Preparation method of chive-flavored flavoring oil

A technology of seasoning oil and chives, which is applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of organic reagent residues, etc., and achieve the effect of short time consumption, fresh and natural fragrance, and pure color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

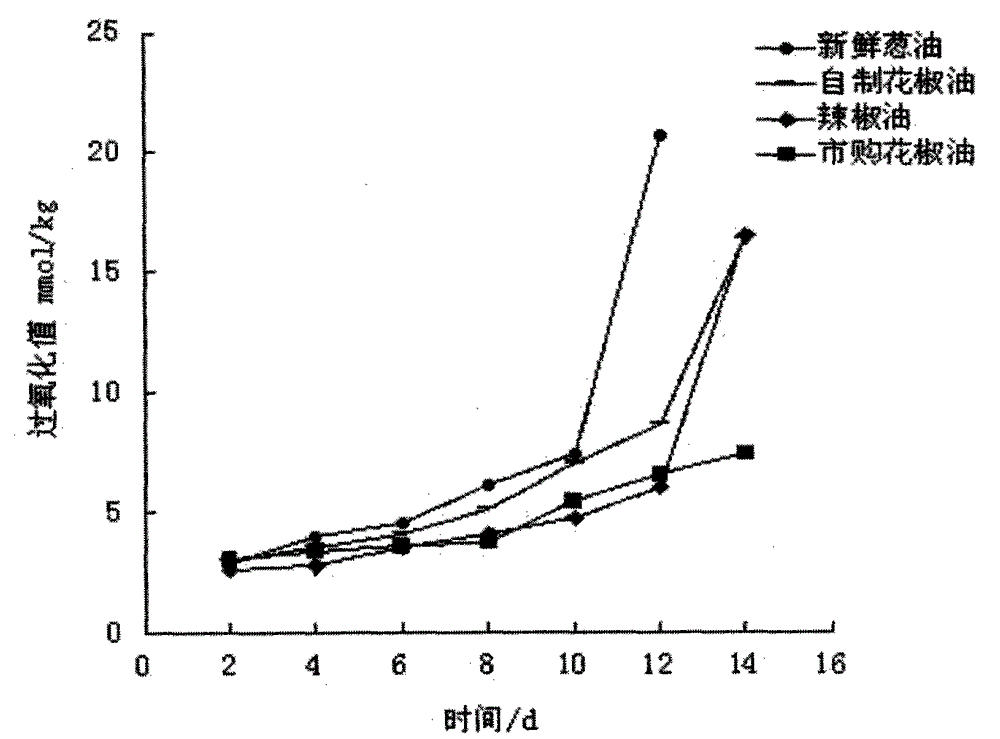

Image

Examples

Embodiment 1

[0026] The concrete steps of the preparation method of shallot flavor seasoning oil of the present invention are as follows:

[0027] (1) Peel and clean the fresh shallots, and use a beater to crush the shallots to make shallot pulp;

[0028] (2) Mix edible soybean oil and green onion pulp in a ratio of 1:1 by weight, and vibrate evenly;

[0029] (3) Shake the raw material obtained in step (2) with a constant temperature water bath for 3 hours at a temperature of 35° C. and a rotating speed of 100 r / min, so that the volatile aroma substances of shallots are fully absorbed;

[0030] (4) Carry out suction filtration with vacuum suction filter then, remove scallion residue and obtain scallion oil mixture;

[0031] (5) Centrifuge the scallion oil mixture at 3000r / min for 20min with a centrifuge, take the upper layer oil of the oil-water separation liquid, and obtain a seasoning oil product with a fresh scallion fragrance;

[0032] (6) With the weight ratio of the additive and th...

Embodiment 2

[0035] The concrete steps of the preparation method of shallot flavor seasoning oil of the present invention are as follows:

[0036] (1) Peel and clean the fresh shallots, and use a beater to crush the shallots to make shallot pulp;

[0037] (2) Mix edible soybean oil and scallion pulp in a ratio of 3:1 by weight, and vibrate evenly;

[0038] (3) Shake the raw material obtained in step (2) with a constant temperature water bath for 1 hour at a temperature of 55° C. and a rotating speed of 150 r / min, so that the volatile aroma substances of shallots are fully absorbed;

[0039] (4) Carry out suction filtration with vacuum suction filter then, remove scallion residue and obtain scallion oil mixture;

[0040] (5) Centrifuge the scallion oil mixture at 5000r / min with a centrifuge for 10min, take the upper layer oil of the oil-water separation liquid, and obtain a seasoning oil product with a fresh scallion fragrance;

[0041] (6) With the weight ratio of the additive and the se...

Embodiment 3

[0044] The concrete steps of the preparation method of shallot flavor seasoning oil of the present invention are as follows:

[0045] (1) Peel and clean the fresh shallots, and use a beater to crush the shallots to make shallot pulp;

[0046] (2) Mix edible soybean oil and green onion pulp in a ratio of 2:1 by weight, and vibrate evenly;

[0047] (3) Shake the raw material obtained in step (2) with a constant temperature water bath for 2 hours at a temperature of 45° C. and a rotating speed of 120 r / min, so that the volatile aroma substances of shallots are fully absorbed;

[0048] (4) Carry out suction filtration with vacuum suction filter then, remove scallion residue and obtain scallion oil mixture;

[0049] (5) Centrifuge the scallion oil mixture at 4000r / min with a centrifuge for 15min, take the upper layer oil of the oil-water separation liquid, and obtain a seasoning oil product with a fresh scallion fragrance;

[0050] (6) Add the additive Zanthoxylum bungeanum oil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com