Process for preparing electrode material of sodium-ion battery by use of ammonium jarosite and chalcanthite

The technology of sodium ion battery and jarosite is applied in battery electrodes, secondary batteries, circuits and other directions, and can solve the problems of increasing the preparation cost, multi-component impurities, etc., and achieve the effects of low cost, good performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A kind of technology that prepares sodium ion electrode material with jarosite and bile vitriol, comprises the following steps:

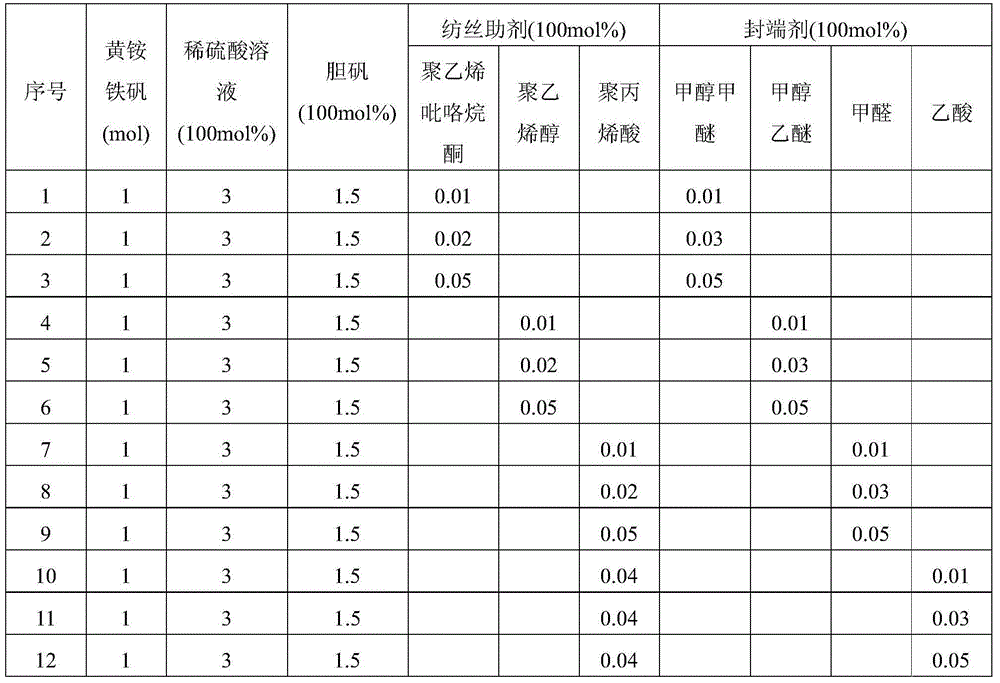

[0016] (1) add dilute sulfuric acid solution in jarosite, stir until jarosite is dissolved, add gallosite, after stirring evenly, add spinning aid and end-capping agent, obtain precursor sol (recipe is shown in Table 1); It is the industrial waste discharged from the zinc smelter;

[0017] (2) Concentrating the precursor sol at 60°C;

[0018] (3) Put the concentrated precursor sol into the centrifugal spinning machine, and obtain the electrode material cotton precursor by centrifugal spinning process;

[0019] (4) The electrode material cotton precursor was dried, then heated to 900°C for firing in a protective atmosphere generated by the decomposition of kerosene or diesel, and kept for 6 hours to obtain a cotton-like sodium ion electrode material.

[0020] Using the fiber cotton as the negative electrode and sodium as the counter electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com