Foamed separator splines for data communication cables

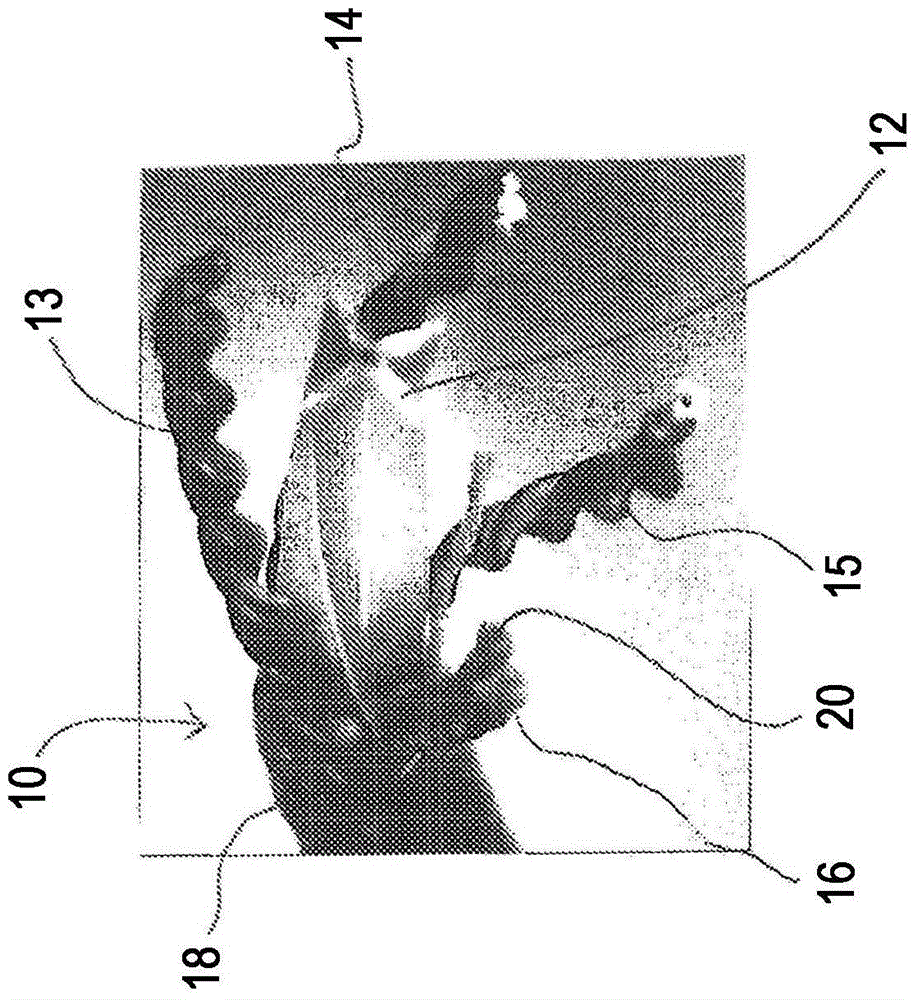

A technology for separating racks, communication cables, used in insulated cables, cables with double-stranded/quad-stranded, cables, etc., can solve problems such as fire and smoke hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

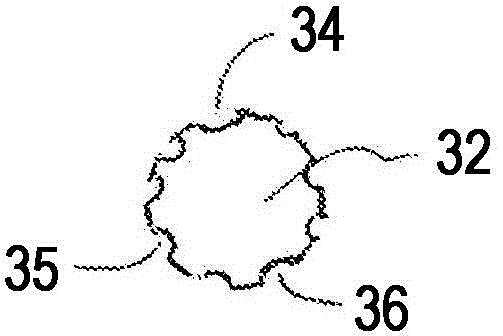

[0075] The purpose of these embodiments is to create extruded shapes from foamed polyetherimide (PEI) that can be used as split racks in cable construction.

[0076] Materials are shown in Table A.

[0077] Table A

[0078]

[0079]

[0080] Techniques and steps

[0081] Using a twin-screw extruder and standard polyetherimide compounding conditions, ULTEM 1000 was combined with 0.5% by weight talc to produce the compound for subsequent extrusion trials to produce foamed parts.

Embodiment 1

[0084] Embodiment 1 (comparative embodiment)

[0085] Polyetherimide (PEI), commercially available as ULTEM 1000 from SABIC Innovative Plastics, was used as the baseline without blowing agent or introduced air bubbles (pure resin). Under the conditions specified above, PEI was fed to an Akron single screw extruder to obtain a "+"-shaped extrudate with a relative linear density of 100%, an apparent specific gravity of 1.27, and a density reduction of 0%. The weight of a 1 meter length of extrudate is 4.6669 grams. Its properties are listed in Table 1.

Embodiment 2

[0087] The same PEI as used in Example 1 was combined with blowing agent ((ULTEM FUL-C20 from SABIC Innovative Plastics) in an amount of 11.4 g / 4540 g PEI). It was then extruded in an Akron single screw extruder under the conditions specified above. The resulting extrudate exhibited a relative linear density of 91%, an apparent specific gravity of 1.23 and a density reduction of 3%. It shows slightly foamy. Its properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com