Charging system of ceramic non-slurry pelletizing

A dry granulation and feeding system technology, applied in the field of ceramics, can solve problems such as affecting work efficiency, inability to accurately control the amount of powder feeding, large flow error, etc., to meet parameter requirements, improve work efficiency and product quality, ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

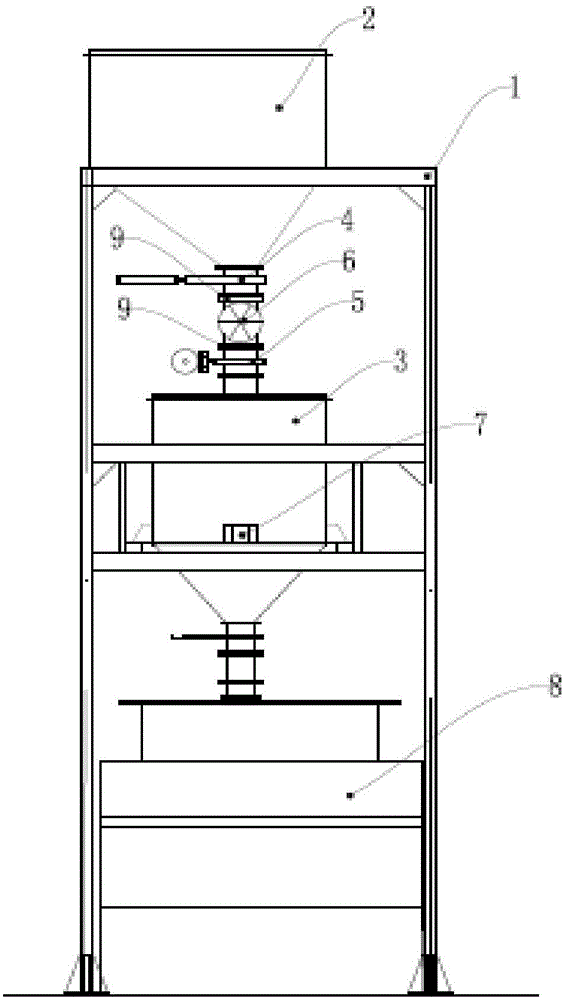

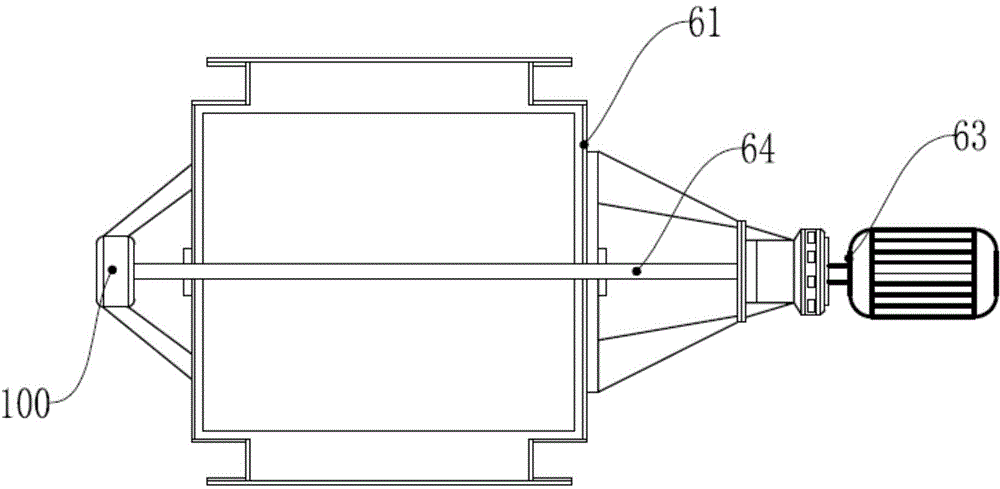

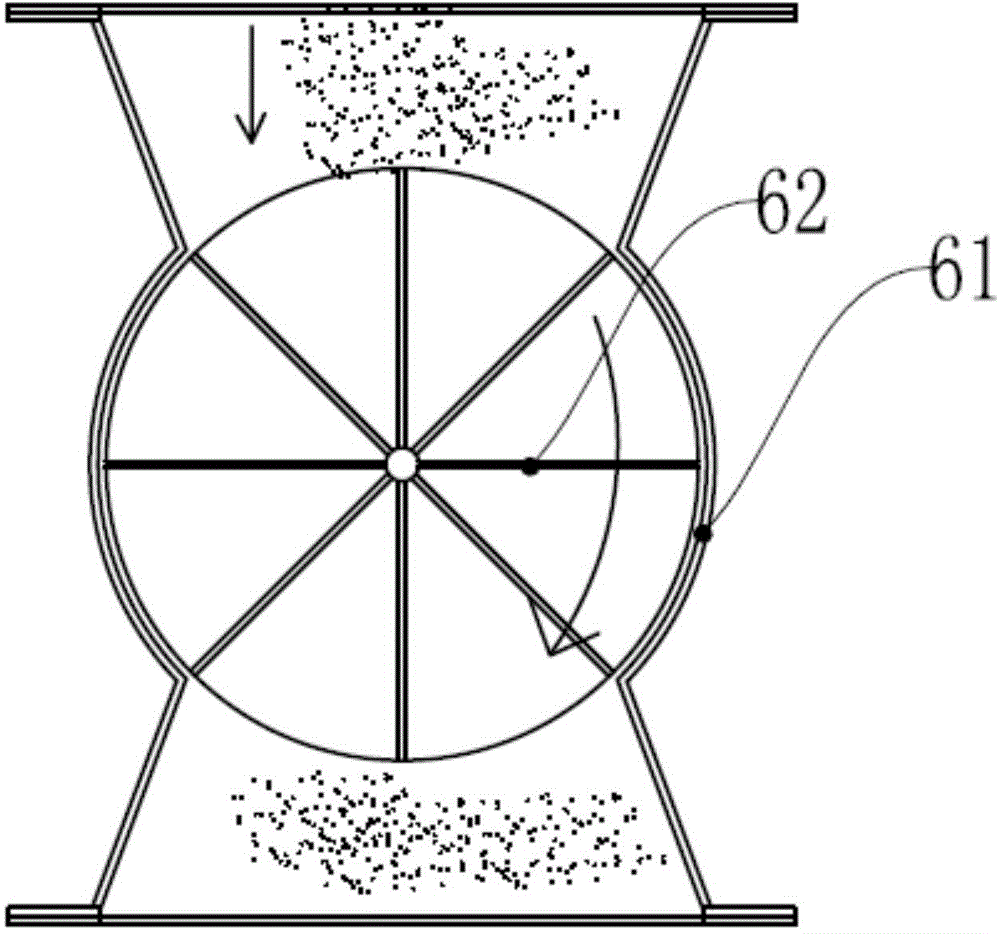

[0022] like figure 1 As shown, a feeding system for ceramic dry granulation includes a frame 1, a storage bin 2 and a weighing bin 3; the storage bin 2 and the weighing bin 3 are all installed on the frame 1; The storage bin 2 is located above the weighing bin 3, and is connected by a pipeline; it also includes a first control valve 4 and a second control valve 5, and the first control valve 4 and the second control valve 5 are arranged in the stored A feeder 6 is provided between the first control valve 4 and the second control valve 5 on the communication pipe between the silo 2 and the weighing bin 3 .

[0023] The main process of dry granulation is: raw material crushing-mixing-batching-granulation-drying-storage; that is: (1) Grinding the material into a very fine powder, (2) Grinding the crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com