Submersible pump motor testing method and device with self-water feeding pressurization system

A technology for motor testing and pressurization systems, applied in measuring devices, instruments, etc., can solve the problem of corrosion damage to motor housing seals and insulation performance, affecting the stability and service life of submersible pumps, connecting shafts and submersible pumps Problems such as damage to the solid particles of the blade can be achieved to improve the comprehensiveness and accuracy of detection data acquisition, reduce the use cost and maintenance cost, and improve the applicability of the use site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

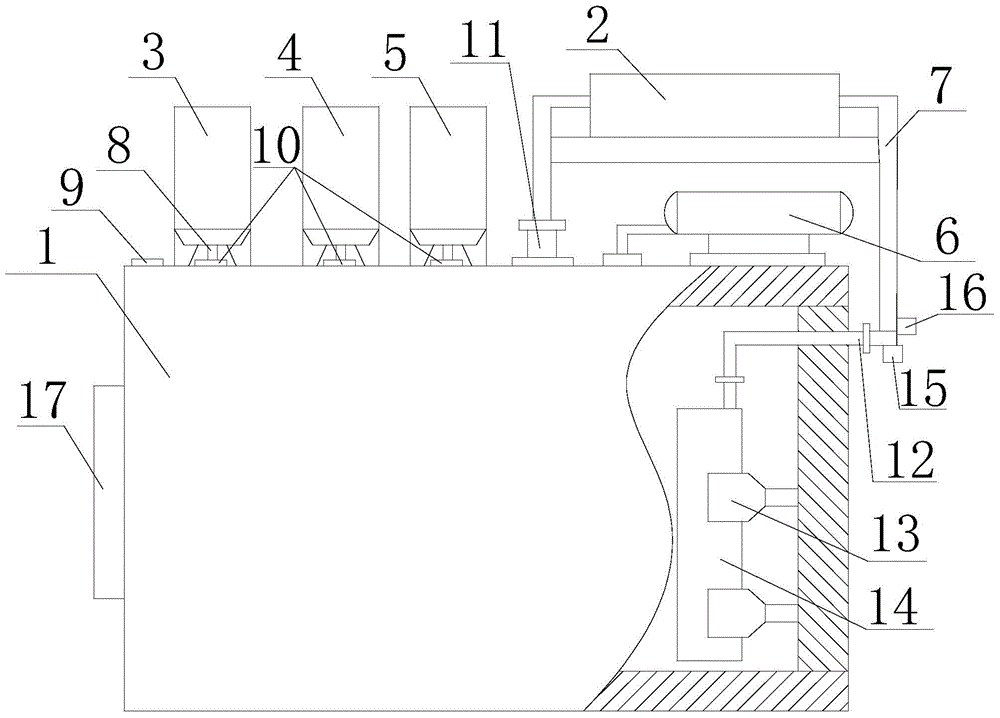

[0024] Example 1: Set the water body in the actual use environment of the submersible pump with a PH value of 6, and the water contains a small amount of sediment, and the operating position of the submersible pump is at a depth of 50 meters. When performing a simulation test on the operation of the submersible pump motor, then:

[0025] The test method of the submersible pump motor with self-filling water pressurization system, first install the submersible pump to be tested into the water source tank through the submersible pump positioning bracket and connect the pipelines, and then fill the water source tank with a battery to ensure the normal operation of the submersible pump. Sufficient water source, and according to the actual temperature of the water source, adjust the temperature of the water source tank to make it the same as the temperature of the natural environment water body, then start the submersible pump, conduct corrosion resistance detection of the motor of th...

Embodiment 2

[0030] Embodiment 2: During the simulation test of the submersible pump motor at a depth of 100 meters, then:

[0031]The test method of the submersible pump motor with self-filling water pressurization system, first install the submersible pump to be tested into the water source tank through the submersible pump positioning bracket and connect the pipelines, and then fill the water source tank with a battery to ensure the normal operation of the submersible pump. Sufficient water source, and according to the temperature of the groundwater source at a depth of 100 meters, adjust the temperature of the water source tank to make it the same as the temperature of the natural environment water body, then start the submersible pump, conduct corrosion resistance detection of the motor of the submersible pump, motor head detection and submersible pump Motor and impeller wear detection:

[0032] Motor head detection, according to the actual depth of the submersible pump, adjust the in...

Embodiment 3

[0033] Embodiment 3: When carrying out the simulation test of the motor operation within the general scope of the submersible pump, first set the pH value of the test water source to be 5, 6.5 and 8 respectively, the simulated value of the depth of the water source is 20 meters, 50 meters and 100 meters, and the solid impurities are respectively For sand particles and metal particles, then:

[0034] The test method of the submersible pump motor with self-filling water pressurization system, first install the submersible pump to be tested into the water source tank through the submersible pump positioning bracket and connect the pipelines, and then fill the water source tank with a battery to ensure the normal operation of the submersible pump. Sufficient water source, then start the submersible pump, conduct motor corrosion resistance test, motor lift test and submersible pump motor and impeller wear test on the submersible pump motor:

[0035] Corrosion resistance test of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com