High-power ultrasonic efficient defoaming device

A defoaming device, ultrasonic technology, applied in the direction of foam dispersion/prevention, etc., can solve problems such as easy adhesion to defoaming equipment, potential safety hazards, general defoaming effect, etc., to eliminate adverse effects, long service life, and eliminate good bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

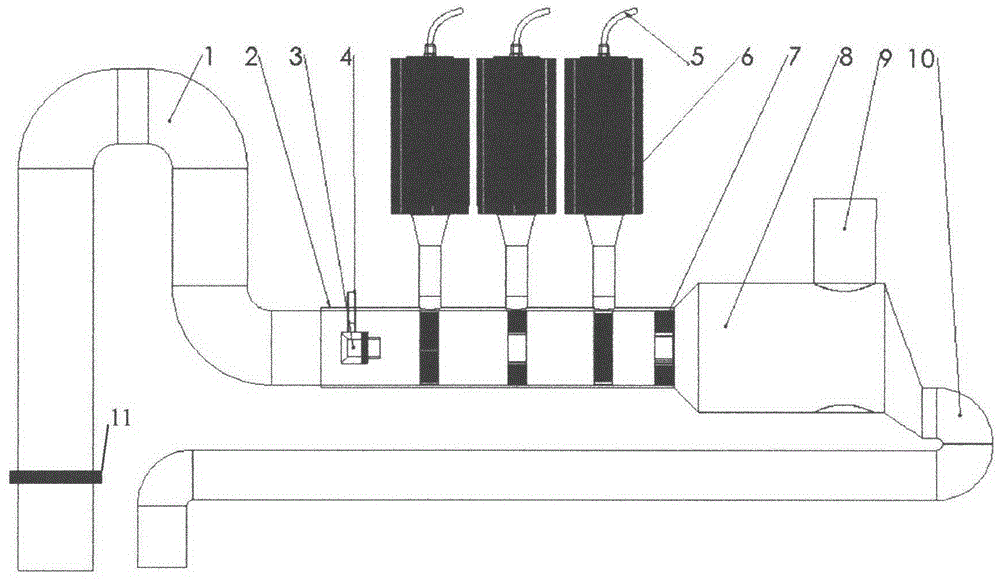

[0030] see figure 1 , which is a structural schematic diagram of Embodiment 1 of the high-power ultrasonic high-efficiency defoaming device of the present invention. As shown in the figure: it includes foam suction pipe 1, power ultrasonic defoamer shell 2, jet aspirator 3, compressed air tube 4, control system signal line 5, acoustic energy converter 6, power ultrasonic defoamer 7, air Liquid collector 8, exhaust pipe 9, liquid return pipe 10, foam sensor 11. The front end of the power ultrasonic defoamer housing 2 is connected to the foam suction pipe 1, and the rear end is connected to the gas-liquid collector 8. Several ultrasonic energy converters 6 are welded on the shell 2 of the power ultrasonic defoamer, and the ultrasonic energy converters 6 receive electrical signals 5 to convert electrical energy into mechanical ultrasonic energy. Several power ultrasonic defoamers 7 are installed inside the shell 2 of the power ultrasonic defoamer. The thickness of the elastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com