Baked cheese sauce and preparation technology thereof

A production process and cheese sauce technology, applied in the field of food processing, can solve the problems of waste, easy crushing, dry and hard texture, etc., and achieve the effects of reducing production costs, ensuring fluidity, and having a sweet taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

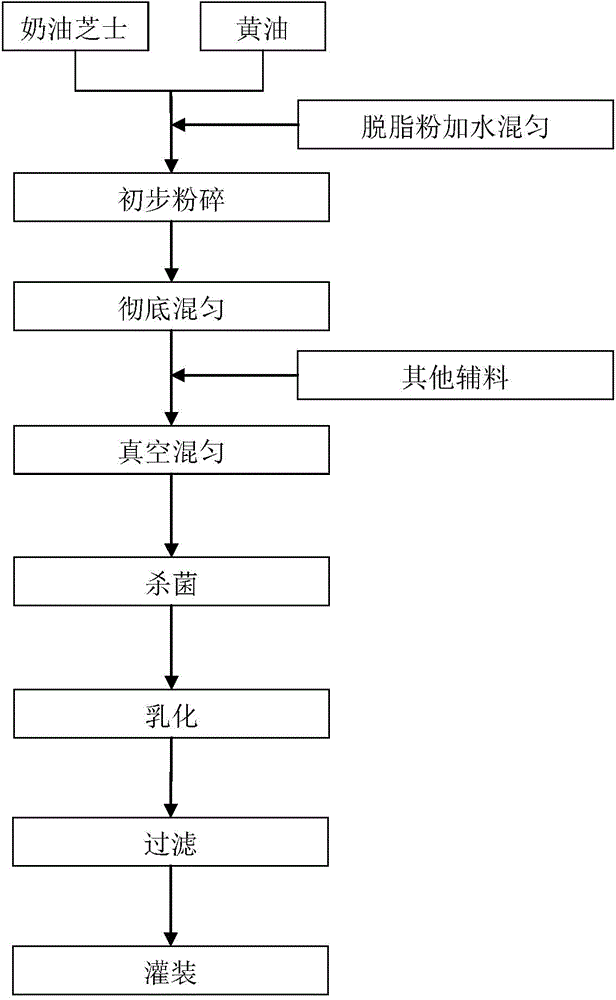

[0022] A kind of production process of baked cheese sauce is as follows:

[0023] (1) Weigh 150g of cream cheese and 100g of butter and add them to the mixer for mixing, the mixing time is 1min, and the speed is 300-500r / min;

[0024] (2) Mix 20g of defatted powder, 50g of whey powder and 100g of hot water at 30-40°C evenly, add the mixture to the mixture of step (1), add 473g of water, rotate at a speed of 500-800r / min, and mix for 2 minutes ;

[0025] (3) Transfer the material mixed in step (2) to a vacuum mixing tank, add 100g of white sugar, 20g of starch, 1g of lactic acid, 5g of sodium pyrophosphate, 1.5g of food flavor, and 0.05g of natural pigment, start the reamer, The rotation speed is 300-500r / min, the time is 1min, and the vacuum is completed at the same time, the vacuum degree is 0.06MPa, and the temperature is 35-40°C;

[0026] (4) High-temperature sterilization: adjust the rotation speed in the vacuum mixing tank to 500-800r / min, heat at 96°C, and the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com