A Compact Layout External Cavity Feedback Diode Laser Spectral Synthesis Optical System

A diode laser and external cavity feedback technology, applied in the field of lasers, can solve problems such as the compact and miniaturized design of the laser system, the large focal length of the slow-axis conversion lens, and the limitation of direct application fields, and achieve excellent engineering practical effects, guarantee efficiency and Quality, optimized effect of compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

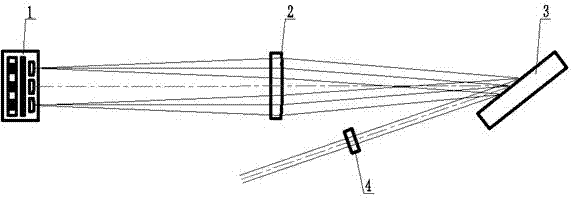

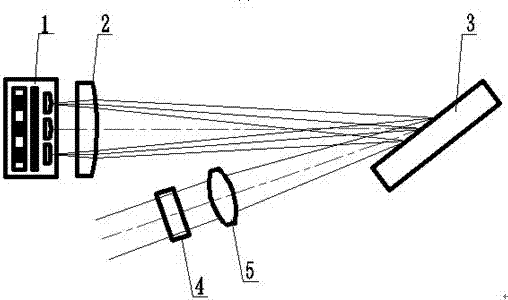

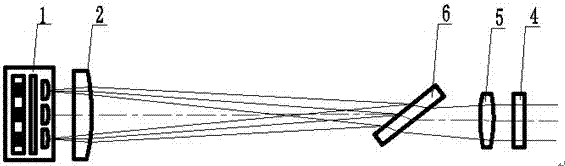

[0020] Such as figure 1 Shown is an ordinary diode laser spectrum synthesis system, which specifically includes a diode laser, a slow-axis conversion cylindrical lens, a reflective plane grating, and an external cavity mirror. Since the diode laser is located on the front focal plane of the slow-axis conversion cylindrical lens, and the reflective plane grating is located on the back focal plane of the slow-axis conversion cylindrical lens, the light emitted by a sub-light-emitting unit in the diode laser is parallel incident after passing through the slow-axis conversion cylindrical lens. to reflective planar gratings. The incident angles of the laser light emitted by different sub-light-emitting units incident on the reflective plane grating are not the same, but because of the different wavelengths, and because of the matching relationship between the incident angle and the wavelength, all the light exits in parallel through the diffraction of the reflective plane grating, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com