Pulping method of special pulp

A technology of pulping and pulping, which is applied in pulping with inorganic alkali, pulping of cellulose raw materials, textiles and papermaking, etc., can solve the problems of inability to produce high-viscosity dissolving wood pulp, and prevent lignin condensation and desorption The effect of removing lignin and protecting cellulose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

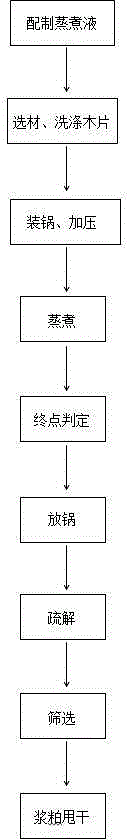

Method used

Image

Examples

Embodiment 1

[0027] Add 20L of factory water into the cooking liquid preparation bottle, weigh 300g of ammonium bicarbonate, dissolve in the factory water, shake to accelerate the dissolution, introduce sulfur dioxide gas, control the gas flow, shake properly, accelerate the uniform dissolution reaction of the base, and promote the escape of carbon dioxide. Measure the total acid and free acid of the cooking liquid, and calculate the combined acid until the total acid is 6%, the combined acid is 1.5%, and the introduction of sulfur dioxide is stopped;

[0028] Selection of cooking raw materials The cooking raw materials are good radiata pine materials, the slice specifications are 12-17mm in length, 2-4mm in thickness, and the width has little influence. Remove larger wood chips and sawdust, wash the wood chips with factory water, remove non-fibrous impurities, and keep the wood chips The water content is 60%, which accelerates the penetration of the medicinal liquid, which is beneficial to...

Embodiment 2

[0032] Add 20L of factory water into the cooking liquid preparation bottle, weigh 320g of sodium carbonate, dissolve in the factory water, shake to accelerate the dissolution, introduce sulfur dioxide gas, control the gas flow, shake properly, accelerate the uniform dissolution reaction of the base, promote the escape of carbon dioxide, and measure For the total acid and free acid of the cooking liquid, the combined acid is calculated until the total acid is 5.9% and the combined acid is 1.4%, and the introduction of sulfur dioxide is stopped;

[0033] The raw material for cooking is radiata pine leftovers. The length of the slices is 12-17mm, the thickness is 2-4mm, and the width has little effect. Remove larger wood chips and sawdust, wash the wood chips with factory water, remove non-fibrous impurities, and keep the wood chips at 59% moisture. , to accelerate the penetration of the liquid medicine, which is beneficial to the early stage of cooking;

[0034] The amount of wo...

Embodiment 3

[0037] Add 20L of factory water into the cooking liquid preparation bottle, weigh 280g of ammonium bicarbonate, dissolve in the factory water, shake to accelerate the dissolution, introduce sulfur dioxide gas, control the gas flow, shake properly, accelerate the uniform dissolution reaction of the base, and promote the escape of carbon dioxide. Measure the total acid and free acid of the cooking liquid, calculate the combined acid, until the total acid is 6%, the combined acid is 1.4%, stop feeding sulfur dioxide;

[0038] The raw material for cooking is radiata pine. The length of slices is 12-17mm, the thickness is 2-4mm, and the width has little effect. Larger wood chips and sawdust are removed, and the wood chips are washed with factory water to remove non-fibrous impurities, so that the water content of the wood chips is kept at 55%. , to accelerate the penetration of the liquid medicine, which is beneficial to the early stage of cooking;

[0039]The amount of wood chips ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com