Honeycomb-shaped SCR catalyst rapid aging experimental device

An SCR catalyst and rapid aging technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long time, high energy consumption, high cost, etc., and achieve the effects of reducing errors, saving costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

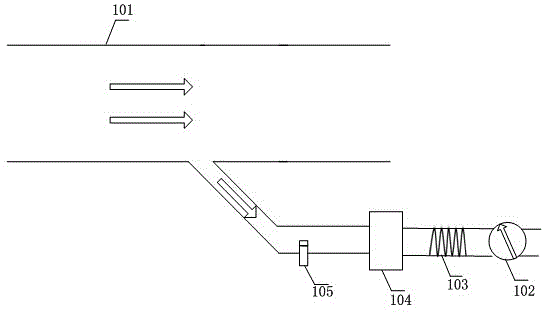

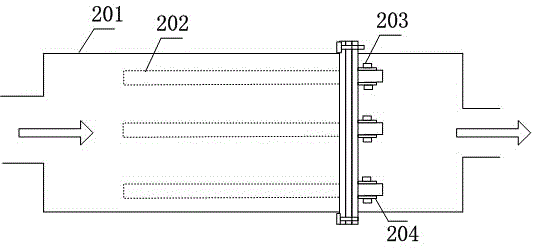

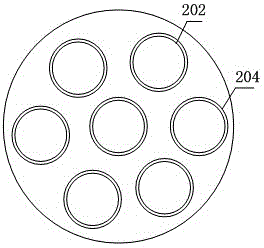

[0019] The invention is based on simulating the exhaust gas test system of a diesel engine, adopts steel pipe drainage, and introduces a part of the exhaust gas into a honeycomb sample aging device. When the simulated diesel engine exhaust test system is running, the exhaust gas with controllable temperature and flow flows into the exhaust pipe, and part of the flow flows into the honeycomb sample aging device. There is a temperature sensor at the front end of the device to measure the temperature of the honeycomb SCR catalyst for high-temperature rapid aging, and a cooling device at the rear end to reduce the temperature so that the flowmeter can measure the flow rate of the airflow passing through the honeycomb sample aging device. The whole honeycomb sample aging device is to fix the quartz tube in a small steel pipe, and there are many small holes slightly larger than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com