Micro-vibration welding device and method

A welding device and micro-vibration technology, applied in welding equipment, electrode support devices, vibration fixtures for electrodes, etc., can solve the problems of reducing the mechanical properties of welded joints and processing quality, deformation, and coarse metal grains, etc., to achieve welding Fine stitching, simple equipment, and good tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

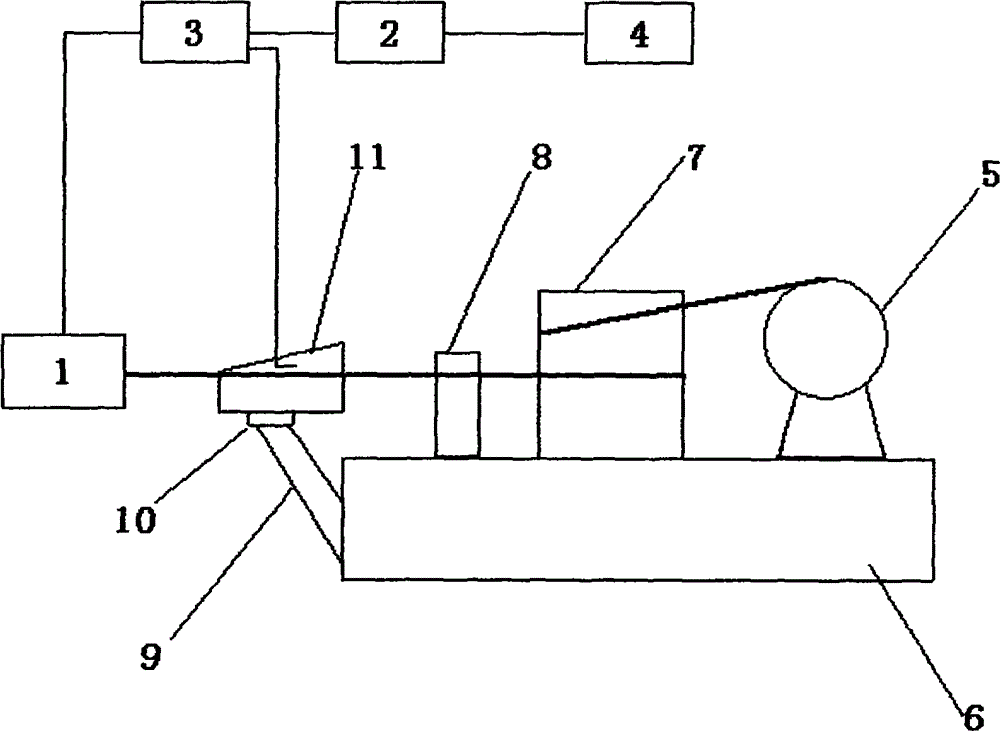

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] as attached figure 1 As shown, the present invention proposes a micro-vibration welding device, which is provided with an arc welding power source, a conductive rod, a wire, an electrode holder 1, a welding wire supply mechanism, and a nozzle, and is characterized in that it is also provided with an electrode holder 1. Connected micro-vibration mechanism, said micro-vibration mechanism includes vibration generation part 2, vibration transmission part 3 and vibration power supply 4, wherein vibration generation part 2 is connected with vibration transmission part 3, vibration transmission part 3 adopts vibration generation part 2 The connected guide rod and buffer body, the buffer body is arranged at the end of the guide rod and conflicts with the electrode holding body 1, and the front end of the guide rod is connected with the vibration generating part.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com