Throwing Impact Crusher Sand Making Machine

A sand making machine and impact technology, applied in grain processing and other directions, can solve the problems of only 30% finished product rate, cumbersome, low efficiency, and low life expectancy, and achieve the effect of large crushing force, strong applicability, and improved durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

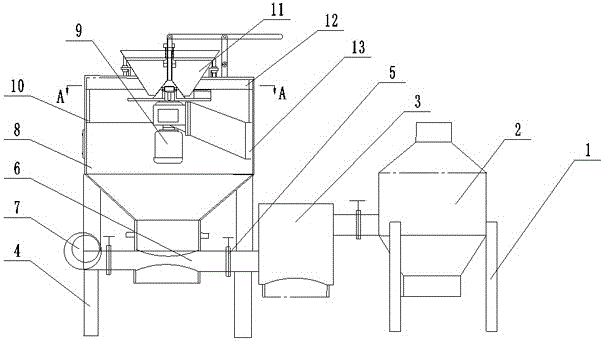

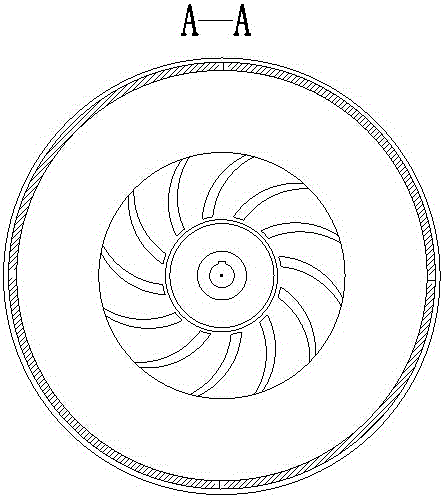

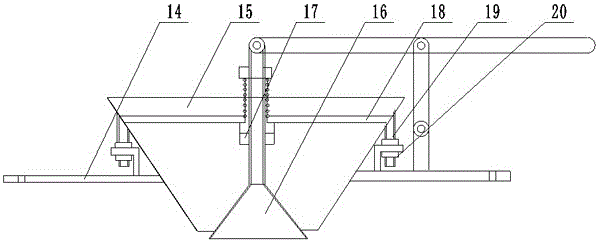

[0027] Such as Figure 1 ~ Figure 5 As shown, the projectile impact type crushed stone sand making machine of the present invention includes a hopper 11, a projectile impeller 12, an electromagnetic speed regulating motor 9, a body 8, a fan 7, a wind tube 6, a sand forming tube 3, a dust collector 2, a body The bracket 4 and the impact plate 10, the feed hopper 11 is arranged at the upper end of the body 8, the body bracket 4 is arranged at the lower end of the body 8, the projection impeller 12 is arranged in the body 8, and the projection impeller 12 is located Below the hopper 11, the ejection impeller 12 is driven by an electromagnetic speed-regulating motor 9 arranged in the body 8, the impact plate 10 is arranged on the inner side wall of the body 8, and the bottom end of the body 8 is provided with an outlet The outlet, the outlet is communicated with the middle of the air cylinder 6 arranged on the machine body support 4, the fan 7 is arranged at one end of the air cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com