Rare earth doped lead-free frit and electrical component sealing method utilizing the same

A technology for electrical components and glass frit, applied in the field of lead-free glass frit, can solve problems such as environmental hazards, and achieve the effects of easy processing and excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Example 1. [Manufacture of glass frit composition]

[0087] The glass frits of Examples 1-4 were produced with the material composition of the following Table 1, and the unit in Table 1 is mole %.

[0088] Table 1 (mol%)

[0089]

[0090]Heat the glass frit mixture in the above Table 1 to melt the composition, such as mixing in a high-temperature furnace (1650 ° C), and then pour cold water or liquid nitrogen on the melt to quench and fracture. -mill) repeated grinding and mixing, the required glass frit particle size 0.1-20um can be obtained, which meets the size of 325 mesh or 400 mesh screen. The glass frit of Examples 1-4 is characterized in that the softening temperature Tdsp is 300-400° C., which is suitable for low-temperature processing of the glass frit.

Embodiment 2

[0091] Example 2 [Manufacture of glass frit paste composition]

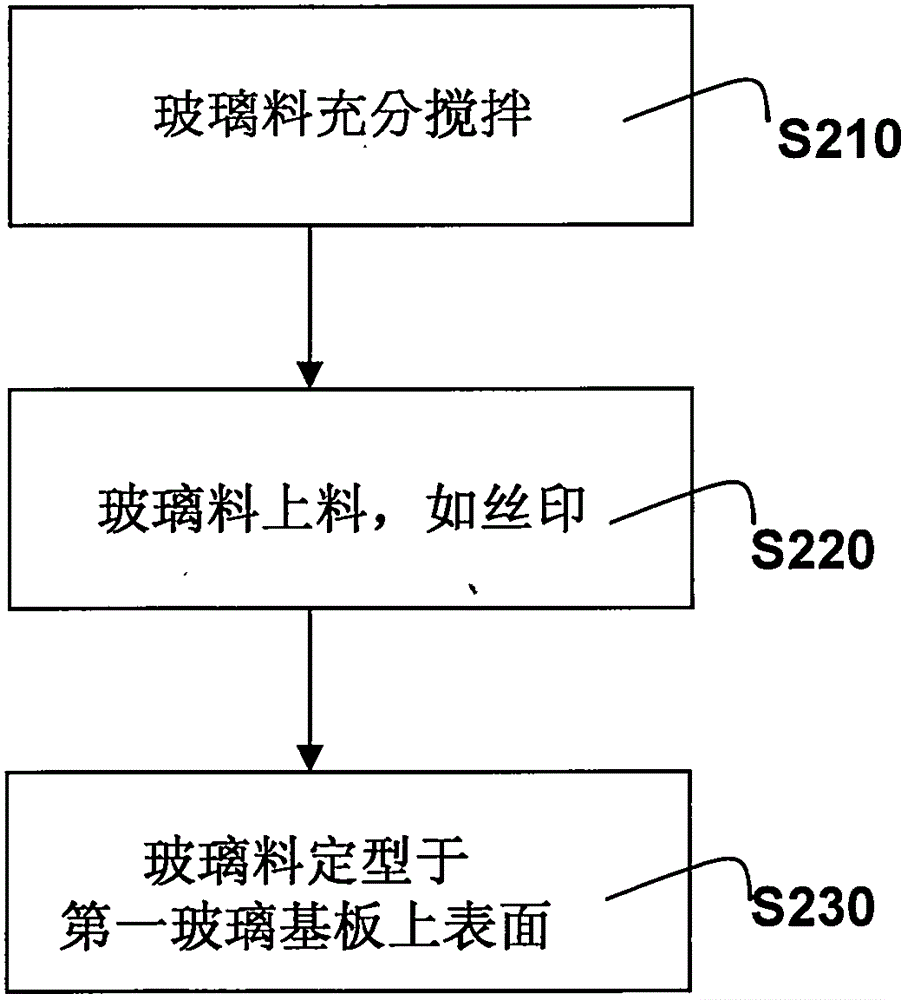

[0092] Frit paste compositions were made using the frit mixtures of Examples 1-4 above. Weigh 70 parts by weight of the glass frit mixture in the above-mentioned examples 1-4 with 30 parts by weight of EC ethyl cellulose / BCA butyl carbitol acetate, AC acrylic resin / 2,2,4-trimethyl Base-1.3 pentanediol monoisobutyrate (texanol alcohol ester), or polyalkylene carbonate (Polyalkylene Carbonate) / triglyme dimethyl ether to make the following four glass frit paste compositions (No. 1 -4). By adjusting different weight ratios of the polymer binder and the solvent, different viscosities of the glass frit paste composition can be obtained, so as to be suitable for the operation of the screen printing process.

[0093] Furthermore, the glass frit paste composition is further inverted on a three-roll machine for one or several times of mixing, which can achieve a more ideal silk screen printing effect.

[0094] Table 2. ...

Embodiment 3

[0108] Example 3 [Hermetic sealing of OLED element]

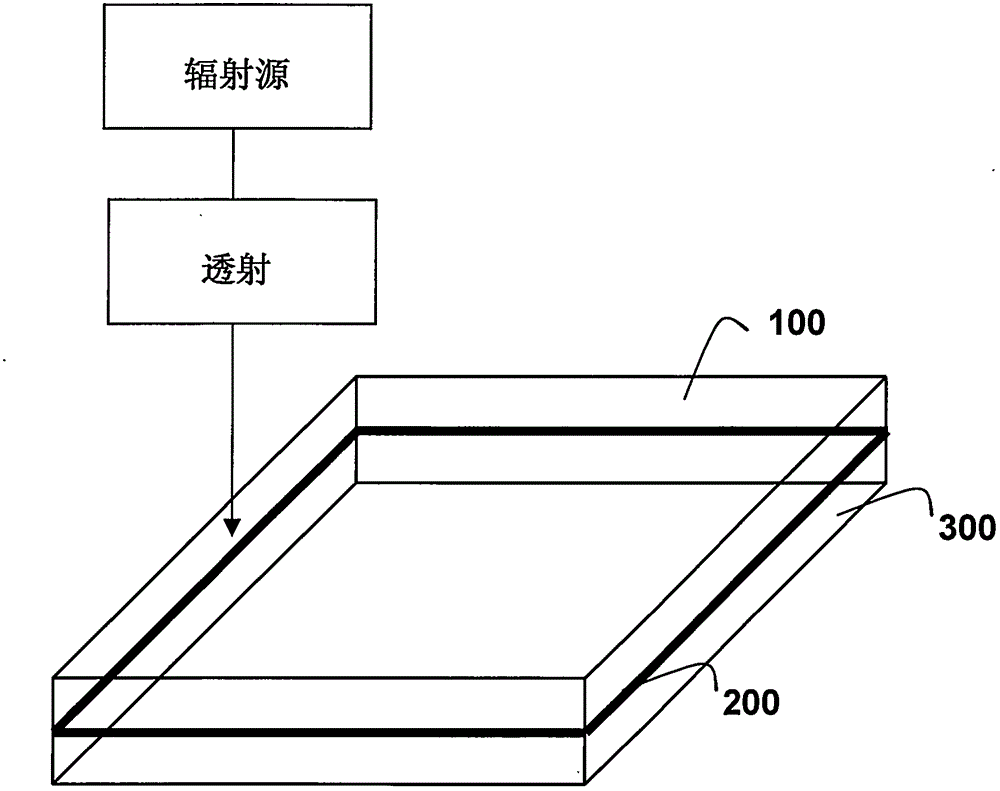

[0109] The present invention discloses that the glass frit is fixed on a predetermined position of the first glass substrate through a screen printing process or a dispensing coating process, and a radiation source is used to heat the glass frit to weld the first glass substrate to the first glass substrate. A hermetic seal dam is formed on and between two glass substrates.

[0110] The hermetic sealing method of the OLED element will be described in detail below using the screen printing process and the laser radiation heating technology. It should be understood that the frit paste composition and hermetic sealing technology described in the embodiments of the present invention are not limited to screen printing or laser radiation heating.

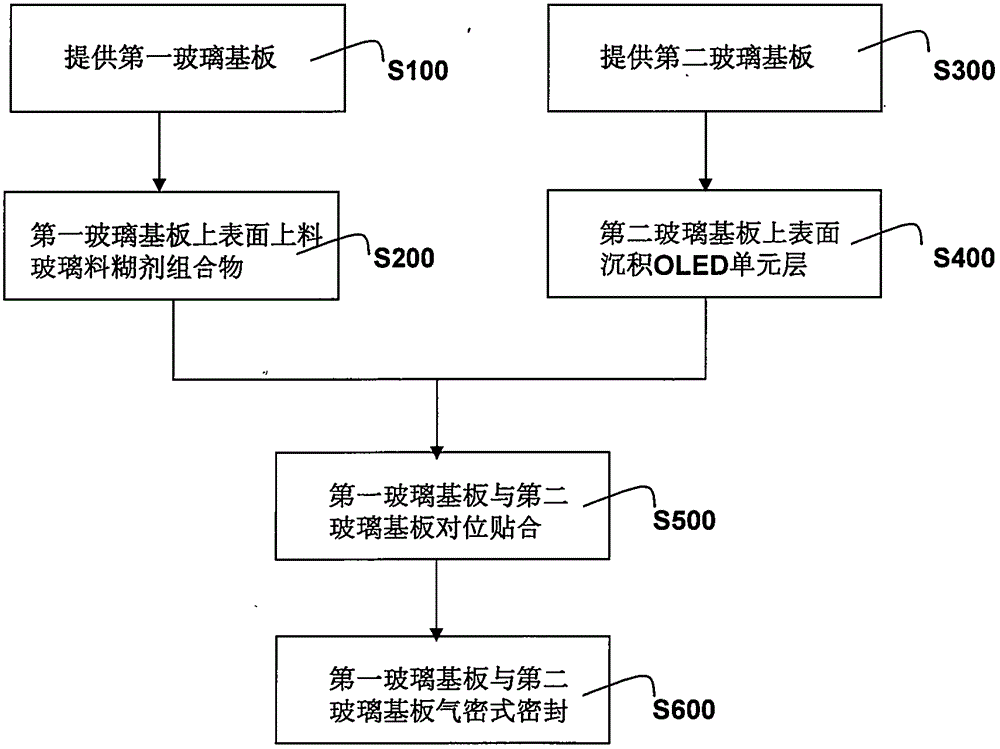

[0111] Hermetic sealing process, see figure 1 and figure 2 As shown, the details are as follows:

[0112] a) Preparation of frit paste composition

[0113] The above prepared gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com