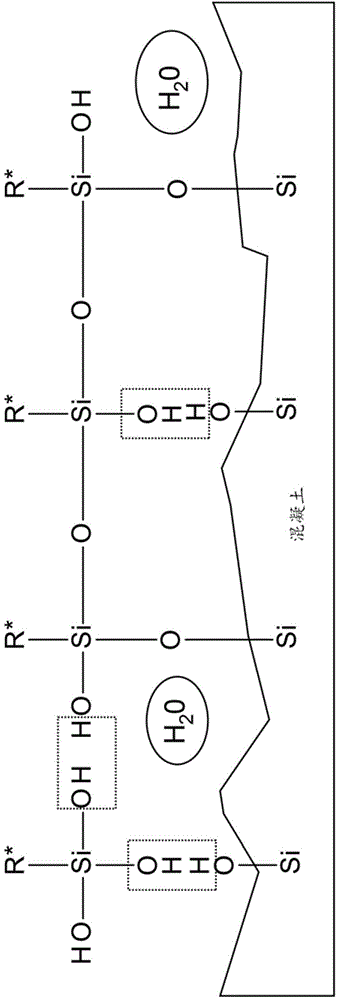

Technical field [0001] The present invention relates to a hydrophobic dispersion gel with a reduced active substance content and a method for producing the hydrophobic dispersion gel, and its use for hydrophobizing mineral materials. Background technique [0002] Cement stabilized materials, such as reinforced concrete seen in concrete buildings, are exposed to various environmental influences depending on their use. It is especially important for the functionality and durability of these materials, as well as for the components and buildings made from them, to resist the ingestion of saline solutions (such as deicing salts). Most of the commercially available deicing salt consists of table salt or rock salt, namely sodium chloride (NaCl). As a result of bringing the concrete components into contact with these aqueous chloride solutions, they are transported into the edge zone of the material by capillary suction. If chlorides reach the rebar, under certain conditions it may tr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B41/49

CPCC04B41/4922C08K5/101C08K5/175C08K5/20C08K5/32C08K5/5419C04B41/502C04B2103/406C09D133/02

Inventor 安德烈亚斯·格德斯德特勒夫·巴尔舒霍斯特·赛布特

Owner IONYS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com