Reactant metering and delivering device for internal combustion engine tail gas purification and aftertreatment system

A technology of exhaust gas purification and conveying device, which is used in exhaust gas treatment, exhaust device, internal combustion piston engine, etc., can solve problems such as the failure of the urea solution system to work properly, the easy dehydration and crystallization at the urea outlet of the metering pump, and the damage of the urea metering device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

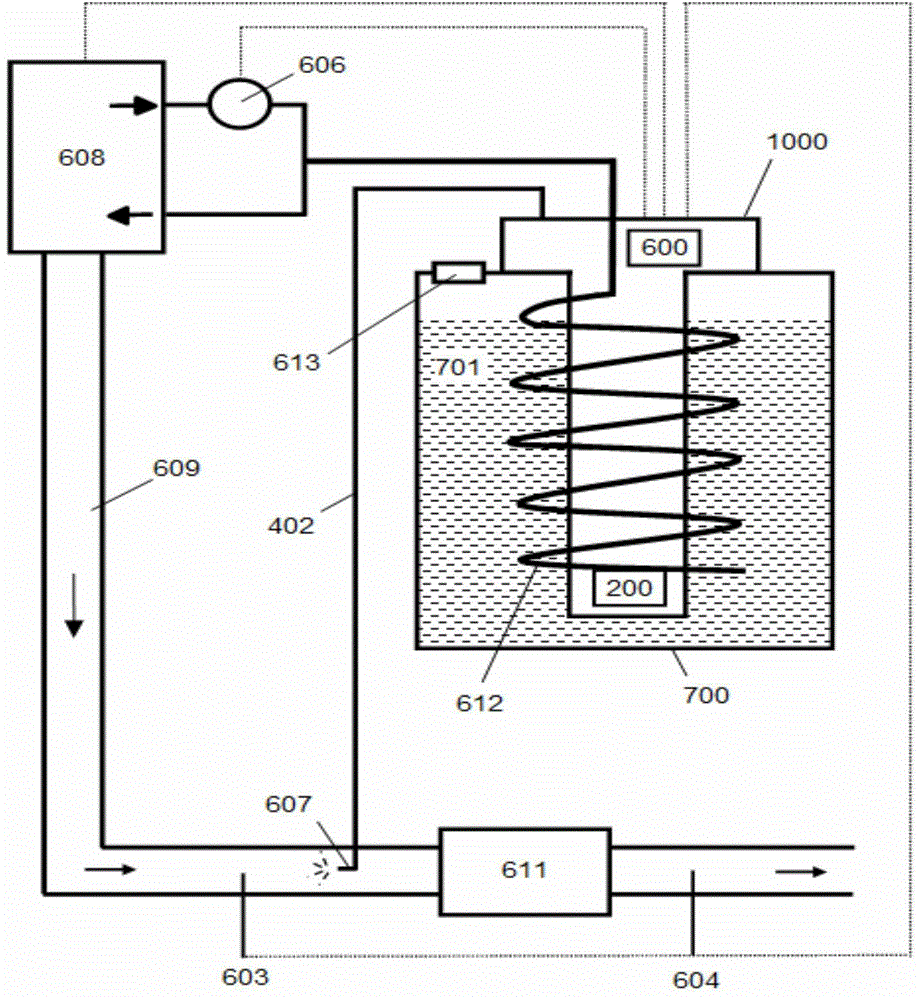

[0034] Such as figure 1 As shown, an airless vehicle exhaust aftertreatment system: including engine 608, exhaust pipe 609, nozzle 607, SCR catalyst 611, SCR pre-SCR temperature and NOx sensor 603, SCR post-SCR temperature and NOx sensor 604, coolant circulation control Valve 606, urea storage tank 700, heat exchanger 612 and urea metering device 1000;

[0035] The pre-SCR temperature and NOx sensor 603, the nozzle 607, the SCR catalyst 611, and the post-SCR temperature and NOx sensor 604 are sequentially arranged on the exhaust pipe 609;

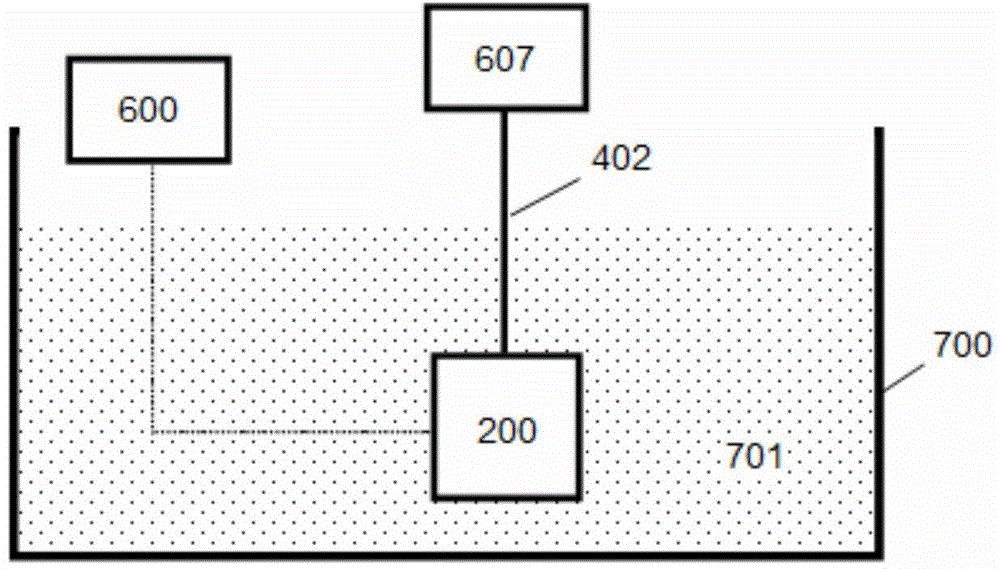

[0036] The metering device 1000 is integrated with the urea storage tank 700 .

[0037] A urea filling port (not shown) and a pressure regulating valve 613 are also installed on the top of the urea storage tank 700 . The urea storage tank 700 has a built-in heat exchanger 612, which is connected with the cooling circulation liquid of the engine 608. When the urea needs to be heated in cold weather, the controller 600 opens the engine cool...

Embodiment 2

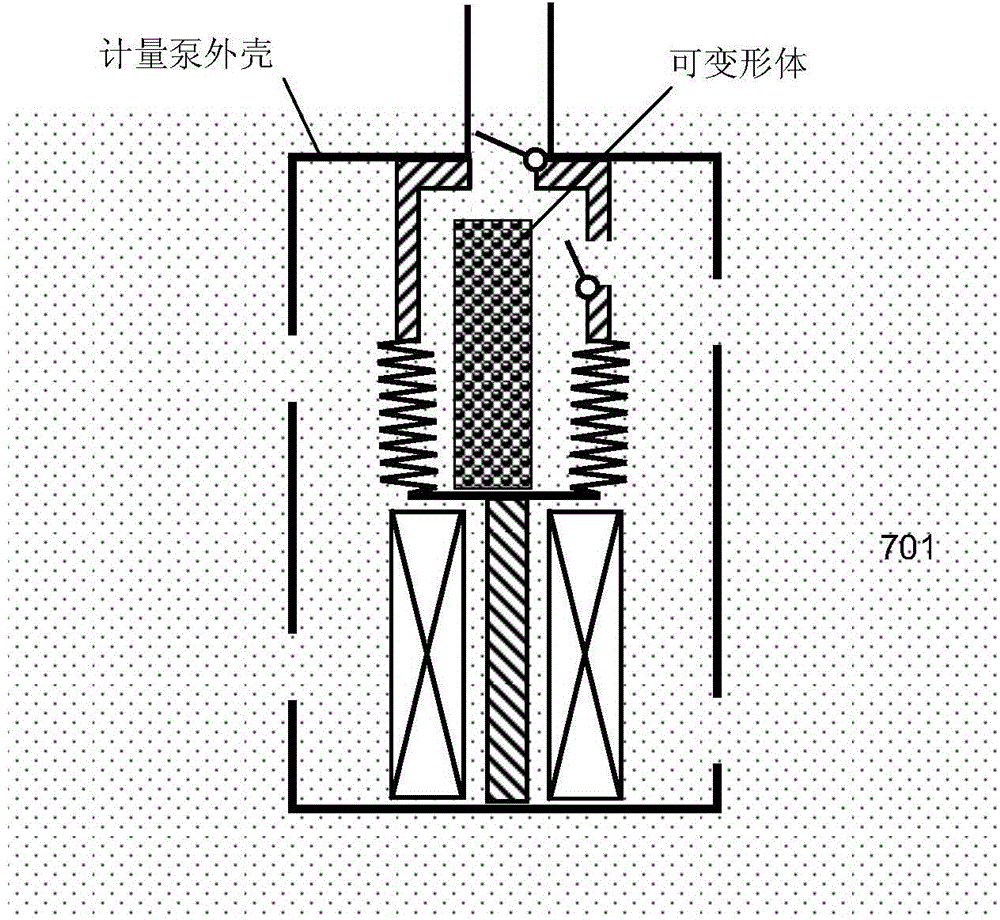

[0042] On the basis of Embodiment 1, different from Embodiment 1, as a further improvement, in order to protect the internal core parts of the metering pump from being damaged due to the expansion of the urea freezing volume, a or multiple deformable bodies, such as image 3 shown. The deformable body can be made of appropriate materials, and there is little deformation in the working pressure range of the metering pump (generally less than 10bar), or the amount of deformation is known, so that the metering accuracy will not be significantly affected; but at higher pressures (such as greater than 10bar), it is easy to deform elastically, so that when the urea freezes and expands, it can absorb the pressure in the liquid cavity inside the metering pump, and avoid damage to other parts in the metering pump due to excessive pressure. After the urea solution is thawed and the pressure in the pump returns to normal, the deformable body returns to its original shape.

Embodiment 3

[0044] Such as Figure 4 As shown, on the basis of Embodiment 1, air assistance is added to form an air-assisted vehicle exhaust after-treatment system. At this time, the difference from Embodiment 1 is that the urea metering device 1000 further includes an air switching valve 100 . The air switching valve 100 is connected with the controller 600 through wires and is controlled by the controller 600 to switch. The inlet end of the air switch valve 100 introduces compressed air into the air control valve 100 through the air delivery pipe 101 , and the outlet end is firstly connected to the metering pump 200 through the injection pipe 402 , and then connected to the nozzle 607 in series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com