A method and device for combined removal of organic matter and magnesium ions in zinc sulfate solution

A zinc sulfate solution and combined removal technology, applied in the direction of improving process efficiency, can solve problems such as loss, difficulty in recovery, reduction in electrolytic current efficiency, etc., to achieve stable quality, improve decomposition and removal rate, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

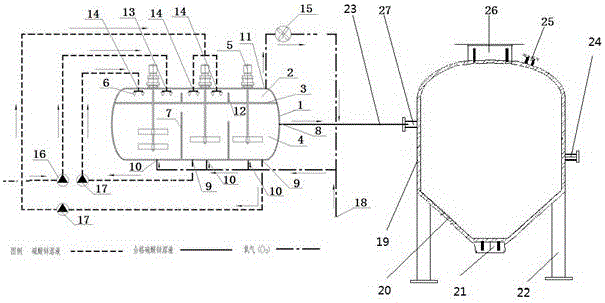

[0047] A method for jointly removing organic matter and magnesium ions in zinc sulfate solution, the specific steps are:

[0048] 1) The COD value of organic matter produced in the hydrometallurgical process is 300 mg / L, Mg 2+ For a zinc sulfate solution with a concentration of 12 g / L and a pH value of 2.5, use a pressurizing device to increase the pressure to 0.5 MPa, and at the same time, use a heating device to increase the temperature of the zinc sulfate solution to 120°C;

[0049] 2) Add the zinc sulfate solution that has been pressurized and heated to the device for removing organic matter in the zinc sulfate solution by pressurized atomization. First, use the atomizer 6 in the device to atomize the zinc sulfate solution to make the zinc sulfate The solution is dispersed into particles and fine lines;

[0050] 3) After the atomized zinc sulfate solution fully reacts with oxygen in the atomization zone 2 of the device and condenses into liquid particles, it settles to th...

Embodiment 2

[0059] A method for jointly removing organic matter and magnesium ions in zinc sulfate solution, the specific steps are:

[0060] 1) The COD value of organic matter produced in the hydrometallurgical process is 300 mg / L, Mg 2+ For a zinc sulfate solution with a concentration of 65 g / L and a pH value of 5.4, use a pressurizing device to increase the pressure to 0.5 MPa, and at the same time, use a heating device to increase the temperature of the zinc sulfate solution to 120 °C;

[0061] 2) Add the zinc sulfate solution that has been pressurized and heated to the device for removing organic matter in the zinc sulfate solution by pressurized atomization. First, use the atomizer 6 in the device to atomize the zinc sulfate solution to make the zinc sulfate The solution is dispersed into particles and fine lines;

[0062] 3) After the atomized zinc sulfate solution fully reacts with oxygen in the atomization zone 2 of the device and condenses into liquid particles, it settles to t...

Embodiment 3

[0071] A method for jointly removing organic matter and magnesium ions in zinc sulfate solution, the specific steps are:

[0072] 1) The COD value of organic matter produced in the hydrometallurgical process is 850mg / L, Mg 2+ For a zinc sulfate solution with a concentration of 65 g / L and a pH value of 5.4, use a pressurizing device to increase the pressure to 4.5 MPa, and at the same time, use a heating device to increase the temperature of the zinc sulfate solution to 250°C;

[0073] 2) Add the zinc sulfate solution that has been pressurized and heated to the device for removing organic matter in the zinc sulfate solution by pressurized atomization. First, use the atomizer 6 in the device to atomize the zinc sulfate solution to make the zinc sulfate The solution is dispersed into particles and fine lines;

[0074]3) After the atomized zinc sulfate solution fully reacts with oxygen in the atomization zone 2 of the device and condenses into liquid particles, it settles to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com