A kind of preparation method of spherical submicron cobalt powder

A micron cobalt powder and submicron technology is applied in the field of preparation of spherical submicron cobalt powder, which can solve the problems of poor particle uniformity and dispersibility, wide particle size distribution and high oxygen content, and achieves a simple and easy-to-control preparation method and high production efficiency. The effect of stable quality and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

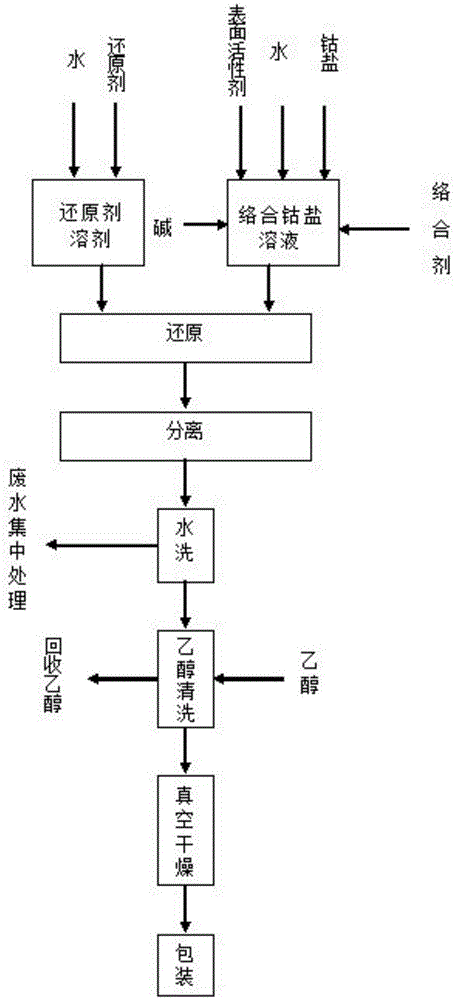

[0025] see figure 1 , the invention discloses a preparation method of spherical submicron cobalt powder, comprising steps:

[0026] The step of making the complexed cobalt salt solution: dissolving the cobalt salt and the surfactant in water and stirring evenly, adding a complexing agent into the cobalt salt solution for mixing and reacting;

[0027] The steps of making the reducing agent solvent: dissolving the reducing agent in water;

[0028] Heating the complexed cobalt salt solution, adding alkali to the complexed cobalt salt solution to make it alkaline; then mixing the reducing agent solvent with the complexed cobalt salt solution, and obtaining a submicron cobalt powder filter cake through solid-liquid separation, which is washed and removed Impurities in the filter cake; the washed filter cake is washed with absolute ethanol to remove water; the submicron cobalt powder filter cake washed with absolute ethanol is vacuum dried to remove ethanol and trace moisture to ob...

Embodiment 1

[0040] A preparation method of submicron cobalt powder, comprising:

[0041] 0.225 mol CoCl 2 Dissolve 4.5g of PVP in water and mix evenly, then add 0.135mol ammonia water and stir well to obtain 450ml complex cobalt salt solution; mix 0.43molN 2 h 4 ·H 2 O and 0.02 mol sodium borohydride are miscible in water to obtain 450ml reducing agent solvent;

[0042] Heat the complexed cobalt salt solution to 80°C, adjust the pH value of the complexed cobalt salt solution to 12.0 with 6.0mol / L sodium hydroxide solution, and then add the reducing agent solvent into the complexed cobalt salt solution for 30 minutes. The temperature of the reaction system was maintained at 80°C for 40 minutes, and then cold water was added to cool to room temperature (10-30°C); the reaction product was centrifuged, the filter cake was washed with water to remove impurities in the filter cake, and the waste water was treated centrally; The cake is washed with absolute ethanol to remove water, and the a...

Embodiment 2

[0044] A preparation method of submicron cobalt powder, comprising:

[0045] 0.35 mol CoSO 4 Dissolve 7.0g of PVA in water and mix evenly, then add 0.175mol ethylenediamine and stir thoroughly to obtain 350ml complex cobalt salt solution; mix 1.65molN 2 h 4 ·H 2 0.01 mol potassium borohydride is miscible in water to obtain 550ml reducing agent solvent;

[0046] Heat the complexed cobalt salt solution to 60°C, adjust the pH value of the complexed cobalt salt solution to 11.5 with 2.0mol / L potassium hydroxide solution, then add the reducing agent solvent into the complexed cobalt salt solution, and the feeding time is 50min , the temperature of the reaction system was maintained at 60°C for 50 minutes, and then cold water was added to cool to room temperature (10-30°C); the reaction product was centrifuged, the filter cake was washed with water to remove impurities in the filter cake, and the waste water was treated centrally; The filter cake is washed with absolute ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com