Microbial enzyme preservative for fruits and vegetables as well as preparation method and application method thereof

A technology of microorganisms and preservatives, which is applied in the preservation, application, and food preservation of fruits and vegetables, can solve problems such as economic losses of fruit farmers and vegetable farmers, remote vegetable and fruit planting areas, and backward anti-corrosion preservation technology, so as to solve the problems of decay and deterioration and prolong fresh-keeping. period, the effect of improving the economic benefits of fruits and vegetables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

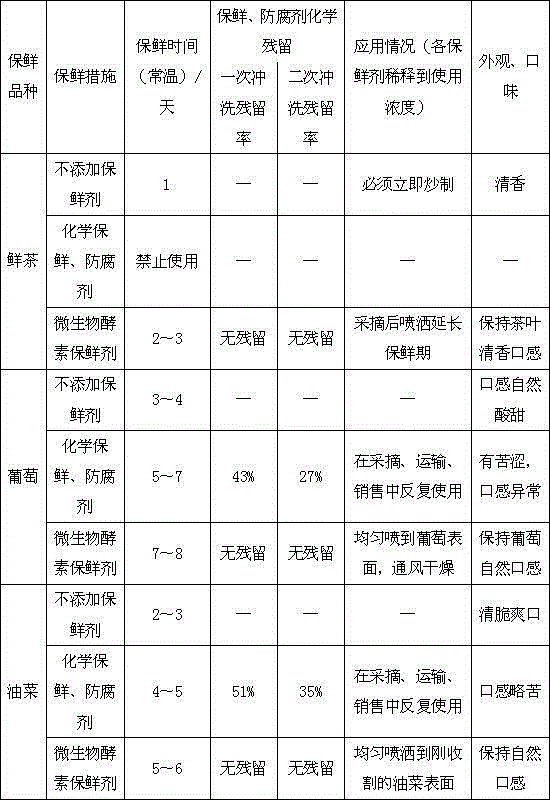

[0012] Embodiment 1: the antisepsis and fresh-keeping of tea garden picking fresh tea

[0013] The fruit and vegetable microbial enzyme antistaling agent of the present embodiment and its preparation and use method, the antistaling agent is made of the following raw materials in parts by weight:

[0014] Yeast 430g, Bacillus natto 35g, Bifidobacterium infantis 35g, Streptococcus thermophilus 35g, molasses 1150g, glucose 400g, high-purity water sterilized by high temperature and high pressure 2600ml, the number of yeast ≥ 300cfu / ml, Bacillus natto The quantity is ≥100cfu / ml, the total amount of live bacteria of Bifidobacterium infantis + Streptococcus thermophilus is ≥600,000cfu / ml, the sugar content of molasses is 75°, and the sugar content of glucose is 45°.

[0015] The preservative is prepared by using the above-mentioned raw material components, and the specific steps are as follows: First, mix molasses, glucose and high-purity water to obtain a nutrient solution, adjust t...

Embodiment 2

[0018] Embodiment 2: Preservation and fresh-keeping of grape picking

[0019] The fruit and vegetable microbial enzyme antistaling agent of the present embodiment and its preparation and use method, the antistaling agent is made of the following raw materials in parts by weight:

[0020] Yeast 460g, Bacillus natto 45g, Bifidobacterium infantis 45g, Streptococcus thermophilus 45g, molasses 800g, glucose 330g, high-purity water sterilized by high temperature and high pressure 2800ml, of which the number of yeast ≥ 300cfu / ml, Bacillus natto The quantity is ≥100cfu / ml, the total amount of live bacteria of Bifidobacterium infantis + Streptococcus thermophilus is ≥600,000cfu / ml, the sugar content of molasses is 75°, and the sugar content of glucose is 45°.

[0021] Preservatives are prepared by using the above-mentioned raw material components, and the specific steps are as follows: First, mix molasses, glucose and high-purity water sterilized by high temperature and high pressure t...

Embodiment 3

[0024] Embodiment 3: Preservation and preservation of rapeseed

[0025] The fruit and vegetable microbial enzyme antistaling agent of the present embodiment and its preparation and use method, the antistaling agent is made of the following raw materials in parts by weight:

[0026] Yeast 420g, Bacillus natto 43g, Bifidobacterium infantis 43g, Streptococcus thermophilus 43g, molasses 950g, glucose 350g, high-purity water sterilized by high temperature and high pressure 2700ml, of which the number of yeast ≥ 300cfu / ml, Bacillus natto The quantity is ≥100cfu / ml, the total amount of live bacteria of Bifidobacterium infantis + Streptococcus thermophilus is ≥600,000cfu / ml, the sugar content of molasses is 75°, and the sugar content of glucose is 45°.

[0027] The preservative is prepared by using the above-mentioned raw material components. The specific steps are as follows: First, mix molasses, glucose and high-purity water sterilized by high temperature and high pressure to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com