High-power TLGF-HY-55-II material air blower

A TLGF-HY-55-II, 1.TLGF-HY-55-II technology, applied in liquid fuel engines, mechanical equipment, machines/engines, etc., can solve the problems of high noise, high pressure, large flow, etc., Achieve the effect of reducing noise, reducing consumption and processing, and increasing air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical solution of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

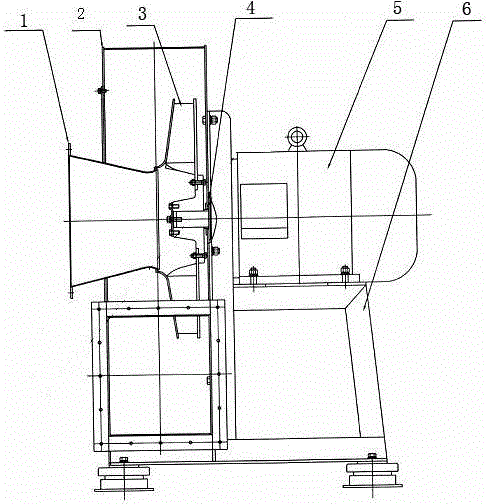

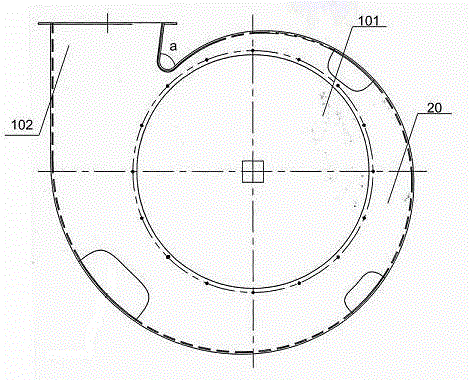

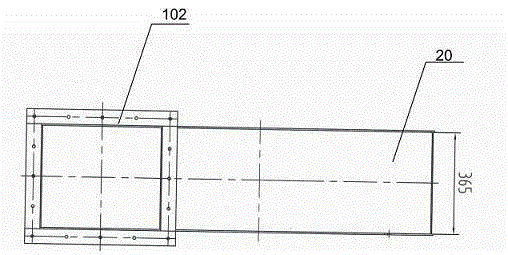

[0022] Such as figure 1 The TLGF-HY-55-II high-power material blower shown includes air inlet ring 1, casing 2, impeller 3, sealing cover 4, motor 5, and base 6. Such as Figure 2-4 As shown, the casing includes a tuyere 10 and a housing 20, and the tuyere includes an air inlet 101 and an air outlet 102; And it is recessed into the housing 20, so that the inside of the housing 20 communicates with the outside; the air inlet 101 is a hollow quadrilateral structure with openings at both ends, located on the curved surface of the housing 20, and communicates with the inside and outside of the housing 20; The circular radius of the section of the housing 20 gradually increases, and the curved surface of the housing 20 is involute, so that the radii of the two connection po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com