Carbon fiber surface treatment method

A surface treatment and carbon fiber technology, applied in the field of carbon fiber surface treatment technology, can solve problems such as inability to continue production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

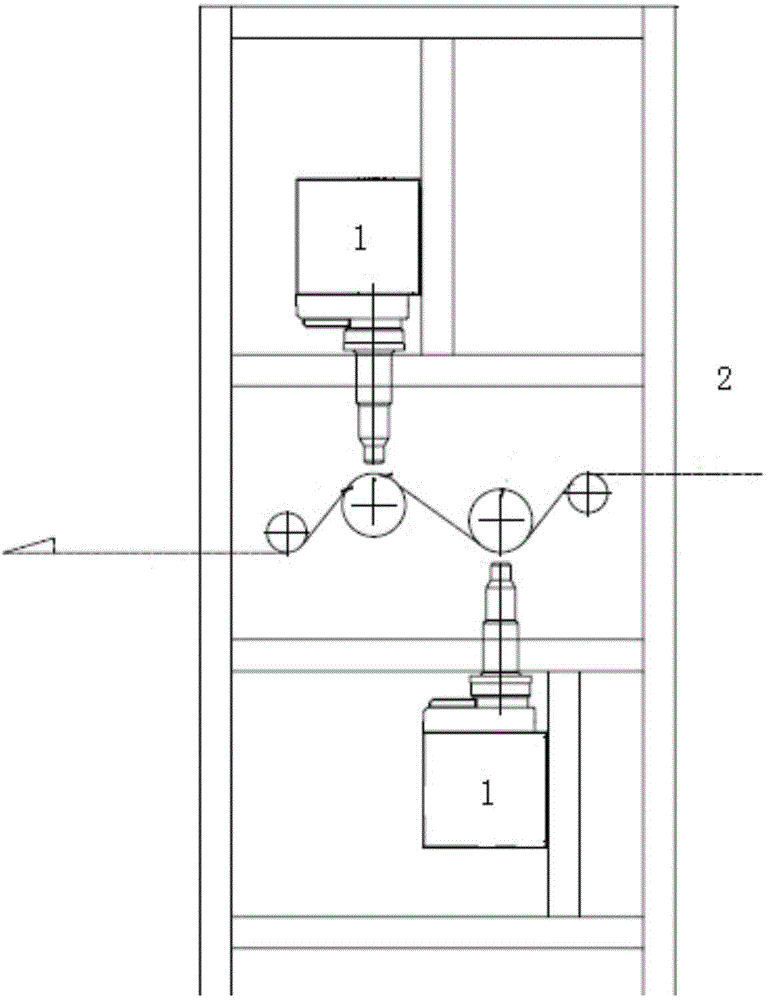

[0012] use figure 1 The low-temperature plasma device shown treats the carbon fiber surface. Under an atmospheric pressure environment, nitrogen gas is used as the carbon fiber surface treatment medium to generate low-temperature plasma, and the low-temperature plasma bombards the surface of the moving carbon fiber tow. The low-temperature plasma is a jet-type low-temperature plasma. The running speed of carbon fiber tow is 90m / h; the working environment temperature of carbon fiber treatment is 25°C; the gap between carbon fiber tow 2 and jet low-temperature plasma emission device 1 is 8mm; the environmental humidity of carbon fiber surface treatment is 60%; the power range of carbon fiber surface treatment is 1000W / bundle; low temperature plasma carbon fiber surface treatment temperature 80 ℃. The total content of polar functional groups (mainly -OH, -C=O, -COOH) on the surface of carbon fiber is 22.32%, and the interlaminar shear strength is 90MPa.

Embodiment 2

[0014] use figure 1 The low-temperature plasma device shown treats the carbon fiber surface. Under an atmospheric pressure environment, nitrogen gas is used as the carbon fiber surface treatment medium to generate low-temperature plasma, and the low-temperature plasma bombards the surface of the moving carbon fiber tow. The low-temperature plasma is a jet-type low-temperature plasma. The running speed of carbon fiber tow is 90m / h; the working environment temperature of carbon fiber treatment is 25°C; the gap between carbon fiber and plasma emission device is 8mm; the environmental humidity of carbon fiber surface treatment is 60%; the power range of carbon fiber surface treatment is 1400W / bundle; low temperature plasma The body carbon fiber surface treatment temperature is 80°C. The total content of polar functional groups (mainly -OH, -C=O, -COOH) on the surface of carbon fiber is 23.2%, and the interlaminar shear strength is 100MPa.

Embodiment 3

[0016] use figure 1 The low-temperature plasma device shown treats the carbon fiber surface. Under an atmospheric pressure environment, nitrogen gas is used as the carbon fiber surface treatment medium to generate low-temperature plasma, and the low-temperature plasma bombards the surface of the moving carbon fiber tow. The low-temperature plasma is a jet-type low-temperature plasma. The running speed of carbon fiber tow is 90m / h; the working environment temperature of carbon fiber treatment is 25°C; the gap between carbon fiber and plasma emission device is 8mm; the environmental humidity of carbon fiber surface treatment is 60%; the power range of carbon fiber surface treatment is 1600W / bundle; low temperature plasma The body carbon fiber surface treatment temperature is 80°C. The total content of polar functional groups (mainly -OH, -C=O, -COOH) on the surface of carbon fiber is 23.1%, and the interlaminar shear strength is 105MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com